hi all,

gav no mate wont spoil it, im right up to date

right, with the camper back in the garage, it was time to start on the rear kitchen door, we have discussed this part to some end, and decided that a door that opens upward in true tear drop style will have another benefit, i can used the roof above my head as a frame for an awning, two poles that hold the door up will be the corner posts giving me an area of about 1.5 x 1.8 and what ever the roof finishes at

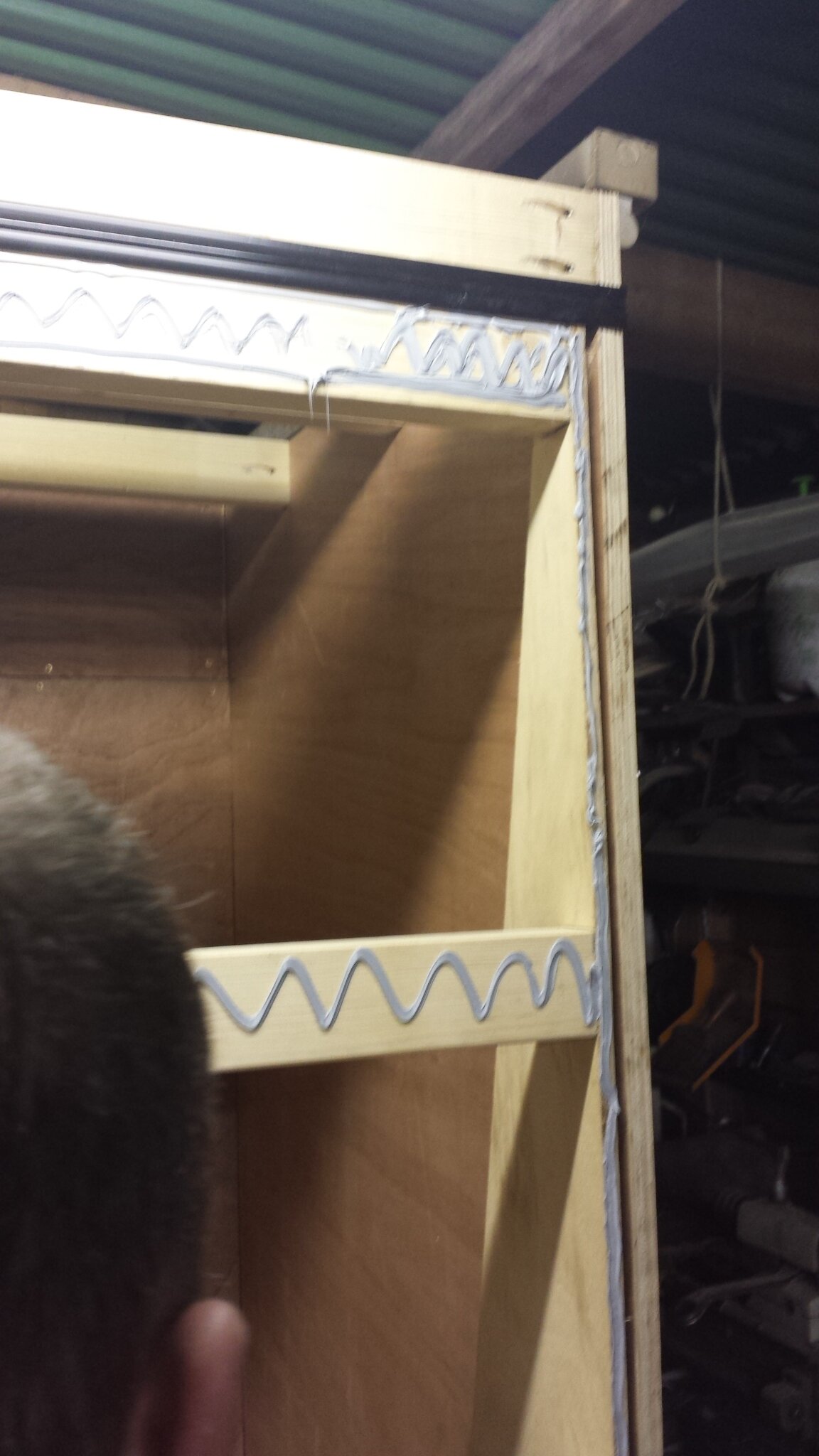

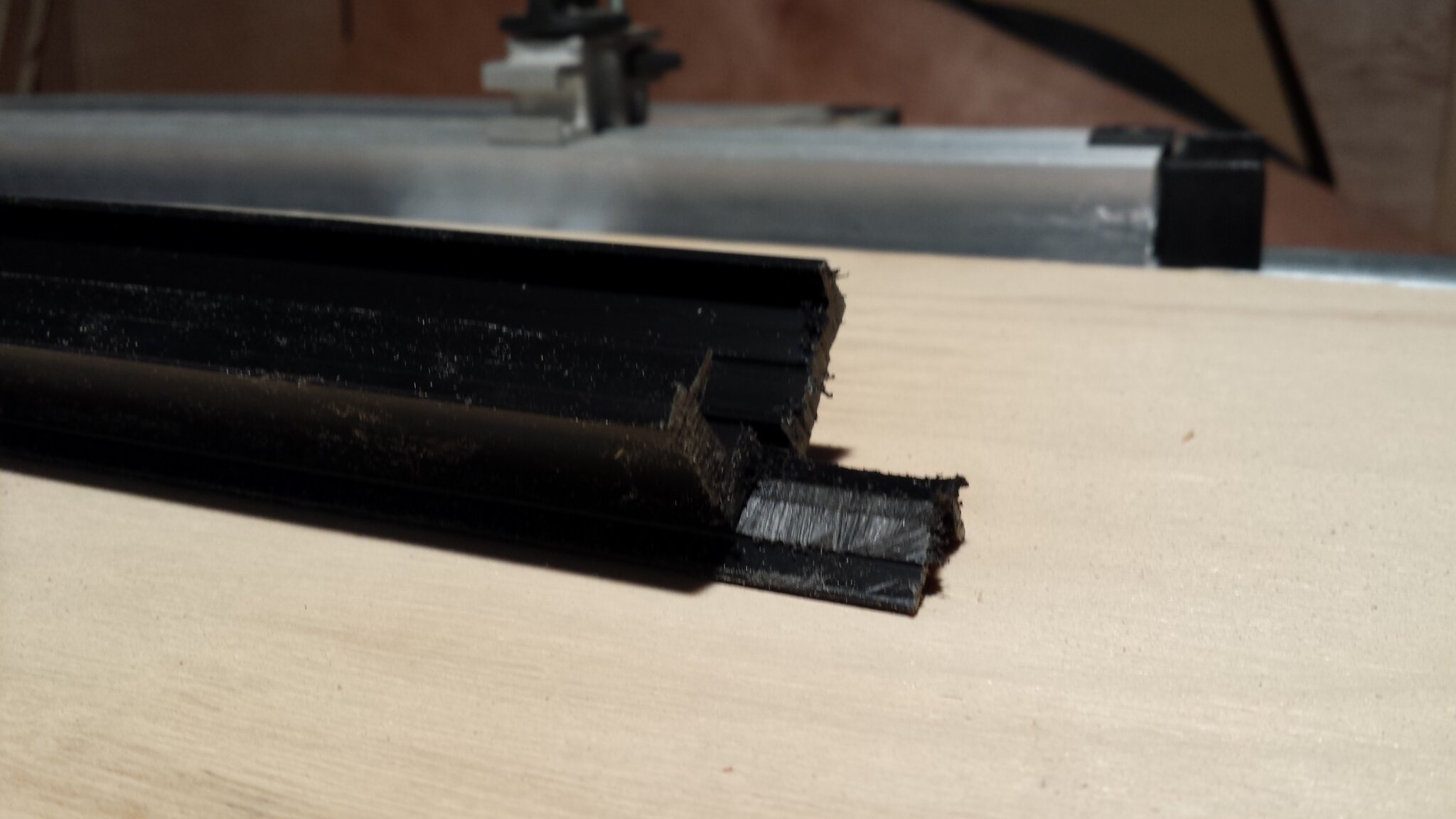

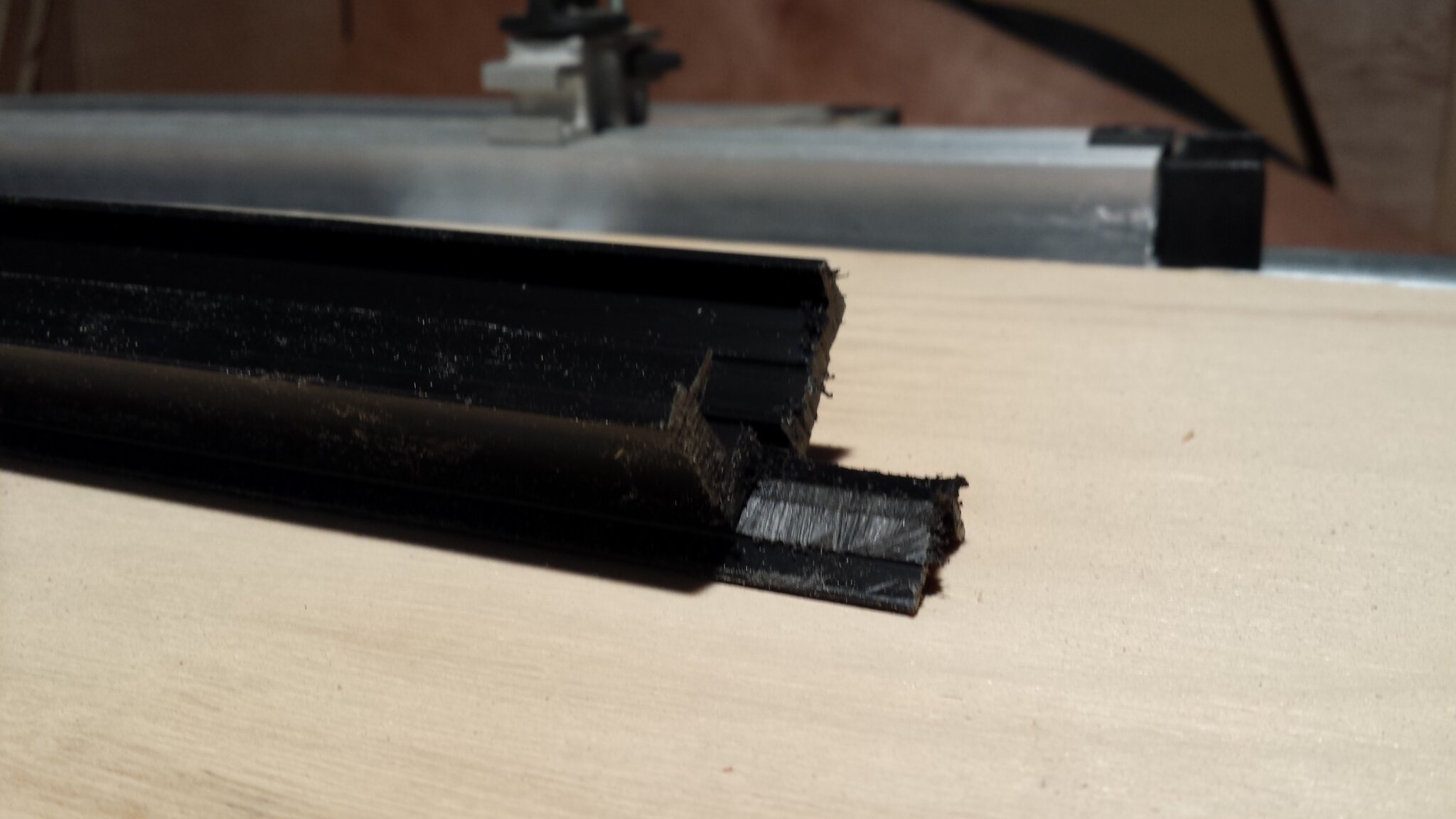

im trailing a new hinge at the moment its made of extrusion plastic with a rubber strip fixed at the centre, has been tested at 50,000 cycles and can carry 150kg over 1m length so should its well within my specs

any way some pics

we have cut the hinge like this so we get an overlap on to the sides, we can seal this with a p seal

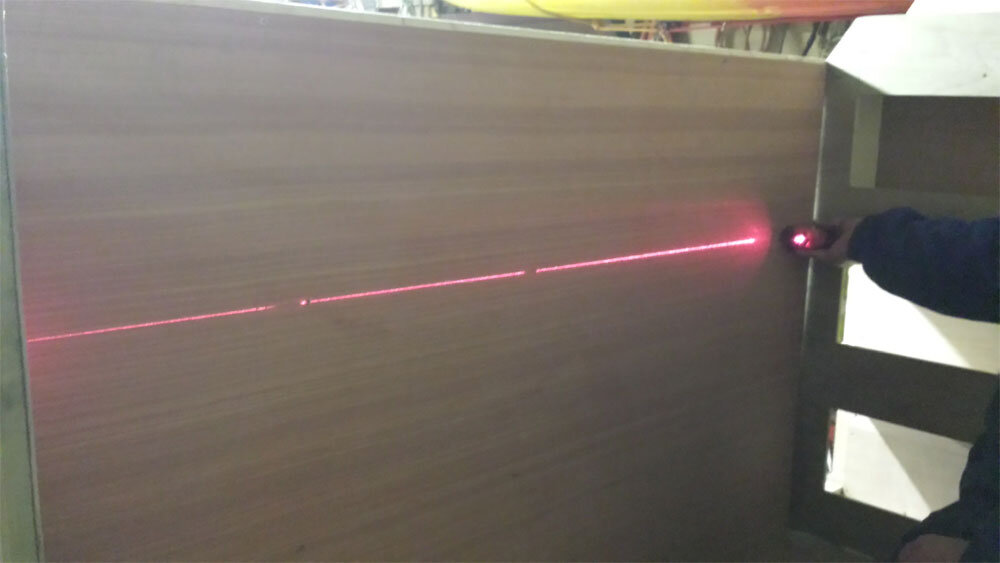

im not taking any chances so we drilled/countersunk out the hinge every 100mm, then applied sika stickaflex

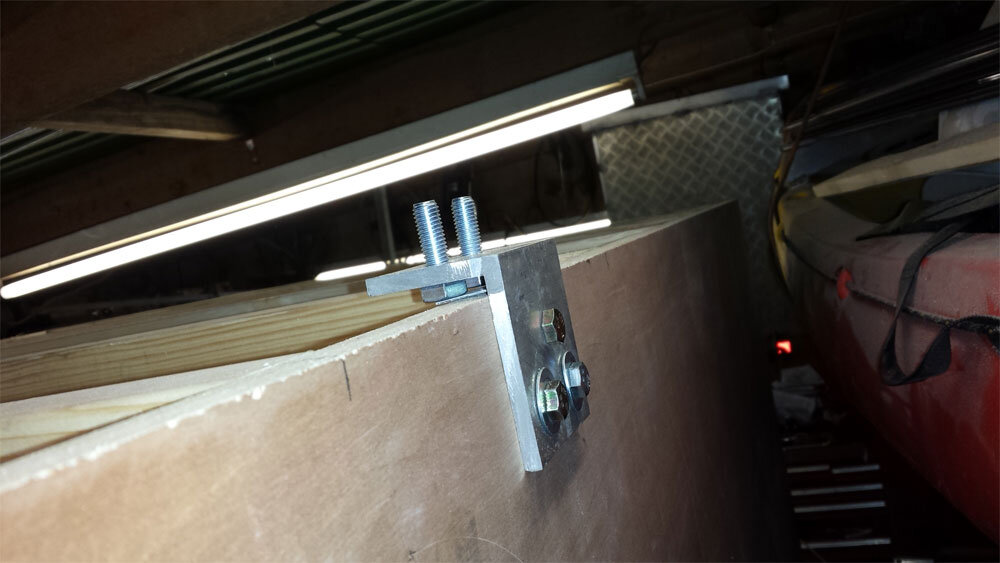

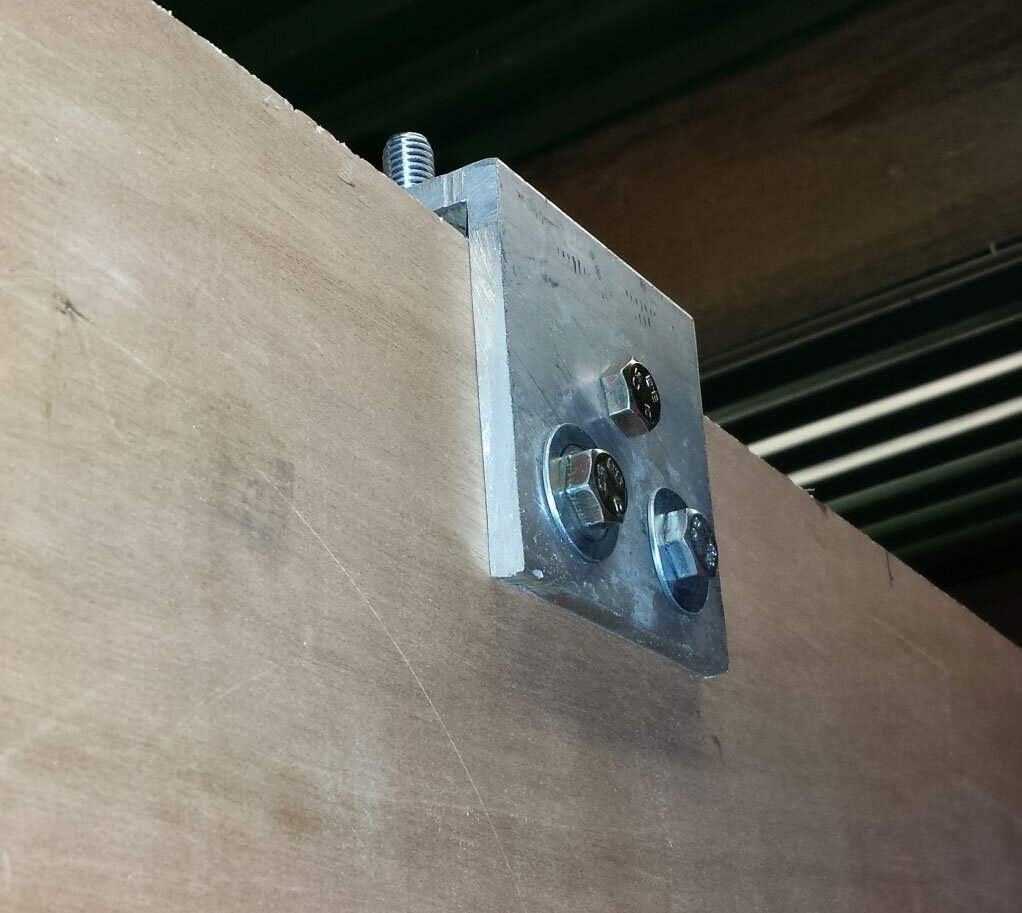

the ally piece you can see is a spacer, the bottom sheet is fitted under the lip on the hinge, the top sheet that comes over the top overlaps the top part of the hinge, it just to guarantee our seal

