OK..........

Time for an update.

Work is progressing well on the 78 and I'm on track to hit my target of rear door finished and interior back in by the end of the week.

Rear Door First.

It was quite badly dented.

Using my cheap body work set.

I managed to knock most of the bottom dent out.

But I couldnt get anything up inside far enough to get the top dent out.

So then I started thinking and I decided really what I needed was a proper stud welder, dent puller where you weld studs on and pull the dent out.

But their not cheap and its not something I'd use very often and besides I already have a top of the range TIG/ARC and a reasonably good little MIG.

So then I did some research into using one of the welders I already have and found this from the states.

And I thought I could make that and its only going to cost me a few bits of scrap metal I already had and $13 for a cheap hand drill from Bunnings.

Picked up a cheap $13 hand drill.

All I actually wanted was the chuck for my slide hammer, but I will keep the rest as I have plans to use a mechanism like that on a small wind turbine I want to build one day.

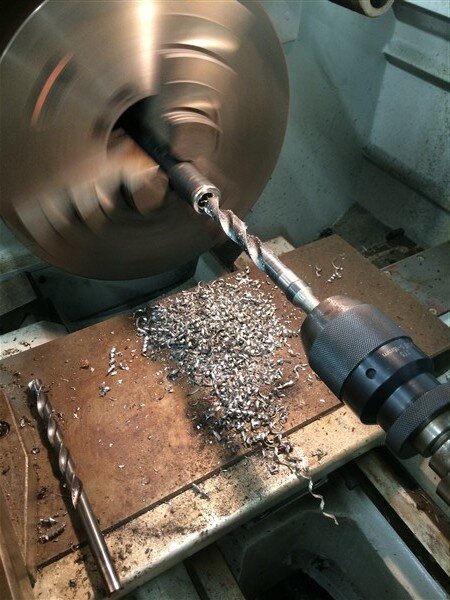

I took a piece of 25mm round bar to work and cut it to length, this was to be the handle on the slide hammer.

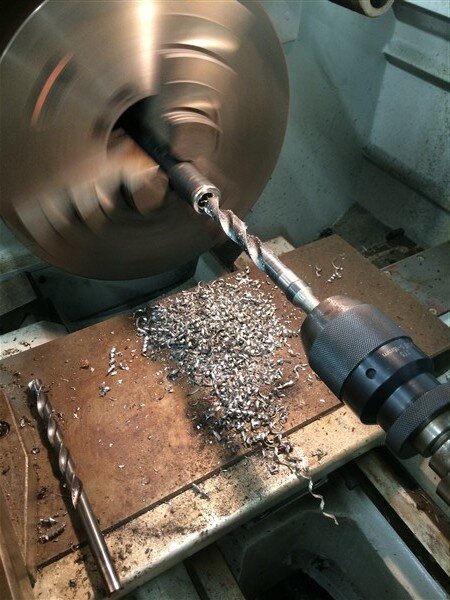

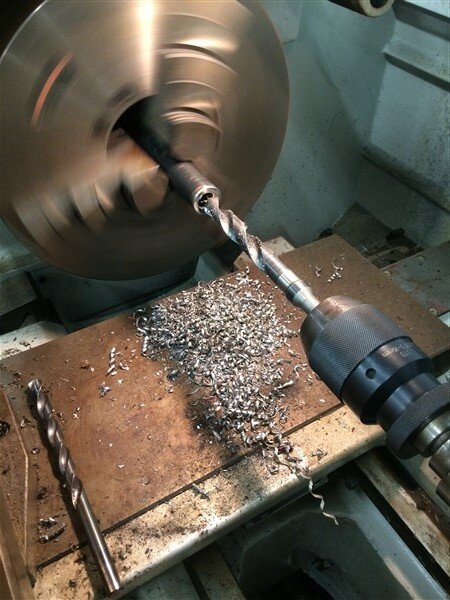

I then put it on the beast of a lathe.

Put a 12mm drill bit through it.

Followed by a 16mm one.

It looked good on one end.

But the other end was totally wrong.

That went in the scrap bin and I found a piece of steam pipe, left over from when I sleeved the steering bar on this 78 build.

Dug out some nice big hole saw waste pieces from my washers box, all 5mm thick.

Drilled the center holes bigger in the drill press.

Removed the threaded section from the drill that the chuck screws onto.

Cut it down slightly.

Then I cut some 16mm round bar to length and then I had all the parts for the slide hammer.

Decided to take the 16mm bar to work and put it in the lathe so I could drill a nice 7.5mm hole in the end for the chuck threaded section to sit in.

Then the TIG welding could begin!

Few tacks first.

Then fully welded.

All welded and ready to assemble.

Next I needed to make the stud attachment for the MIG.

Found some scrap stainless tube the correct diameter to fit over the end of the MIG torch.

Cut it off and found some brake tube and cut that to length too.

Welded them together.

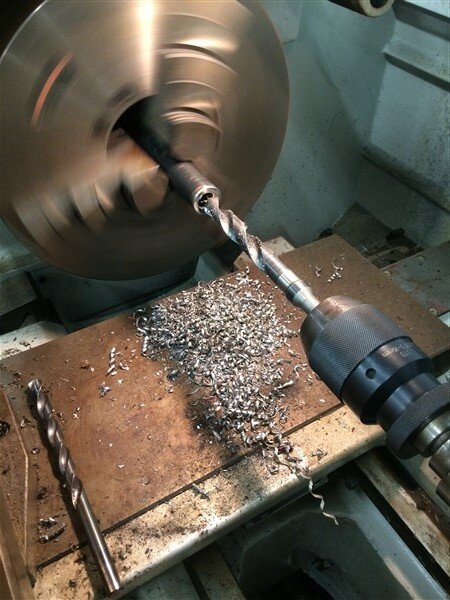

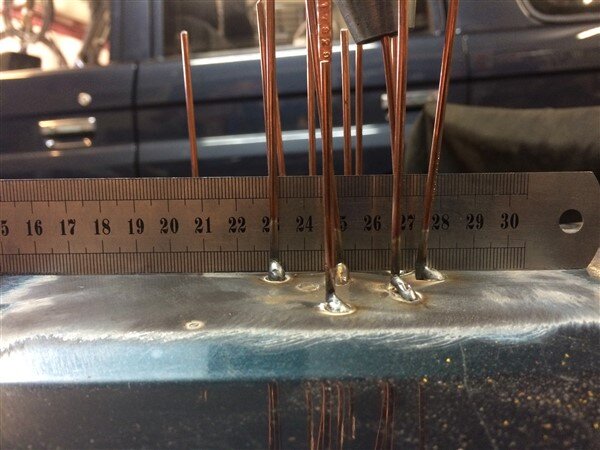

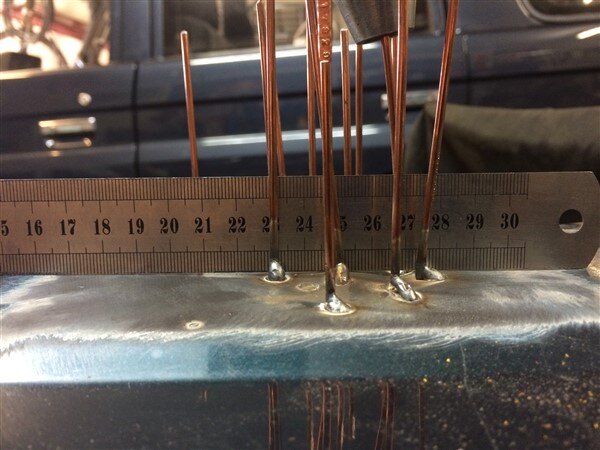

Cut a 2.4mm TIG filler rod into pieces to use as my studs.

And I was ready!

Cost me $13 and about 2 hours of my time.

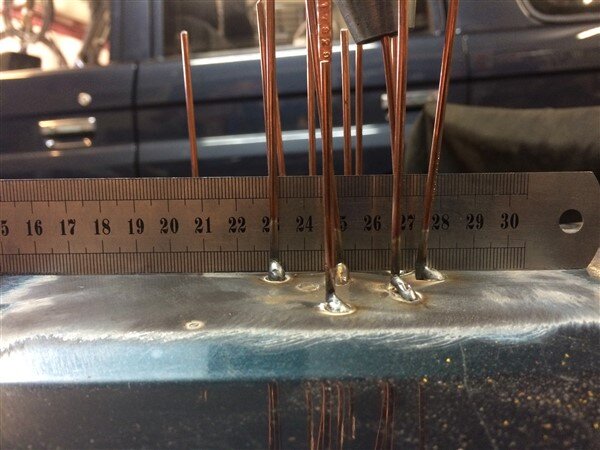

Cleaned the paint off the door.

