Garfieldus

Well-Known Member

- Joined

- Nov 18, 2010

- Messages

- 361

- Country Flag

......of no power at the rear diff lock?

Mine stopped working a few weeks ago and I assumed it would need the usual removal and clean up and hopefully get it working again.

Got at it today and wanted to make sure there is power to it before taking it off so....

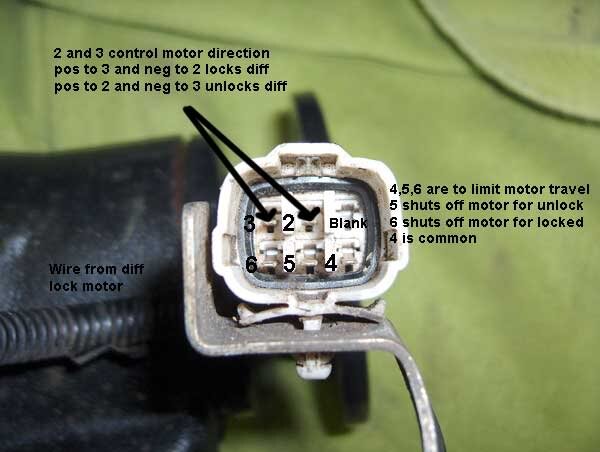

took off the stone guard, disconnected the power connector and put a (working ) test lamp on pins 2 and 3 (loom side). Turned on ignition, moved to low range (centre lock and ABS lights on), turned locker switch to rear position but the test lamp didn't light.

) test lamp on pins 2 and 3 (loom side). Turned on ignition, moved to low range (centre lock and ABS lights on), turned locker switch to rear position but the test lamp didn't light.

So, no power seems to be the cause.

30amp DIFF fuse is ok (front locker works and engages).

Any advice on where to start looking?

Mine stopped working a few weeks ago and I assumed it would need the usual removal and clean up and hopefully get it working again.

Got at it today and wanted to make sure there is power to it before taking it off so....

took off the stone guard, disconnected the power connector and put a (working

So, no power seems to be the cause.

30amp DIFF fuse is ok (front locker works and engages).

Any advice on where to start looking?