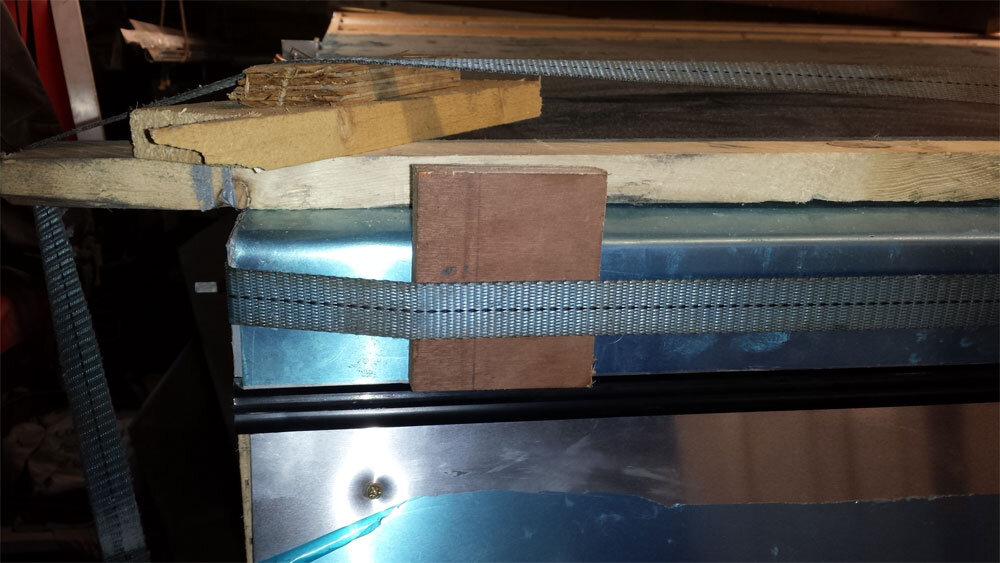

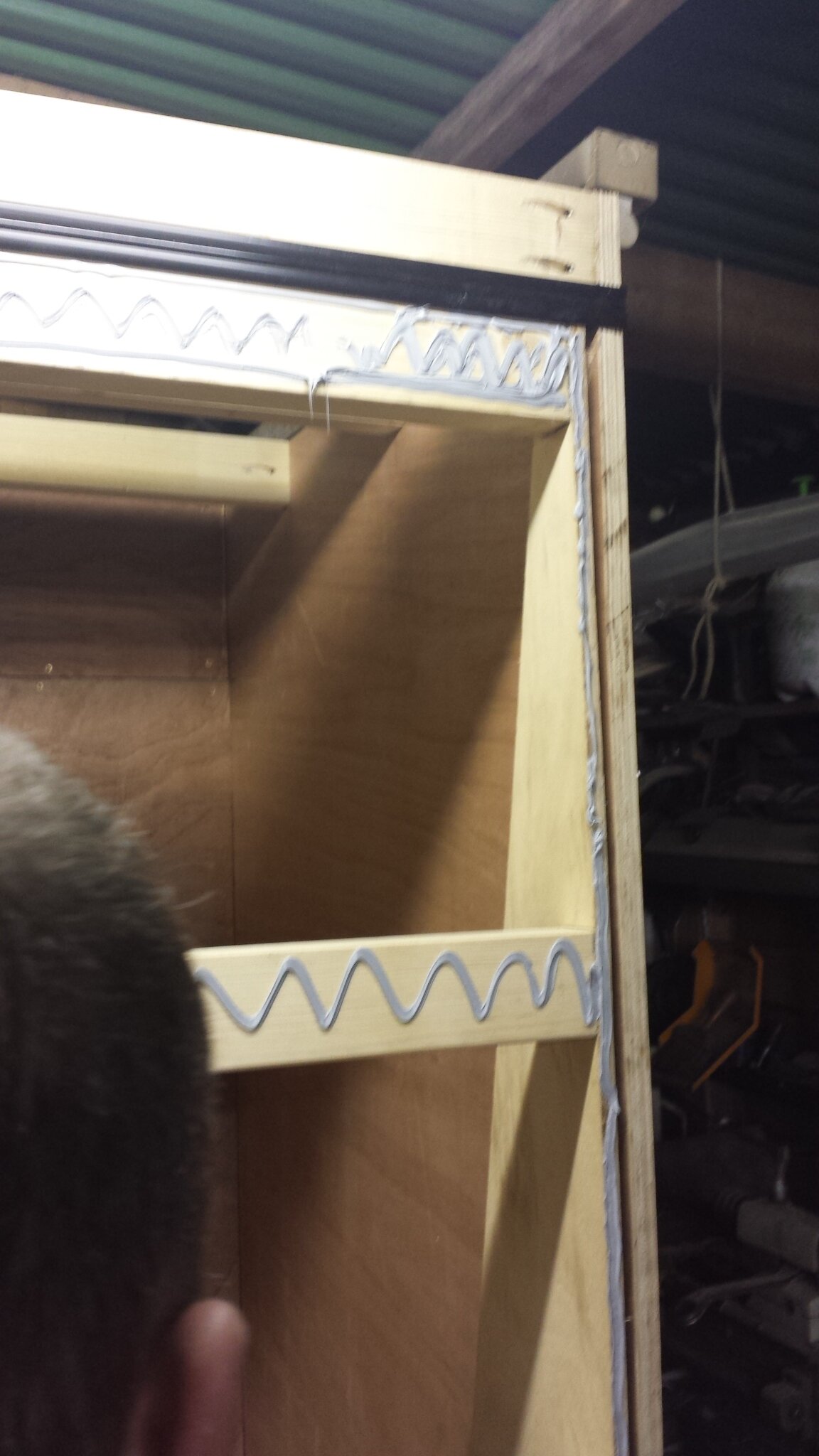

we cant build this on the bench as we want a custom fit to our rear, and this can only be achieved instu, we have packed out both sides to about 5mm and hung the top timber on the hinge and well here is the pics

the ply profile is the door ends so to speak we can afford to screw through here as the heads will not be seen

i have missed a few pics here in my hast, basically we fitted the bottom timber the filled in the rest, a couple of the timber had to be cut at 45 degrees as one is need on the upper corner and the one below which ties into the floor

the hinge works as it should but we keep testing to see if there is any bind

we use plenty of stickaflex here as were not using any fixings, we then rub stikaflex into the edges to seal ply

then fix the first sheet,

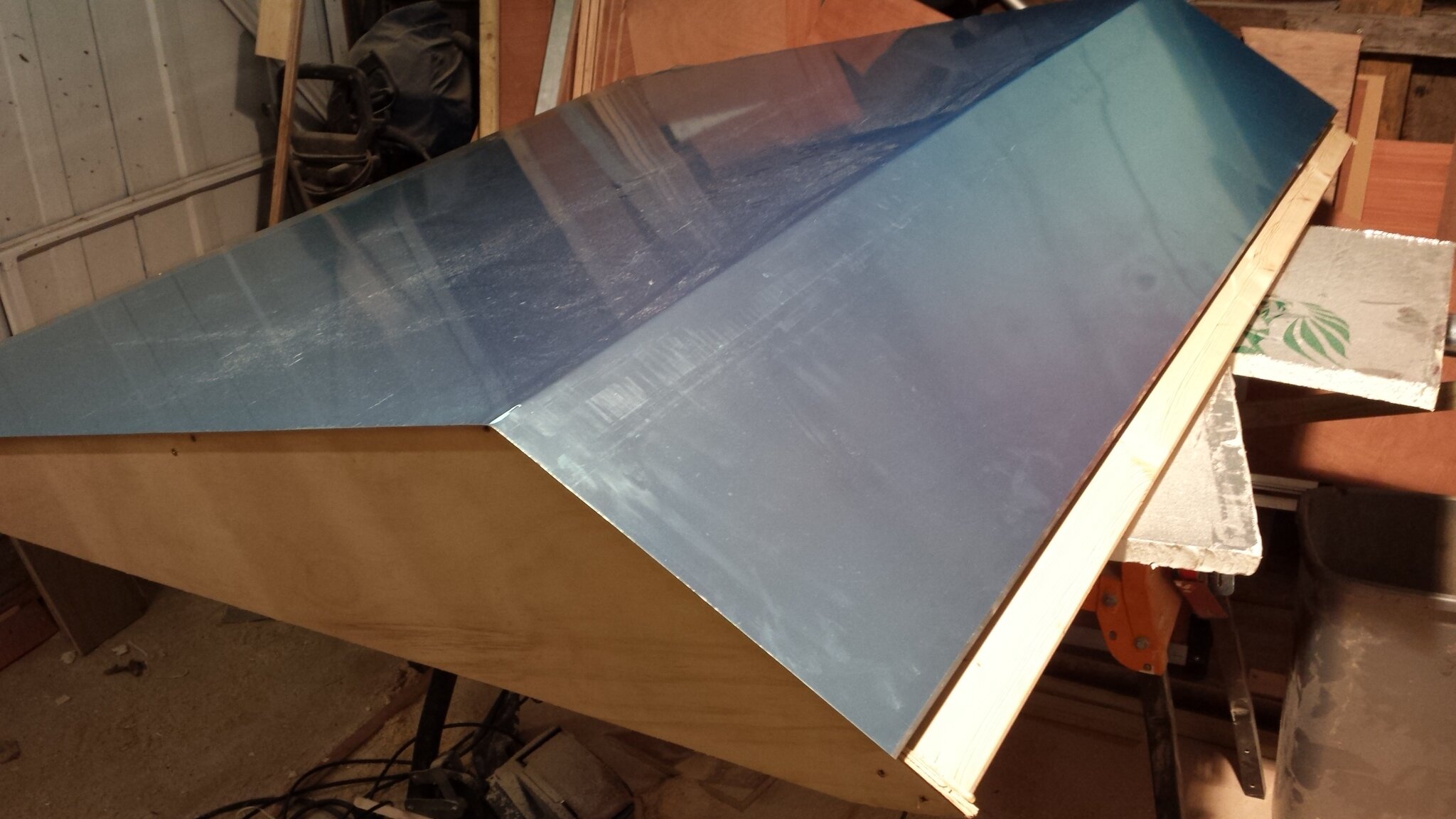

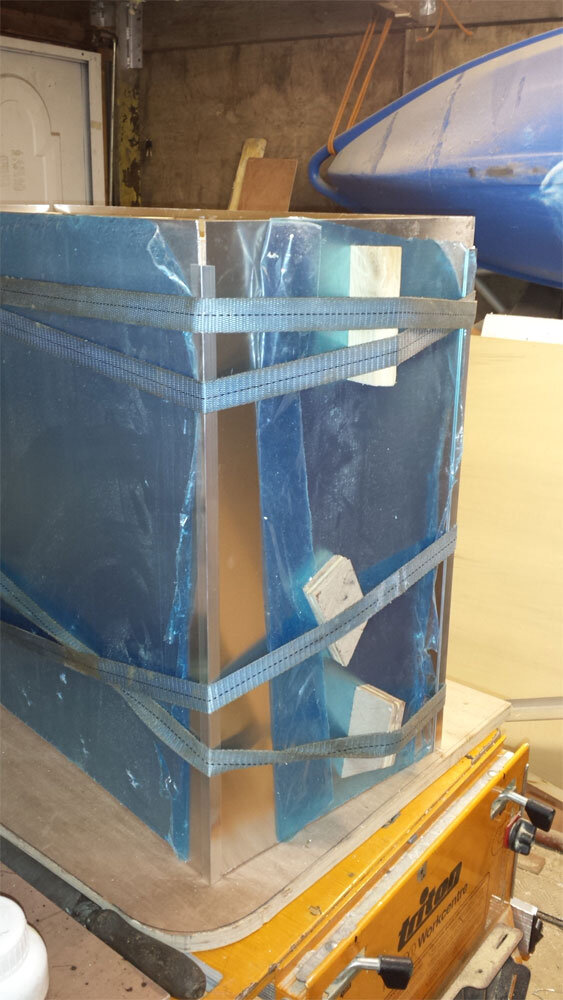

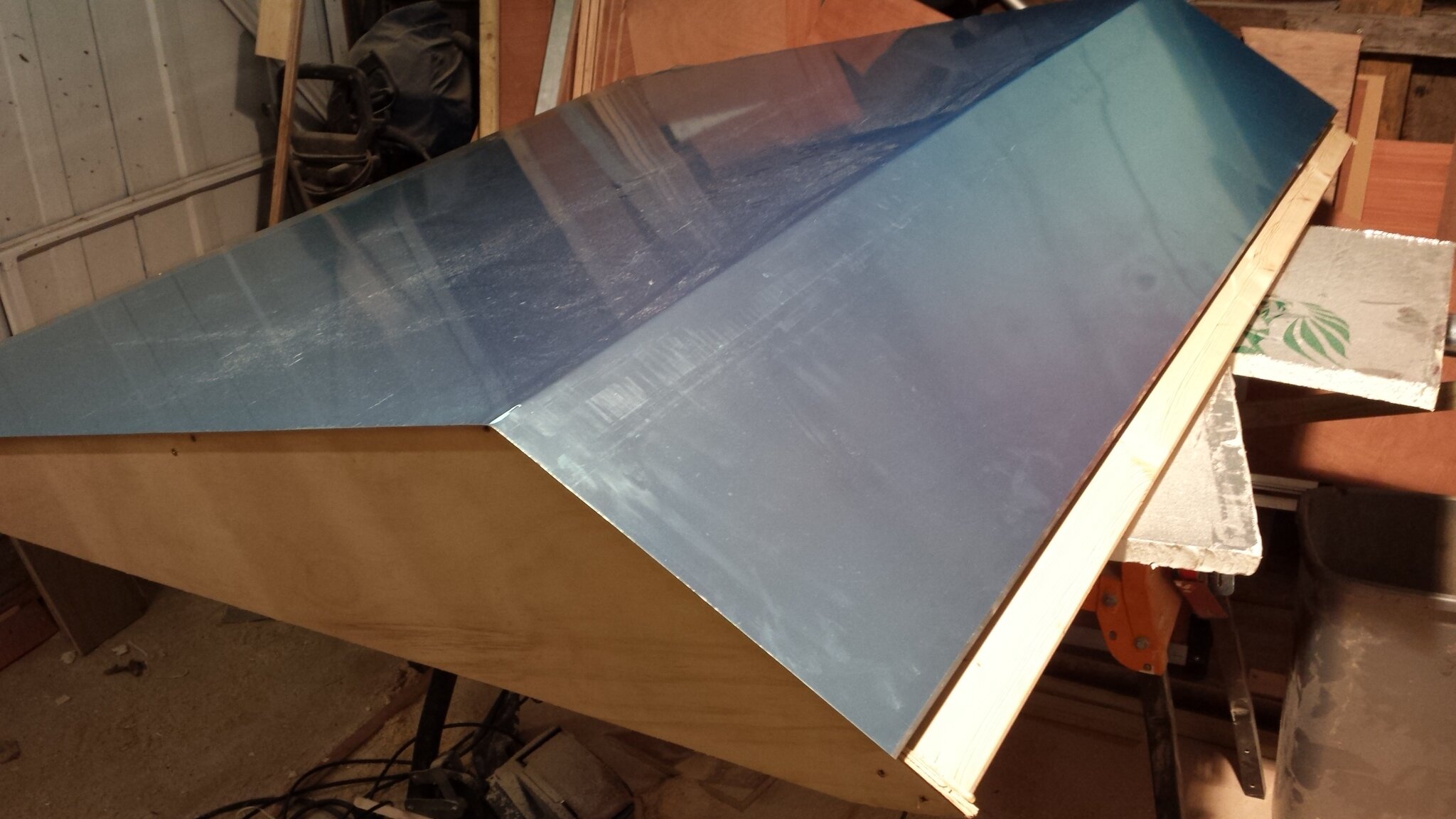

im using .9 ally sheet here, the blue colour is the protective coating, only costs a couple of pence, helps in a tight garage

i have only glued the top half as i have to bend the lower half manually when the glue goes off, its just a lot easier, keeps flex to a minimum,

this is the top sheet folded over 70mm and we have a 10mm overlap over top of the hinge, this bend had to be spot on as an deviation here throws it out on the opposite end of the sheet, should have took a pic i had 8 g clamps lined up for the bending

i took the rear door off today and finished the bending, i know its short, but i have an 80mm drip strip to fit and clean it up

thats the front end glued , again only up to the first bend,

back to work on monday so things will be going a bit slower now,

catch you all later

the ply profile is the door ends so to speak we can afford to screw through here as the heads will not be seen

the ply profile is the door ends so to speak we can afford to screw through here as the heads will not be seen

i have missed a few pics here in my hast, basically we fitted the bottom timber the filled in the rest, a couple of the timber had to be cut at 45 degrees as one is need on the upper corner and the one below which ties into the floor

i have missed a few pics here in my hast, basically we fitted the bottom timber the filled in the rest, a couple of the timber had to be cut at 45 degrees as one is need on the upper corner and the one below which ties into the floor