I finished my work on the trailer build this week.

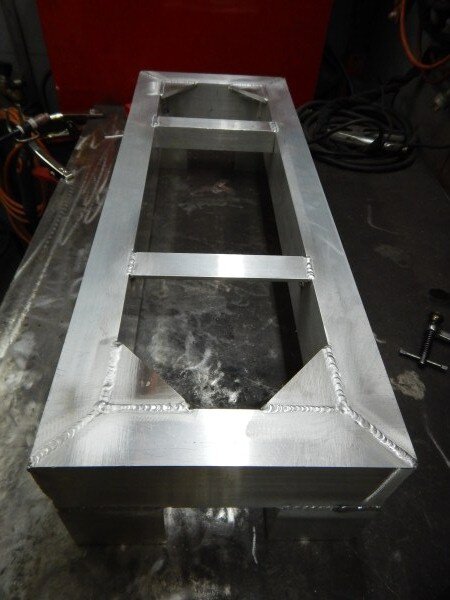

Mounted the 2 alluminium boxes I made.

The one side will have a 10" Optima in it for the winch.

The other side will carry ratchet straps and the fair lead for the concealed winch.

The winch has been wired up now.

And with the door shut and section of floor back in place the winch is completely hidden.

I needed to re-mount the spare wheel.

So I made a bracket for it.

With it tack welded in position I could test fit the wheel.

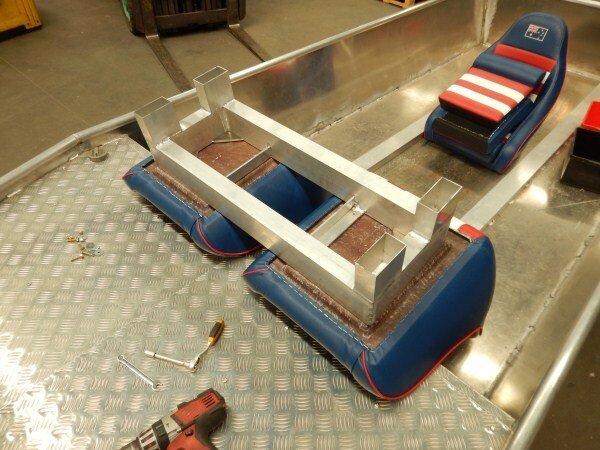

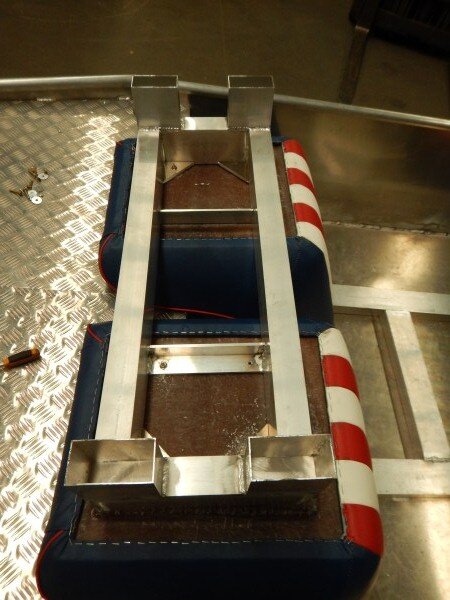

Ramps next.

Cut the ends to the correct angles.

Marked where all the pieces of angle would go.

I could then weld all the pieces of angle in position.

I welded a length of thick 25mm angle along the back of the trailer.

I could then work out how best to hook the ramps on.

I picked up some really thick alluminium angle to cut down and weld to the ramps.

Clamped and tacked a piece on.

Tested it.

Then fully welded it on.

I trimmed the other end of the ramps to allow me to fit some 6mm checker plate.

I folded up a piece of 3mm checker plate to fit inside the box under the tray, to separate the winch and the ramps.

Tested the ramps.

Ive got to make a big gate for the side of my bosses house.

The opening between the side of the house and neighbors house isnt square.

Because the opening isnt square I wanted adjustable hinges, but for some reason none of our local suppliers had any adjustable hinges, or had ever seen them before. Something I would have sourced very easily in the UK.

So I decided I would have to design and make my own.

The parts.

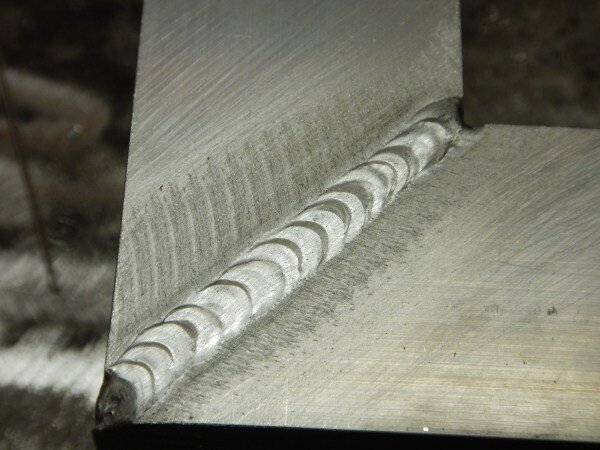

TIG welded them together.

