warrenpfo

Well-Known Member

- Joined

- Jul 21, 2010

- Messages

- 2,895

When do I need to use a relay to run led park lights and indicator light or is it only by trial and error and if your led lights are not working or flashing fast you then need to use one.

If no relay is needed what is the best way to T off my current headlight wiring to run the indicator and park lights in the ARB bumper. I had thought I would need to use some type of water proof connector but was told that it would be over kill and that 12v can handle the odd water crossing no problem.

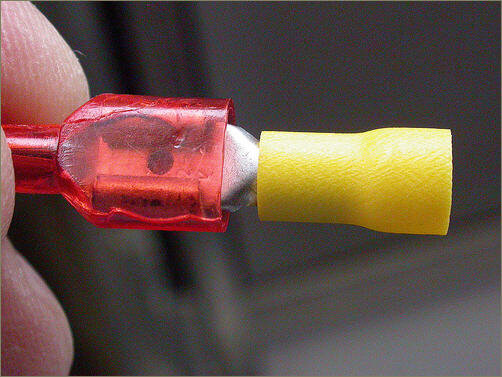

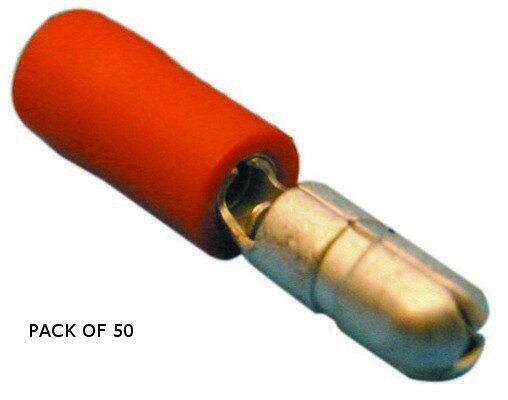

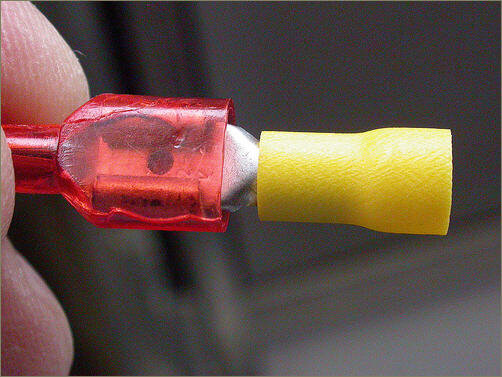

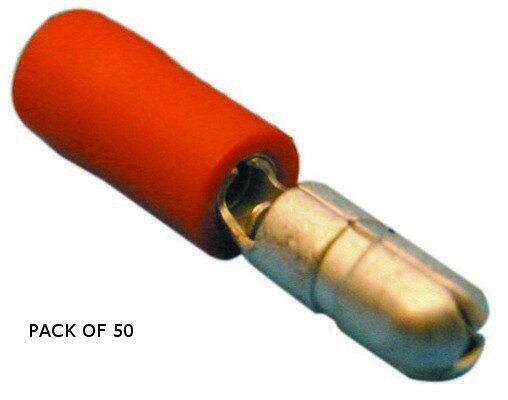

My thinking was either spade type connectors like these or the bullet type

with some tape over them but am not sure if its better to cut away some of the insulation on the current wire and then solder in the T and tape that up.

If no relay is needed what is the best way to T off my current headlight wiring to run the indicator and park lights in the ARB bumper. I had thought I would need to use some type of water proof connector but was told that it would be over kill and that 12v can handle the odd water crossing no problem.

My thinking was either spade type connectors like these or the bullet type

with some tape over them but am not sure if its better to cut away some of the insulation on the current wire and then solder in the T and tape that up.

Last edited: