barkev

Active Member

- Joined

- Jul 31, 2022

- Messages

- 56

- Country Flag

Guys I need opinions.

Mechanic passed away tragically, cancer

mId-engine build. He didn't tell anyone!

.

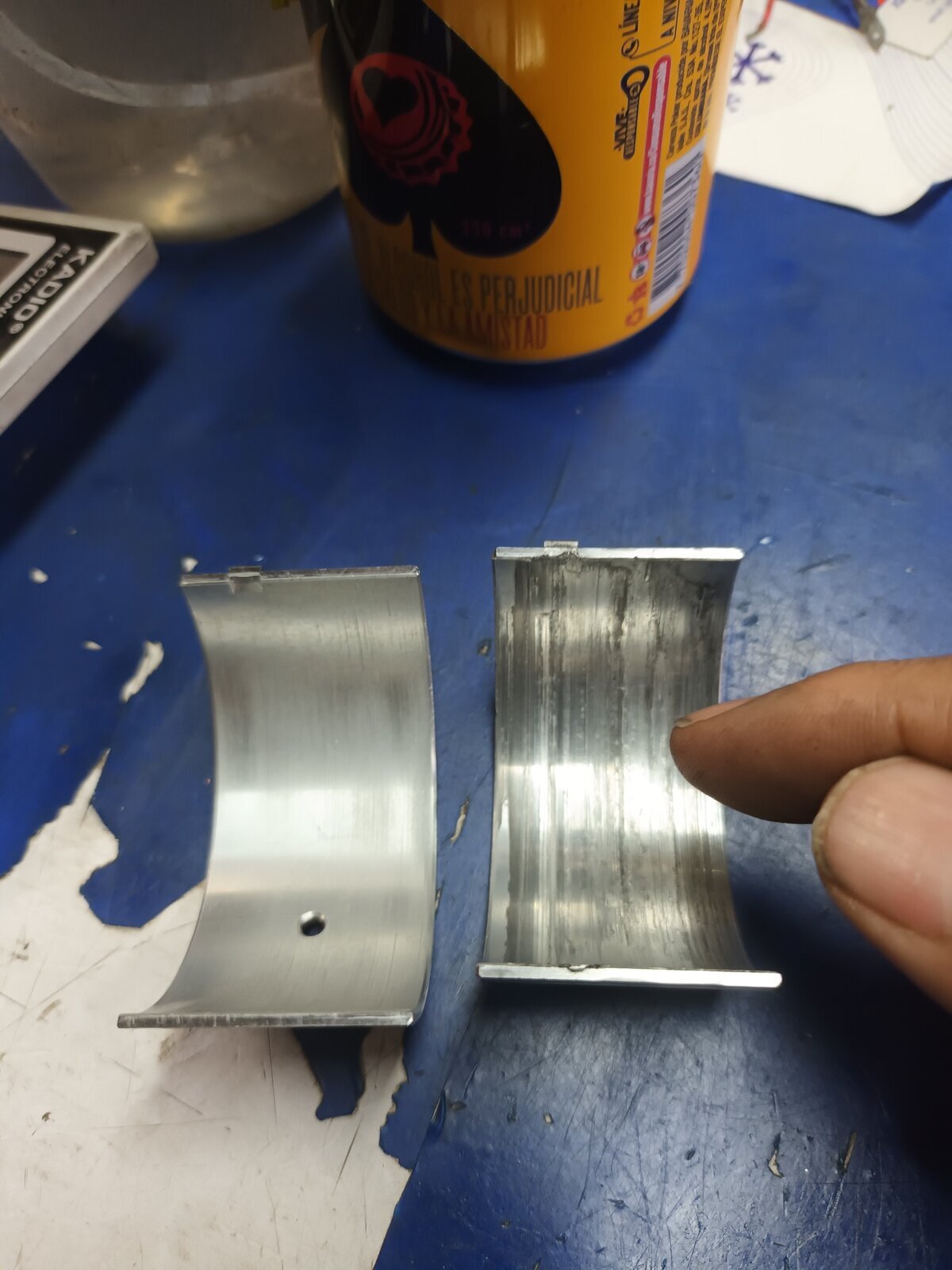

So the pix...he did the top end, and I'm assuming he did the rod bearings because they looked new when I pulled the crankcase and had them out.

The reason I pulled them? Oil wasn't getting to the top, at first I thought oil pump ... then spun bearing and there it was!

If you compare the baddie with a good one - there's a tiny hole for lubricant - on the bad one the hole doesn't go all the way through. I'm guessing that's was caused the scoring.

So I replaced them all. But should I grind the crankshaft as well ?

Or did I dodge the bullet on the bottom end?

.

Mechanic passed away tragically, cancer

mId-engine build. He didn't tell anyone!

.

So the pix...he did the top end, and I'm assuming he did the rod bearings because they looked new when I pulled the crankcase and had them out.

The reason I pulled them? Oil wasn't getting to the top, at first I thought oil pump ... then spun bearing and there it was!

If you compare the baddie with a good one - there's a tiny hole for lubricant - on the bad one the hole doesn't go all the way through. I'm guessing that's was caused the scoring.

So I replaced them all. But should I grind the crankshaft as well ?

Or did I dodge the bullet on the bottom end?

.

Attachments

Last edited: