- Joined

- Feb 2, 2013

- Messages

- 16,202

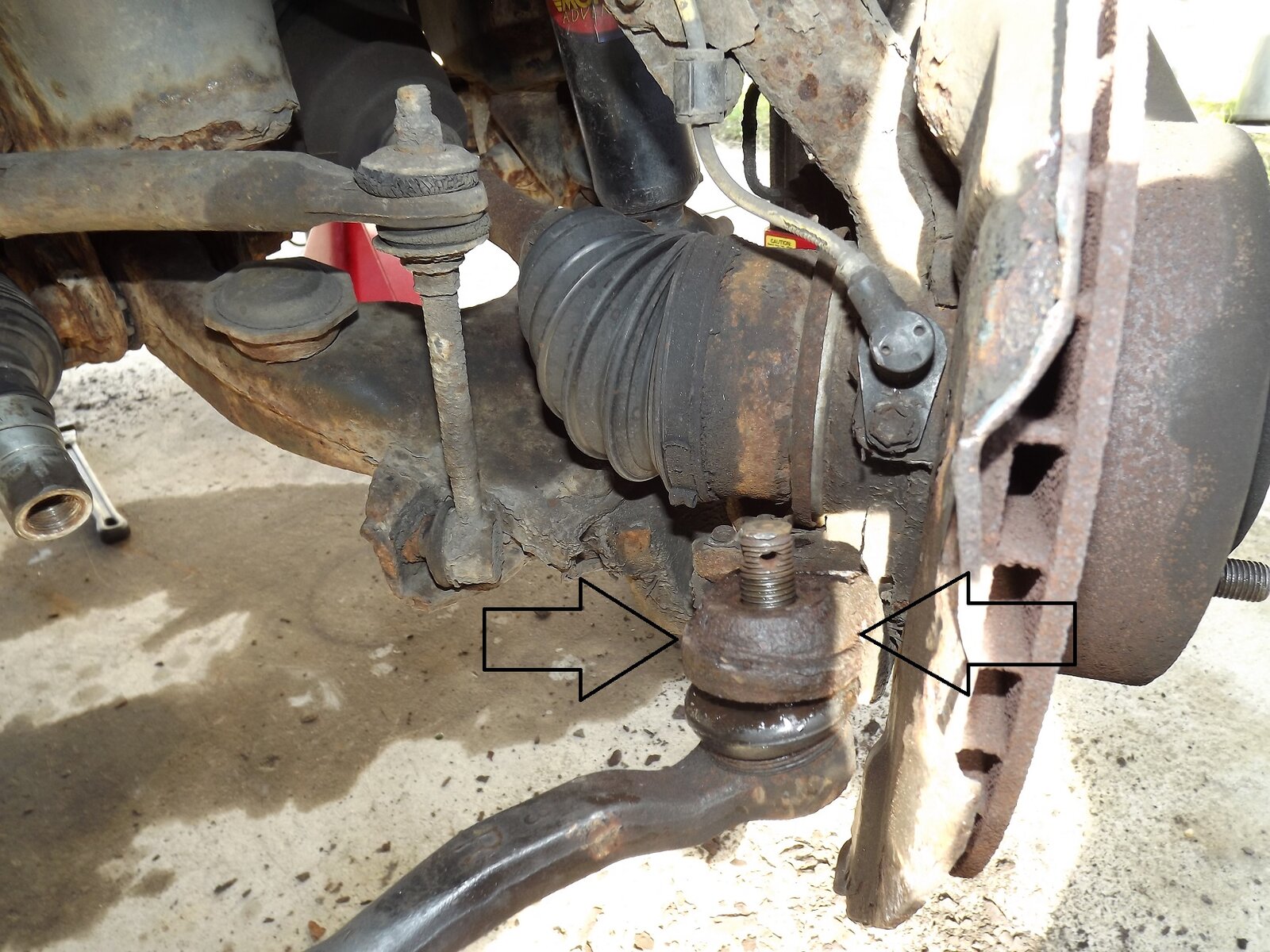

I can't get them out of the knuckle the taper has seized solid , searching for tools this is the only thing to present itself

Which doesn't really look very promising .

I'm about to take a grinder to it as its the only way i can see to get some heat in there but will i regret it ?

Any suggestions welcome .

Which doesn't really look very promising .

I'm about to take a grinder to it as its the only way i can see to get some heat in there but will i regret it ?

Any suggestions welcome .

....................

....................