Hello all

I need to tighten the dual drive belts (alternator) but the process is too simple for anyone to have documented it for a fool.

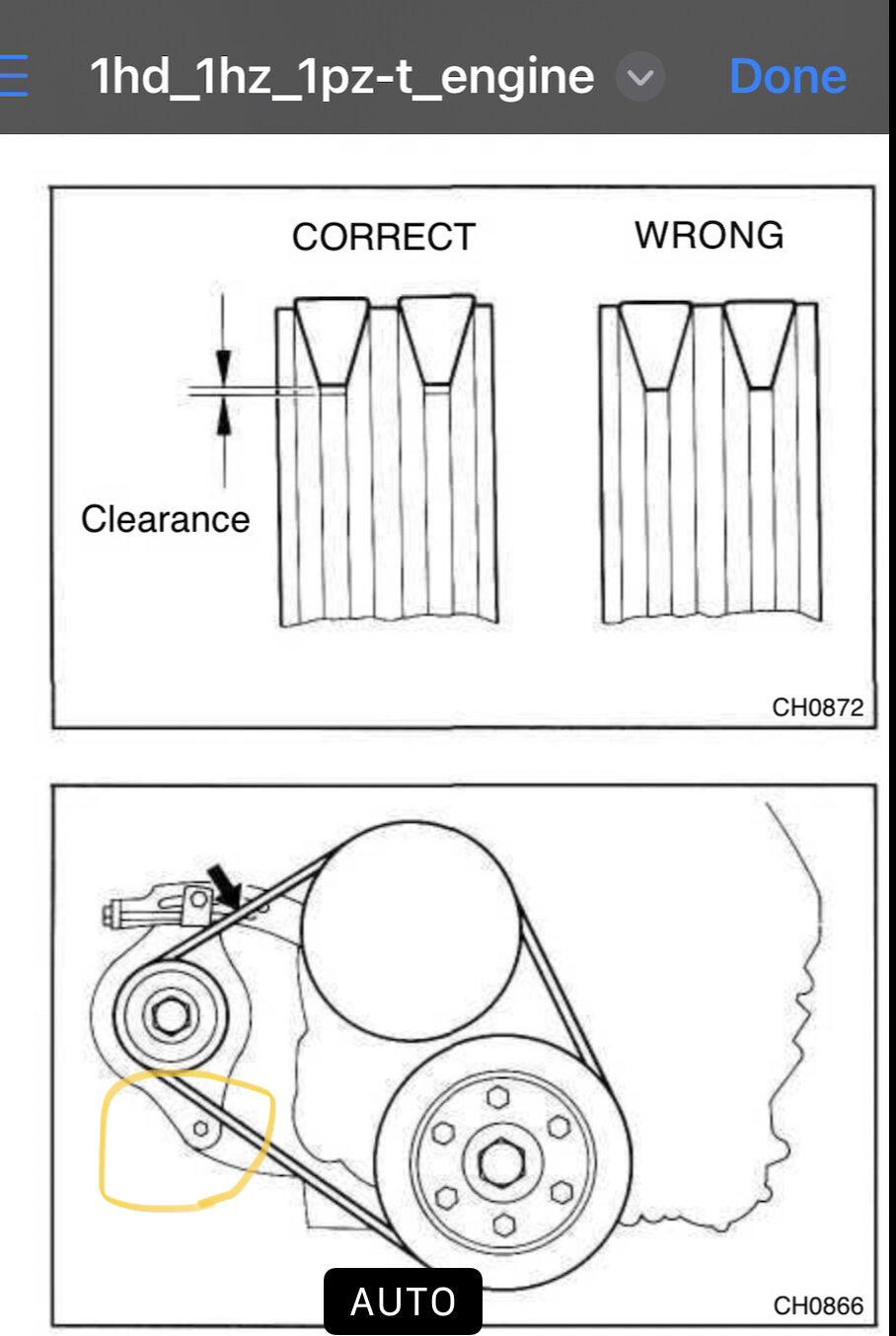

The Toyota maintenance manual does nt even mention it. So as per the diagram - do first loosen the lower alternator nut (highlighted in yellow) then turn the horizontal adjustment bolt at the top?

