ByronJ

Well-Known Member

- Joined

- Jul 7, 2012

- Messages

- 365

- Country Flag

SInce starting a business during 2020 I have had little time to use my Land Cruiser. However LC was recently pressed into service to help with our move from Wales to Cornwall and was doing a great job until last week when as I was driving on the A38 LC droppped out of cruise control and the engine just stopped.

I was lucky enough to be able to coast into a layby and could see a lot of smoke coming from the engine compartment. I grabbed a fire extinguisher and opened the bonnet with my heart in my mouth. No flames anywhere but smoke coming from the rocker cover. It turned out that the coolant hose running from the block to the cabin heater had failed close to the block and dumped all the coolant and the engine (1HD-T) had overheated. I think the smoke was the oil vaporising in the head.

No warning lights came on and I guess all the water/steam must have been sucked under LC as I saw and heard nothing amiss until the engine just cut out.

When she cooled down I refilled her with water and started the engine. Sounded like there was a road drill inside. So I switched off and waited to be recovered.

The recovery itself was an adventure as the lowloader was too long to take the tight bend at the bottom of our access lane. So we unloaded LC at the top of the lane and I freewheeled down the hill. With no power steering or brake servo it took serious effort to take the 90 degree bend (stone walls either side) and then another 90 turn into my garage but I made it without hitting anything!

