Chris I wasn't suggesting it would be, just that it was possible to fit a ladder to a tailgate other than a barn door type as mentioned by Clive who's post I was commenting on and that it might also be of interest to others who want a fixed ladder.Chas, I have a RTT not a pop up so rear ladder utterly useless for me.

Don't like the adverts? Click here to remove them

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Project 80: Codename Grey Ghost

- Thread starter Chris

- Start date

Cheers Gary. Got your text.

Been on a bit of a road trip. I shall be posting later this week. Went up around Dumfries and Galloway and down through the lakes. Truck was great but suffering with the suspension which needs more oomph. Oz tent was ace again. The Oz stretcher bed was phenomenal. Anyway more to come.

Been on a bit of a road trip. I shall be posting later this week. Went up around Dumfries and Galloway and down through the lakes. Truck was great but suffering with the suspension which needs more oomph. Oz tent was ace again. The Oz stretcher bed was phenomenal. Anyway more to come.

Chris I wasn't suggesting it would be, just that it was possible to fit a ladder to a tailgate other than a barn door type as mentioned by Clive who's post I was commenting on and that it might also be of interest to others who want a fixed ladder.

Finally got the photo to upload, sorry it's late, and, irrelevant to boot...

Actually not irelephant at all actually Clive. I have ordered a pop top hard shell tent and will be looking at putting a ladder up the back to use the rear door of the tent. Might buy one, but might make one too so all ideas welcome.

Gary820

Well-Known Member

Cheers Gary. Got your text.

Been on a bit of a road trip. I shall be posting later this week. Went up around Dumfries and Galloway and down through the lakes. Truck was great but suffering with the suspension which needs more oomph. Oz tent was ace again. The Oz stretcher bed was phenomenal. Anyway more to come.

I was gonna flash but waste of time in the beemer lol.

suspension not coping with the weight?

Don't like the adverts? Click here to remove them

No it's not, but then it was never supposed to Gary. It wouldn't be on the IM set up now if a certain individual got their finger out and ordered me the set up I asked for at the start of the year. I like the feel of the Ironman B set up. For a standard 80 owner who's looking for an upgrade to old std springs, it's perfect. I may sell it on. I don't think I can fault it other then the shit finish. But I had mine blasted and re coated

Actually not irelephant at all actually Clive. I have ordered a pop top hard shell tent and will be looking at putting a ladder up the back to use the rear door of the tent. Might buy one, but might make one too so all ideas welcome.

This is nice to know! I don't think it was easy to make. The guy tried too hard, but I got a good job as a consequence. He wanted to follow the truck profile on the left (sloping inward at the top) and the door profile on the right (vertical), all his idea. I asked him to ensure good clearance between the ladder and the back door, as I didn't want toe dents in the door. It works well, especially when boots are laden with snow or mud. The rungs are square hollow section steel, with chequer plate treads. The stringers are steel tube and it's all welded. The tube ends are bent to save "sharp" tube ends, which is more useful than I ever imagined. It's very nice to handle and the wider bottom rungs are a boon when reaching sideways tying down onto the rack, no treading on your own feet either.

The strings go well above the top rung, which makes it quite a lot safer IMO. It's hooked on at the top and bolted at the bottom, which is a mistake. The top should have been bolted somehow. I have to change that one day, otherwise it's great. Finished in hard-gloss oven baked paint, there's no chips or scratches after 18 months, and I use it. Great for the ski bag on the roof in winter, lugging stuff all year round, luggage, wheels and tyres, furniture, you name it.

What hardshell pop-top will you get Chris? I want one but I don't think the rack is suitable. Sod's law that I bought the rack in ignorance of RTT fitment. I'm wondering if I can adapt it for use with an Airtop or ideally a James Baroud. Getting one is my problem, I need someone to special order it for me here, or drive to another country to go shopping!

Last edited:

Well, new suspension on the way. Given the total ineptitude of UK suppliers, I have some being shipped from Oz by Chris Blakemore at FNB. Full EFS set up with a 4" lift rated to take all my kit. Absolute pleasure to deal with. UK suppliers should be hanging their heads in shame frankly.

In anticipation of this, I started making the adjustable panhard rods. Yes yes I could buy them but given the cost and frankly what little they need to do, I figured I'd save a heap. Follow me into the man cave ..

Did make a start the other weekend but scrapped that lot and started again today.

Chopped a spare PH rod in the saw. Measured up around 26 mm.

It's seamed tube so I needed to bore that out to make it lovely and smooth ready for threading.

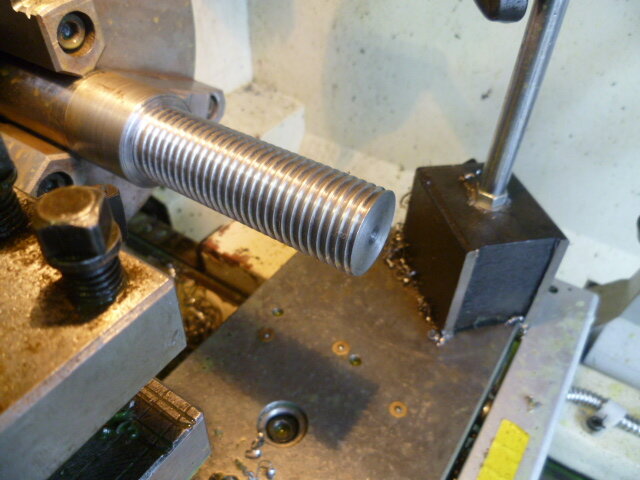

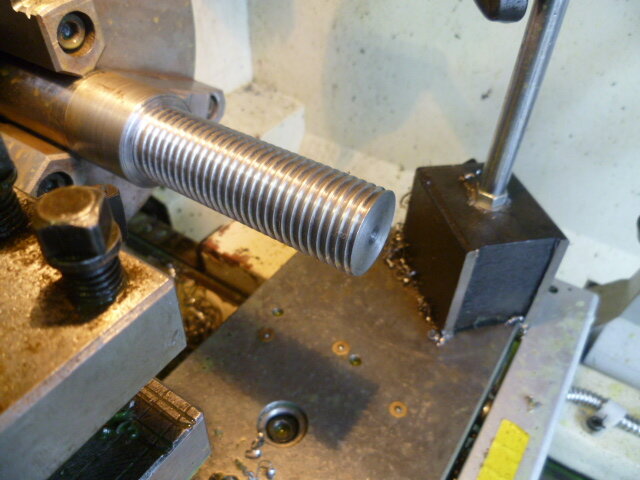

I threaded the RH tube first. 26mm 3.0 pitch. I measured it before cutting so that the short end would go through the chuck from the head end of the lathe, and used a fixed steady to prevent deflection whilst cutting.

Then I cut the bottle screw for the short end

Pretty simple. 3.0 is a bit of an ugly thread though. 2.5 or 2.75 might have been better.

Threading the inside of the long half (?) was easy enough. But setting up to cut the left hand thread on the bottle screw took a little fiddling.

Both ends threaded. Just need to add a little finesse to the central section on the miller so I can turn it with a BF spanner.

It all screwed together very well indeed. I took the lazy option to start cleaning the arm up in the lathe whilst I was about it.

Amazingly when I popped it in the lathe and measured the run out I got a total of 3 thou. Holy crap. That'll do for me.

Engagement of the threads at each end is 85mm. I think that given the typical extension following a lift is only about 1/2 an inch, this will be plenty. I may actually have to short the arm once I get the springs on. I may have made it too long to kick off with. But that's a five minute job. I cut a piece out of the arm to begin with to allow for the central section of the screw.

I then made up a couple of 26mm left and right locking nuts. Once locked off there is no detectable wobble or anything in the rod. I figure it's job, jobbed. The front one next. I shall over-sleeve that I think as it's solid.

So there we go.

In anticipation of this, I started making the adjustable panhard rods. Yes yes I could buy them but given the cost and frankly what little they need to do, I figured I'd save a heap. Follow me into the man cave ..

Did make a start the other weekend but scrapped that lot and started again today.

Chopped a spare PH rod in the saw. Measured up around 26 mm.

It's seamed tube so I needed to bore that out to make it lovely and smooth ready for threading.

I threaded the RH tube first. 26mm 3.0 pitch. I measured it before cutting so that the short end would go through the chuck from the head end of the lathe, and used a fixed steady to prevent deflection whilst cutting.

Then I cut the bottle screw for the short end

Pretty simple. 3.0 is a bit of an ugly thread though. 2.5 or 2.75 might have been better.

Threading the inside of the long half (?) was easy enough. But setting up to cut the left hand thread on the bottle screw took a little fiddling.

Both ends threaded. Just need to add a little finesse to the central section on the miller so I can turn it with a BF spanner.

It all screwed together very well indeed. I took the lazy option to start cleaning the arm up in the lathe whilst I was about it.

Amazingly when I popped it in the lathe and measured the run out I got a total of 3 thou. Holy crap. That'll do for me.

Engagement of the threads at each end is 85mm. I think that given the typical extension following a lift is only about 1/2 an inch, this will be plenty. I may actually have to short the arm once I get the springs on. I may have made it too long to kick off with. But that's a five minute job. I cut a piece out of the arm to begin with to allow for the central section of the screw.

I then made up a couple of 26mm left and right locking nuts. Once locked off there is no detectable wobble or anything in the rod. I figure it's job, jobbed. The front one next. I shall over-sleeve that I think as it's solid.

So there we go.

Very neat CJ as we have become occustomed,

My rear axle is about 1/2" out at rest, varying around that I suppose on flex.

Without your lovely lathe, I'm kinda resigned to it, the price of a pair of adjustables is well beyond any benefit gained.

I was thinking of some sort of tab washer lock, which might be an alternative, should the locknuts come loose. It's doubtful though, there's no vibrations there, it can all rust up solid once you've got the adjustment set!

My rear axle is about 1/2" out at rest, varying around that I suppose on flex.

Without your lovely lathe, I'm kinda resigned to it, the price of a pair of adjustables is well beyond any benefit gained.

I was thinking of some sort of tab washer lock, which might be an alternative, should the locknuts come loose. It's doubtful though, there's no vibrations there, it can all rust up solid once you've got the adjustment set!

Didn't actually measure it Ben. I will find the off cut and size it. It was pretty thick as you can see in one of the first pictures. At least 3mm. Maybe 4. Obviously I cut into the wall to thread it, but making the engagement 85mm either end, I don't think it will be a weak point. I also put the joint 2/3 along the length rather than in the middle. With nice new bushes in the eyes, it should all be quite happy.

Look what I just found. I think mine is better though

http://www.ebay.co.uk/itm/Toyota-La...=AU_Car_Parts_Accessories&hash=item1e94d58d29

http://www.ebay.co.uk/itm/Toyota-La...=AU_Car_Parts_Accessories&hash=item1e94d58d29

Hmm, not really mate. It looks easy doesn't it. But that's a whole Sunday in the workshop. A factory could churn those out in minutes I'd bet.

Now, making only one adjuster would be a lot easier. So, like the Ironman one, you have to take one end out of the mount and twist it til it's the right length. That would be simpler. As it's a right hand thread you could even buy a bolt and cut the head off, machine it down and shove it into the tube, weld it, then thread the other half to match the bolt. Order a nut with it too so you have the locking device.

Significantly less work. I wanted one with a bottle screw so that I can adjust the body position in situ. It just makes life easier especially when you work on your own.

That might be possible.

Now, making only one adjuster would be a lot easier. So, like the Ironman one, you have to take one end out of the mount and twist it til it's the right length. That would be simpler. As it's a right hand thread you could even buy a bolt and cut the head off, machine it down and shove it into the tube, weld it, then thread the other half to match the bolt. Order a nut with it too so you have the locking device.

Significantly less work. I wanted one with a bottle screw so that I can adjust the body position in situ. It just makes life easier especially when you work on your own.

That might be possible.

stumog

Well-Known Member

- Joined

- Oct 3, 2012

- Messages

- 3,793

- Country Flag

Hmm, not really mate. It looks easy doesn't it. But that's a whole Sunday in the workshop. A factory could churn those out in minutes I'd bet.

.

But the more you do the faster you get.

Similar threads

- Replies

- 30

- Views

- 2K