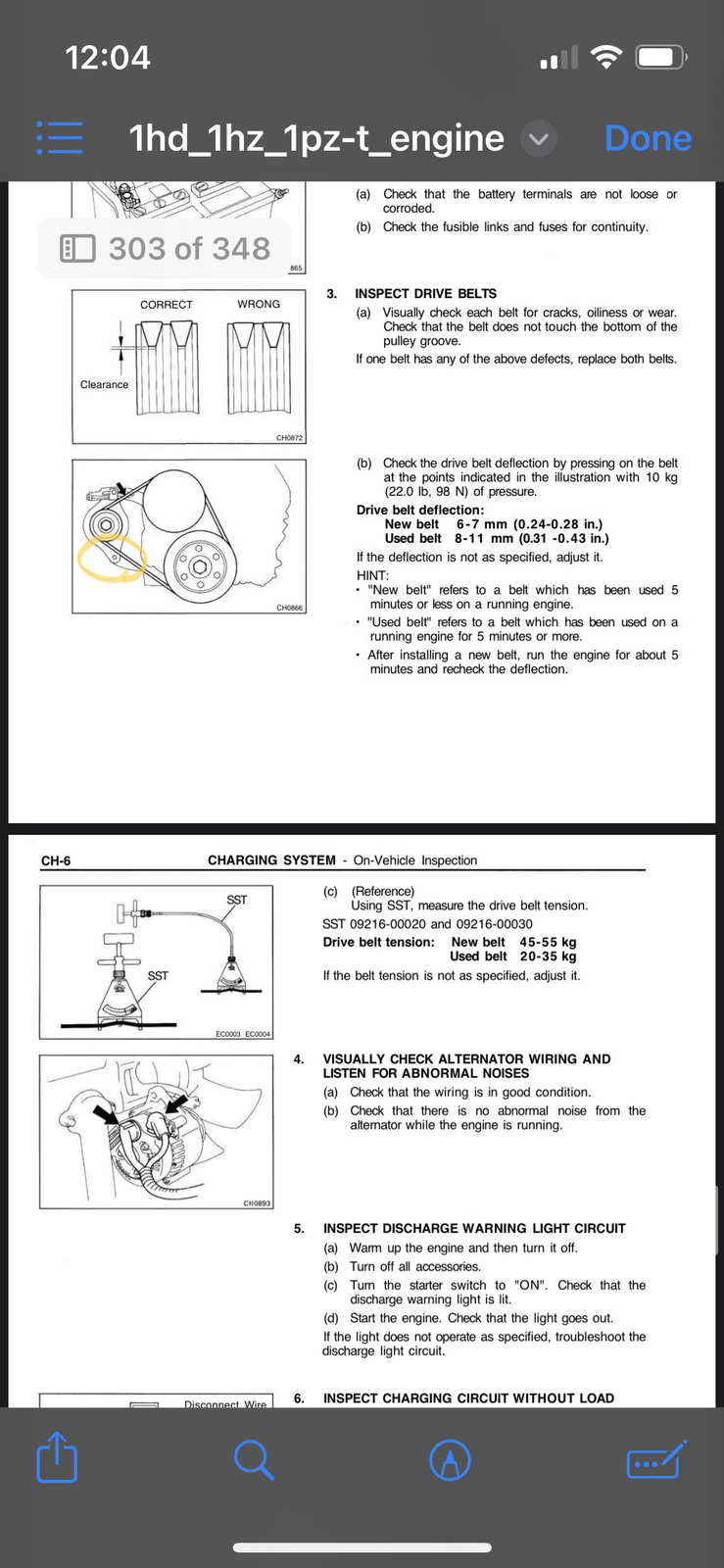

And without the SST drive belt deflection tool, what’s the best way to get the tension as close as possible to spec?

TIA.

Phil

I need to tighten the dual drive belts (alternator) but the process is too simple for anyone to have documented it for a fool.

The Toyota maintenance manual does nt even mention it. So as per the diagram - do first loosen the lower alternator nut (highlighted in yellow) then turn the horizontal adjustment bolt at the top?

And without the SST drive belt deflection tool, what’s the best way to get the tension as close as possible to spec?

TIA.

Phil