Drilled the frame for the gate and welded them in position.

Next week I will be away at the farm working on the tree house all week so I've been busy getting materials ready for that.

One thing I needed was 2 gallows brackets to help support the roof over the firemans pole.

I decided to make them a bit quirky I would make them out of pieces of High lift jack as weve got lots of bits of them at work, as High Lift in the USA used to ship them in crates made of sections of high lift.

Started by cutting 2 pieces to length with 45 degree cuts.

One of the pieces was punched wrong, I'm guessing thats why it ended up as scrap.

Found some plates that I could weld onto the ends.

Welded them on and then hung them up for a coat of black paint.

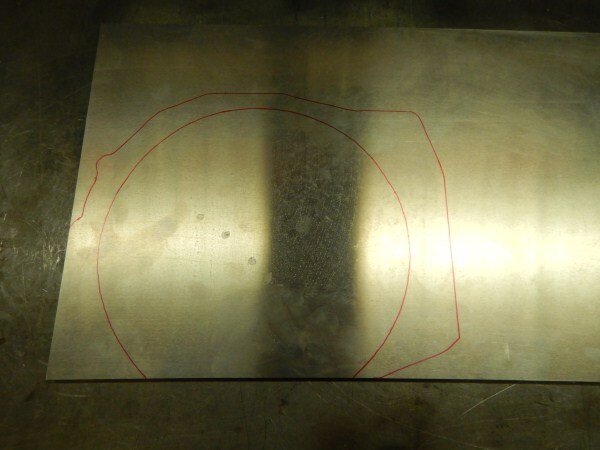

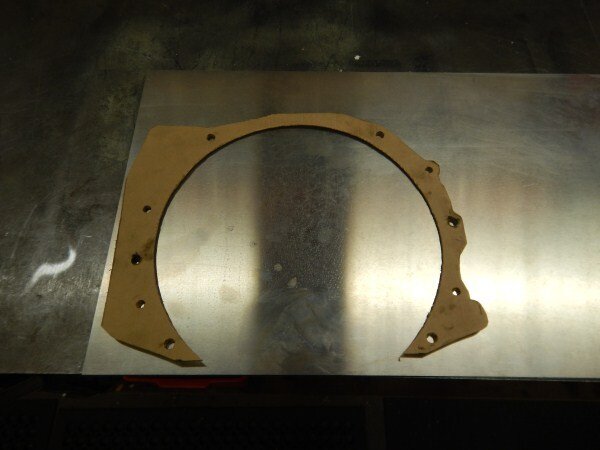

The week before last my mate Brady (who had the white 60 series and cute black labrador) turned up at my work in one of his stunning cars, so I could measure up to make some covers for his engine bay.

Next to the huge 6 litre V8 he had 2 items he wanted covers making for.

He wanted the brake pipes/ABS covering up.

And on the other side an electrical component.

Cut and folded some 1.2mm alluminium.

Welded.

Test fitting.

They will need a slight trim around the brake pipes and electrical wiring to make them both sit down a bit. Then Brady will get them painted the same colour as the car.

OK.......................

Finally back to LJ.

So last weekend I did a bit more work on putting LJ back together after I had done the painting.

The areas I filled have come up great.

The paintwork is a bit orange pealy in places so I might cut and polish it all in about a month once the paint has fully hardened and dried.

Some parts I ordered a few months ago finally turned up!

A replacement glovebox lid and an aircon pump mounting bracket.

Sadly the anti roll bar/swaybar bracket I also requested wasnt in the box though, so I still cant re-fit an ARB.

Stripped and cleaned the aircon pump bracket.

The bearing felt ok but decided for the sake of $3 I would change it.

Re-assembled it.

The empty space for it on the side of my 1KZ-T engine.

Bolted it on.

Was hoping to have the new aircon pump fitted and the whole system gassed up and working in time for the huge road trip up to the new house, but because of the ridicolous amount of time it took for the mounting bracket to reach me, its not looking like I will have time now.

When I removed LJ's grill for the paintwork I spotted the drivers side headlight had been hit by a stone and was broken.

I had the original lights that I had to change when I got LJ on the road here, as the enginear wrongly thought the head lights were rusty. It wasnt rust it was Lincomb sand!

So I soaked one in the sink with some hot water and soap.

And managed to get all the sand cleaned out.

Re-fitted the roof rack.

And put LJ to work!

One of the big bed shops here had an upsize sale on where by you could buy any size matress for the price of a single.

So we bought a top of the range king size one for the price of a single, a huge saving!

Once weve moved into our new house one of my first projects in my new garage will be to design and build us a bed for it out of Tasmanian oak.

So a full week at the farm next week to hopefully get the tree house finished!

Then 3 days at Piranha then were done and can hit the road and start the big move!

Cant wait!!