I had a busy week at work.

I've been doing more work on the airboat.

This was going to be the donor vehicle.

The engine is just under 100bhp.

I worked out the height and position of the front 2 passenger seats.

Cut some alluminium.

And tek screwed it in position, it will be bolted on with M6 bolts into rivnuts at some point.

Fitted another one.

As we were going to use the Suzuki engine, we decided it would make sense to also use the Suzuki fuel tank.

Removed the tank.

It fitted quite nicely behind the bulkhead at the front of the boat.

We thought about fitting twin tanks to give us more fuel range.

The new folder bent a piece of 3mm alluminium beautifully!

Worked out the height this section needed to be welded on.

Got the TIG setup.

And tacked it in place.

We got lent a brand new boat seat by our local upholsterer/boat guy, so I could get some measurements for how big to make the frame that 2 of these seats will mount on to.

The frame of the seat is fiberglass.

A slight change of plan..........................

My boss has acquired a 250bhp Subaru Impreza engine that he wants to use instead of the 1.6l 100bhp Suzuki lump!

So with that I decided there was no point using the Suzuki fuel tank.

So I decided I would build a tank from scratch.

Cut a template of the shape/size of the tank.

Folded some 2.5mm thick alluminium.

Cut and folded up a baffle.

Welded it in place.

Thats as far as I got on the main body of the tank.

I found a low millage 2L Suzuki tank.

Removed the pump which has the fuel level sender and fuel flow outlet and return built neatly all into the one unit.

Next I started making the boss that the fuel pump unit will mount to.

I got a 15mm thick off cut from a piece of 150mm solid bar.

Cut the center out on the lathe using a hole saw.

It will need the mounting holes drilling and tapping into this alluminium boss, then it can be welded into the center of the top of the fuel tank.

I made a start on what will be my main job for the next week, making alluminium frames to mount the most efficient solar panels in for the solar Suzuki in preparation for next years attempt at the world record.

Started welding a frame up.

Out of channel.

Slid the flexy solar panels in.

Made up a frame out of 40mm tube for the first frame to mount inside of.

Welded in some corner braces.

And some tabs to bolt the other frame down with.

Bolted the other frame in position.

It weighed just under 24kg.

Trial fitting it on the roof of the car.

And finally the tip truck is now completely finished and ready to be put to work on the farm.

We had some stickers put on this week which I think finish it off nicely.

OK...........................

Finally LJ.

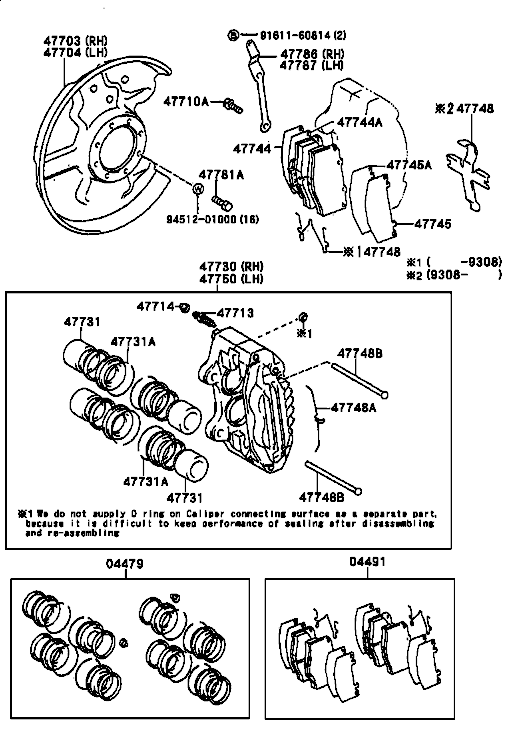

I finished fitting the passenger side brake caliper.

I had to grind a chunk out of the bottom of the caliper which I wasnt too happy about but I dont think it should matter.

Spaced it out with some washers to ensure the disc sat perfectly center in the caliper.

With that side done.

I moved on to the other side.

I decided to replace the brake hoses as after 23 years the rubber was a bit cracked and perished.

I was going to get stainless steel braided hoses made but I couldn't justify the price.

Fitted them.

And bled the brakes.

Aircon next.

The drier will be getting replaced as thats standard procedure when getting an old setup working again.

Removed it.

And the brackets.

Wire brushed it.

And rust killed the condenser surround and brackets.

Then painted it black.

And painted all the brackets.

Bolted all the brackets back on.

Started fitting it.

The space it would fit into.

The 2 metal power steering pipes would need moving and the horn and bonnet catch would need unbolting to allow me to swing the condenser in.

Power steering pipes disconected and twisted up out of the way.

And condenser in.

The brackets lined up with existing holes in the body and everything bolted up nice.

I re-fitted the front wheels.

And the wheels cleared the new bigger calipers nicely.

Back to the con install.

I needed to fit the pipe work next.

I'd fitted the power steering pipes in front of the radiator years ago when I did the engine conversion but I really wasnt happy with their position, they were in the way and looked shit.

I removed the pipes.

I managed to run them neatly along the front cross member instead, behind the winch, in a much better position.

I took LJ to work on Friday and after work I de-greased and steam cleaned the engine and underneath.

I have a confession that I did something really really stupid and that was why I needed to steam clean the engine.

After bleeding the new brakes, I thought I will just drive backwards and forwards a few times and test the brakes. Only issue was the power steering pipes were not connected and were sat up in the air.

So I ended up with a power steering fluid fountain that went f*****g every where!

Anyway..............

After cleaning LJ I got her on the hoist for a full check over and to try and diagnose an engine oil leak.

There were no noticeable leaks with LJ on the hoist with the engine running but I believe I've traced it to the top of the engine on the turbo intake pipe, so I will order a new gasket.

I went out and saw the guys at Huntsman on Saturday for a replacement KM2 tyre to replace the damaged one.

They gave me an absolutely awesome price and wearing my Piranha shirt helped as they know my boss and come in from time to time for Suzuki parts.

New tyre fitted on my rim.

Old tyre which I have a seriously cool use for.

While fitting the new tyre the guy shouts over to me from the tyre machine "I've found what caused your puncture"!

He had found a massive chunk of hardwood inside the tyre!

Removed my spare which is a KM1, purchased from Tony Toyota many years ago, and fitted the new tyre.

Still cant get over that chunk of wood! Crazy!

I also picked up a drop hitch as I'm going to add a receiver hitch to LJ's rear bumper.

As its going to probably be a few years until we can afford a 79 series ute, we will instead buy a big trailer for the property renovations were planning on getting into next year when we buy the first property to fix up and sell on. So LJ will become chief tow vehicle to enable us to pick up materials and drop off rubbish at the tip.

I also got a sticker from them for my tool box.

Bec is on nights this week meaning I should get plenty of time each evening to get lots done on LJ.

The grill needs to come back off so I can finish a little bit of wiring and fit the support/securing brackets to the aircon pipes.

I need to source the mounting brackets to mount the air compressor onto the 1KZ-T(E) engine as that is one thing the guys at All 4x4 dont have.

Looking at pics of 1KZ-T aircon compressors I suspect I may need to make/source some pipes to connect the new pump to the rest of my system as I dont believe the ends I've currently got fitted will bolt to the 1KZ-T pump.

I also need to finish wiring and plumbing up the fuel transfer pump.

Modify my rear bumper to add a receiver hitch for towing.

Once all thats done I want to turn my attention to the rear end regarding the disc brake conversion and 3 link suspension conversion.

I also need to fit a modified quick release anti roll bar.

So making progress, but lots still to do.