- Joined

- Feb 2, 2011

- Messages

- 246

- Country Flag

The last playday of the year could have cost dear!................

Normal playday in the main, follow my leader and all that, started to get a little challenging and pushing each other harder, I ended up in the water - up over the bonnet, turns out it was also mud 3/4 up the 37" tyres - lockers in and making slow progress out but needed a lot of to and for shunting with revs around 2500 to get suitable momentum. Momentum got harder as the car filled with water but it only got as deep as the stereo - it seems to have survived electrically - need six months for the terminals to corrode!!

After about 5 mins in I noticed the motor didn't sound right - It had stopped charging almost straight away in the water but that was just the alternator being drowned - the worrying thing was the 1/4 oil pressure reading and only going to just under half when revved - normally I have had good oil pressure with 3/4 reading on the same revs. So a full recovery situation.

Got it onto hard-standing and there was a definitive bottom end knock. So obviously it was turned off, checked the oil and it was ALL the way up the dipstick and fully aerated (looked like when you whisk egg whites) - so dragged it back to the camp site, had a beer or 3 and rechecked - the oil had settled to normal level and no sign of water ingress. Started it back up, no knocking but only 1/4 oil pressure (it never used to go below 1/2 on tick-over).

A trip to Halfords to buy some oil - drained and replenished with mineral 15w 40, much better - normal sounding engine and pressure readings probably 1/8 below what they normally where. Then it got warm and the knocking came back - so there is something not right - engine off. It has only been ran since to get it on and off a mates trailer.

So its fingers crossed that this has just knocked out the BEBs. Ive ordered new ACL from Karl Webster, Ive ordered a set of mains as well (in case its coming out) - the hope being Ive not scored the crank of course.

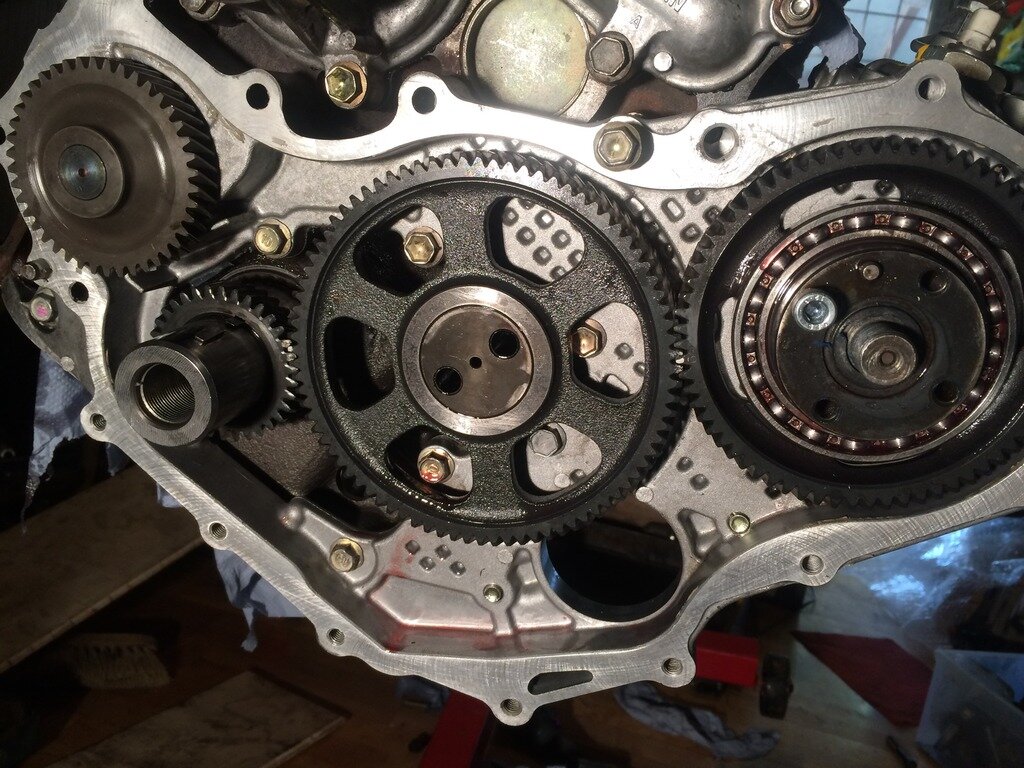

Just doing my homework on oil pump internals (it looks like they can be changed with the front cover off?).

Ive been in much worse situations than this with more heat and abuse to the engine. The only thing "we" can put it down to is the new oil I have put in (Westway Oils 15w40 Semi with genuine Toyota filter) has just failed, perhaps somehow the angle I was at allowed the crank to smash the oil and it aerated?

Thoughts welcomed!

EDIT: The oil was probably 200 miles old at best with a genuine OEM filter).

Normal playday in the main, follow my leader and all that, started to get a little challenging and pushing each other harder, I ended up in the water - up over the bonnet, turns out it was also mud 3/4 up the 37" tyres - lockers in and making slow progress out but needed a lot of to and for shunting with revs around 2500 to get suitable momentum. Momentum got harder as the car filled with water but it only got as deep as the stereo - it seems to have survived electrically - need six months for the terminals to corrode!!

After about 5 mins in I noticed the motor didn't sound right - It had stopped charging almost straight away in the water but that was just the alternator being drowned - the worrying thing was the 1/4 oil pressure reading and only going to just under half when revved - normally I have had good oil pressure with 3/4 reading on the same revs. So a full recovery situation.

Got it onto hard-standing and there was a definitive bottom end knock. So obviously it was turned off, checked the oil and it was ALL the way up the dipstick and fully aerated (looked like when you whisk egg whites) - so dragged it back to the camp site, had a beer or 3 and rechecked - the oil had settled to normal level and no sign of water ingress. Started it back up, no knocking but only 1/4 oil pressure (it never used to go below 1/2 on tick-over).

A trip to Halfords to buy some oil - drained and replenished with mineral 15w 40, much better - normal sounding engine and pressure readings probably 1/8 below what they normally where. Then it got warm and the knocking came back - so there is something not right - engine off. It has only been ran since to get it on and off a mates trailer.

So its fingers crossed that this has just knocked out the BEBs. Ive ordered new ACL from Karl Webster, Ive ordered a set of mains as well (in case its coming out) - the hope being Ive not scored the crank of course.

Just doing my homework on oil pump internals (it looks like they can be changed with the front cover off?).

Ive been in much worse situations than this with more heat and abuse to the engine. The only thing "we" can put it down to is the new oil I have put in (Westway Oils 15w40 Semi with genuine Toyota filter) has just failed, perhaps somehow the angle I was at allowed the crank to smash the oil and it aerated?

Thoughts welcomed!

EDIT: The oil was probably 200 miles old at best with a genuine OEM filter).

Last edited: