Scott

Well-Known Member

- Joined

- Mar 17, 2010

- Messages

- 1,046

My Drifta drawer unit and camp kitchen + camp table are still tucked up in storage if anyone is interested https://www.landcruiserclub.net/com...le-camp-kitchen-for-sale.142629/#post-1378090

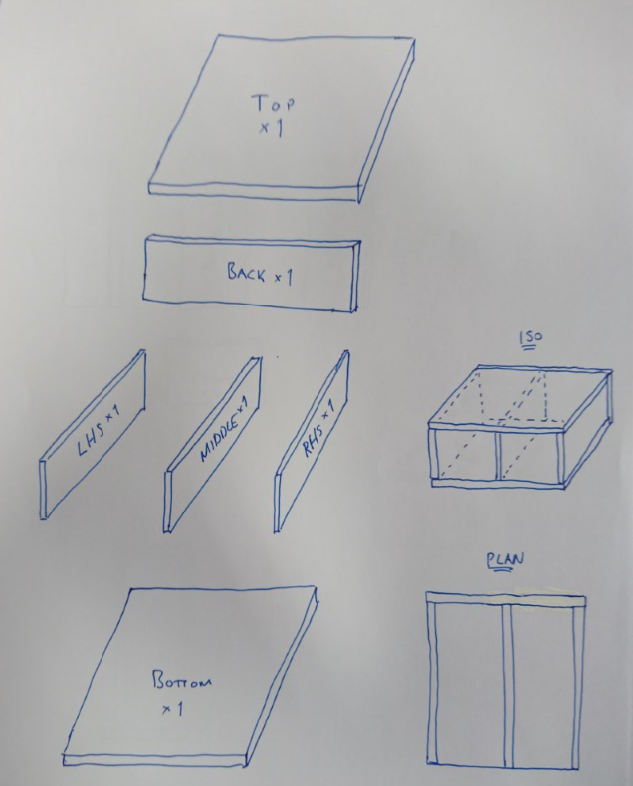

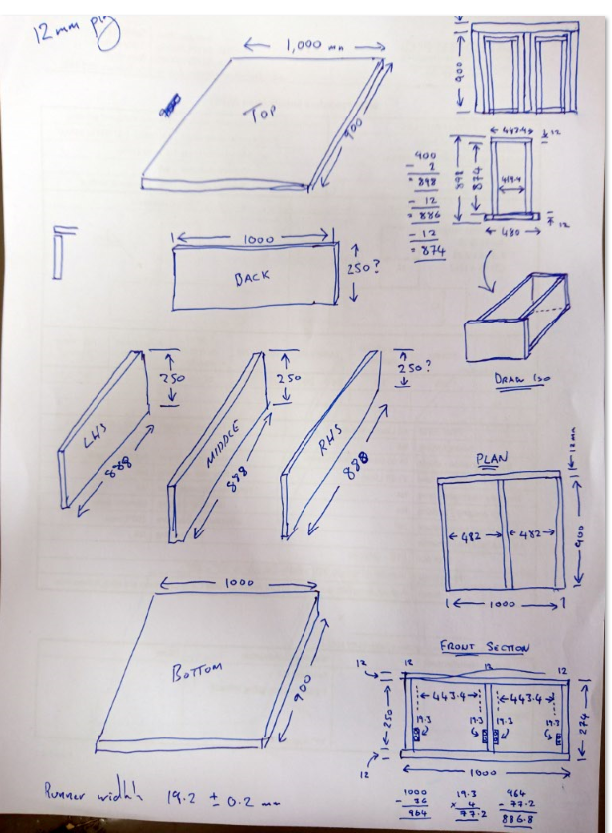

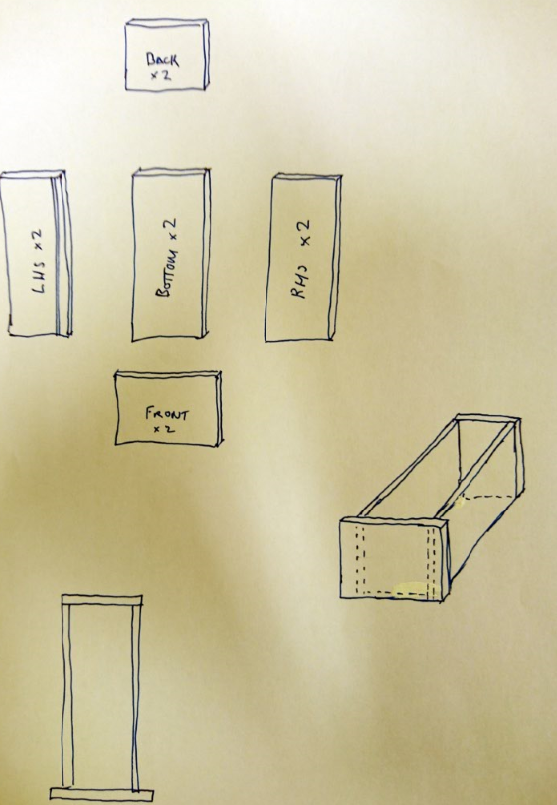

Drifta do a substitute drawer to go in place of the kitchen for day to day use, I wouldn't think it would take too much effort to make a substitute drawer here in the UK.

I decided to keep it incase I needed it, but it still hasn't been used and is in as new condition. Its an impressive bit of kit, craftmanship and design.

Drifta do a substitute drawer to go in place of the kitchen for day to day use, I wouldn't think it would take too much effort to make a substitute drawer here in the UK.

I decided to keep it incase I needed it, but it still hasn't been used and is in as new condition. Its an impressive bit of kit, craftmanship and design.