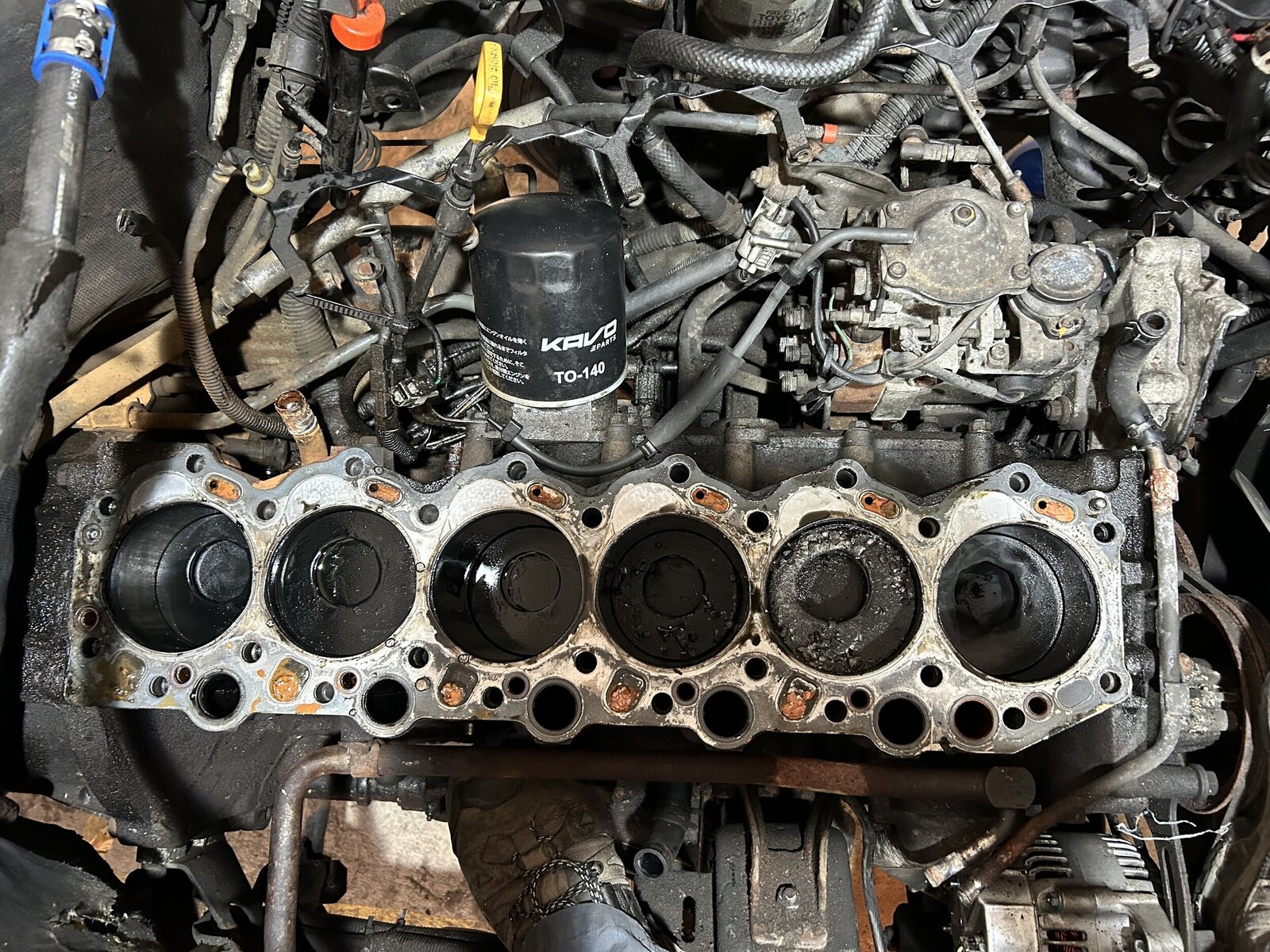

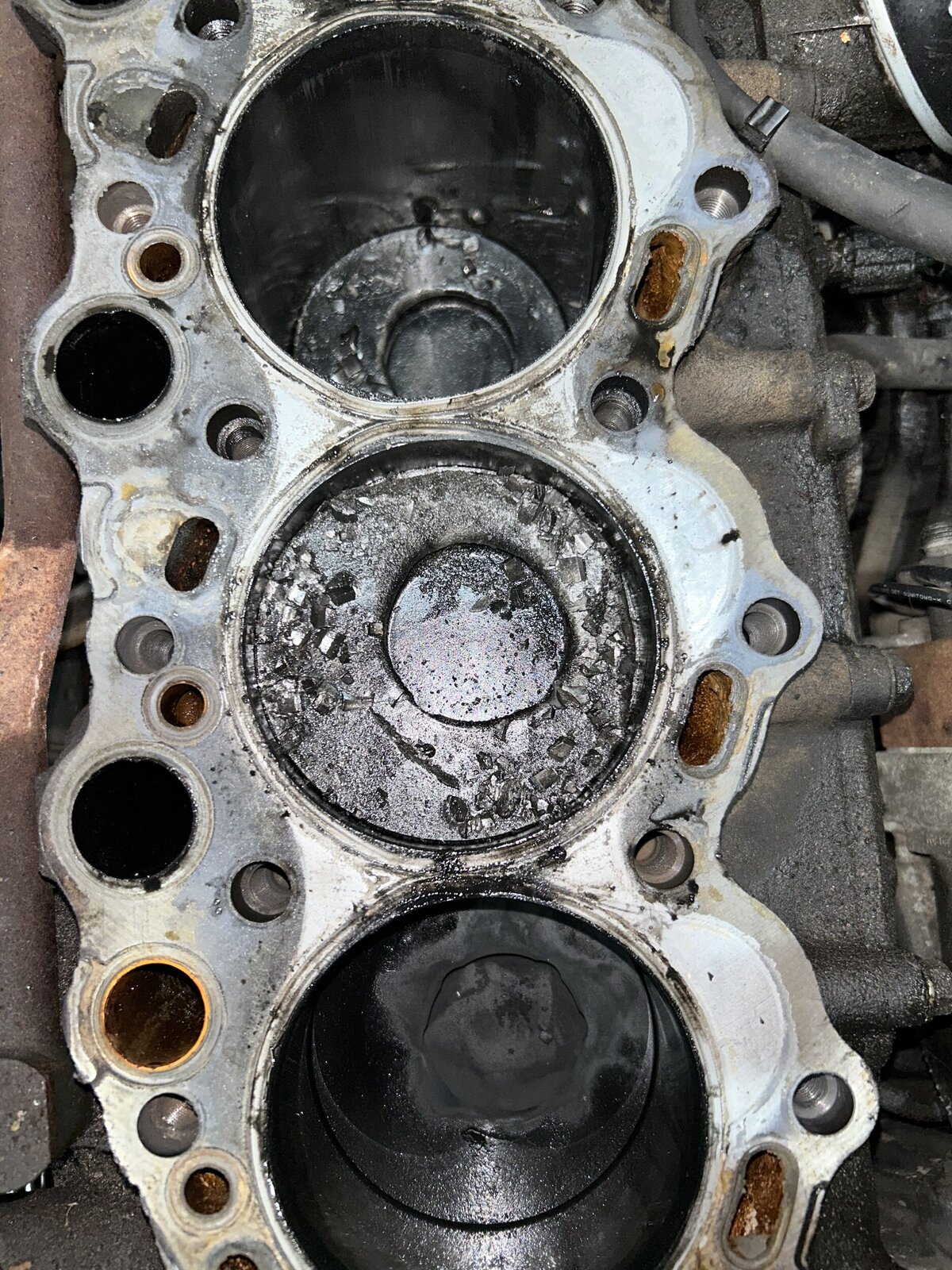

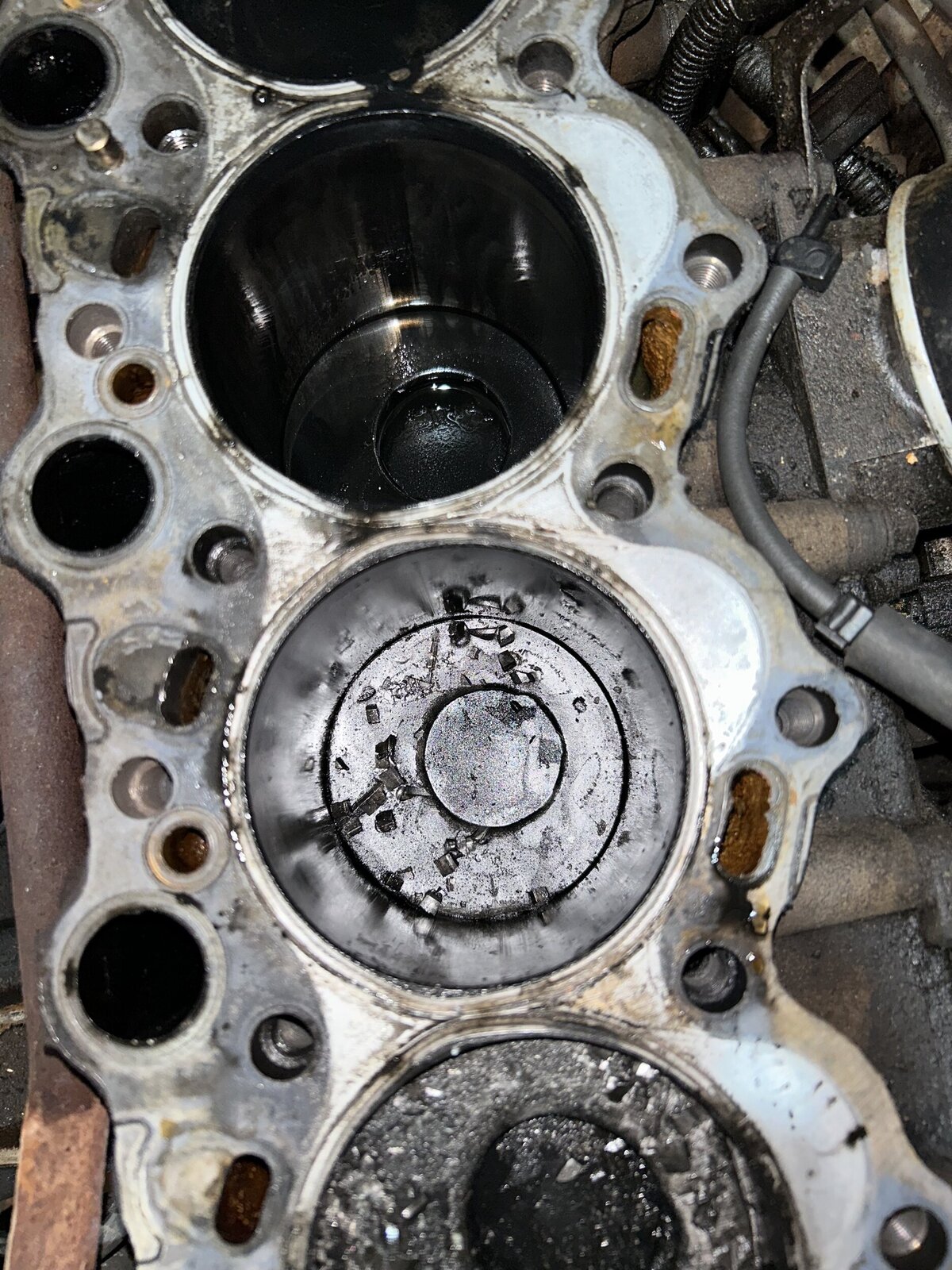

Today I got the head off and this is what I found.

I was lucky enough to be able to coast into a layby and could see a lot of smoke coming from the engine compartment. I grabbed a fire extinguisher and opened the bonnet with my heart in my mouth. No flames anywhere but smoke coming from the rocker cover. It turned out that the coolant hose running from the block to the cabin heater had failed close to the block and dumped all the coolant and the engine (1HD-T) had overheated. I think the smoke was the oil vaporising in the head.

No warning lights came on and I guess all the water/steam must have been sucked under LC as I saw and heard nothing amiss until the engine just cut out.

When she cooled down I refilled her with water and started the engine. Sounded like there was a road drill inside. So I switched off and waited to be recovered.

The recovery itself was an adventure as the lowloader was too long to take the tight bend at the bottom of our access lane. So we unloaded LC at the top of the lane and I freewheeled down the hill. With no power steering or brake servo it took serious effort to take the 90 degree bend (stone walls either side) and then another 90 turn into my garage but I made it without hitting anything!

Today I got the head off and this is what I found.