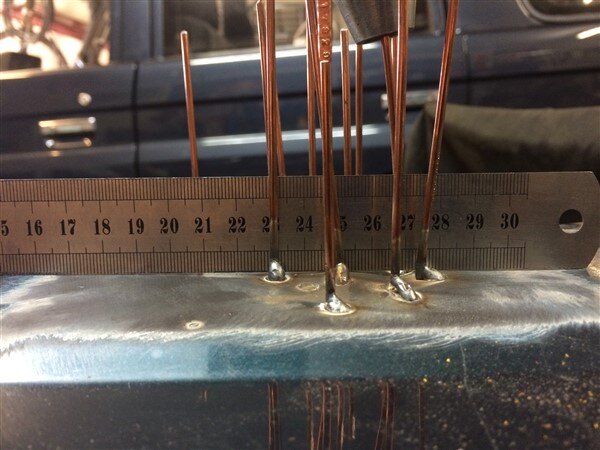

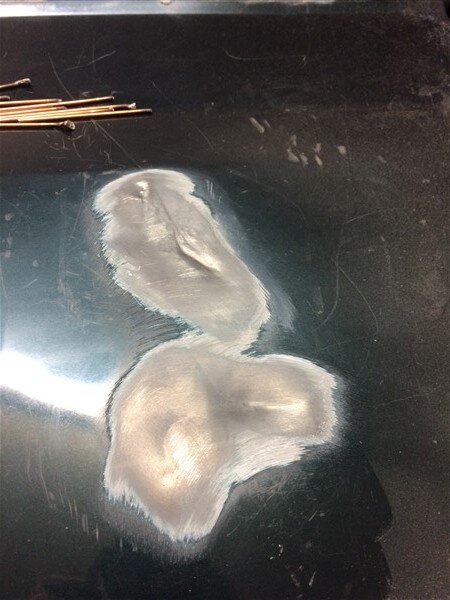

Welded the studs on.

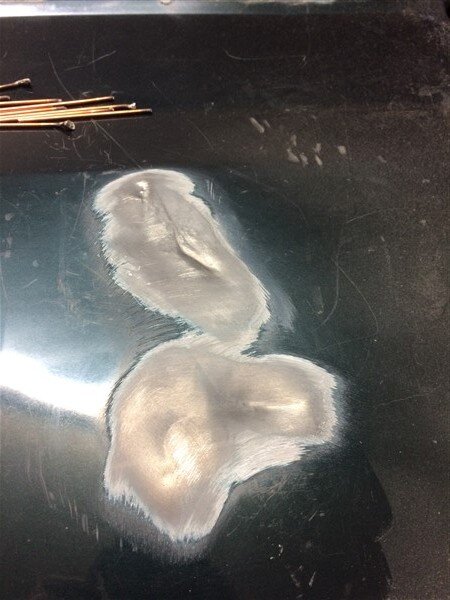

Put the slide hammer on and started pulling the dent out.

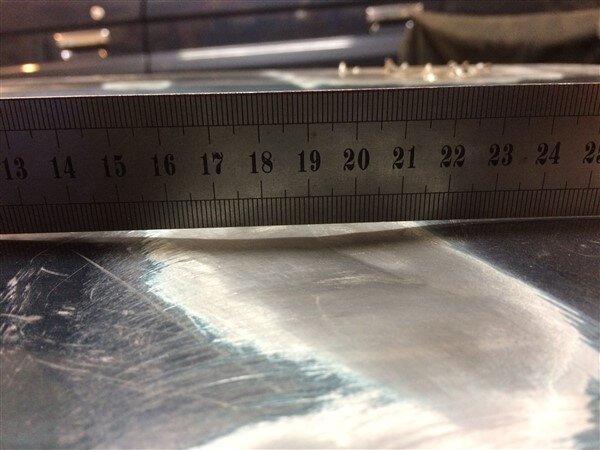

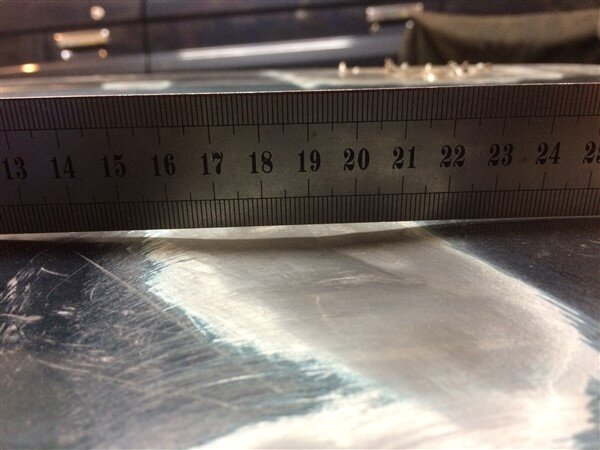

I should have taken some before pics as it was 10-12mm dented in to start with.

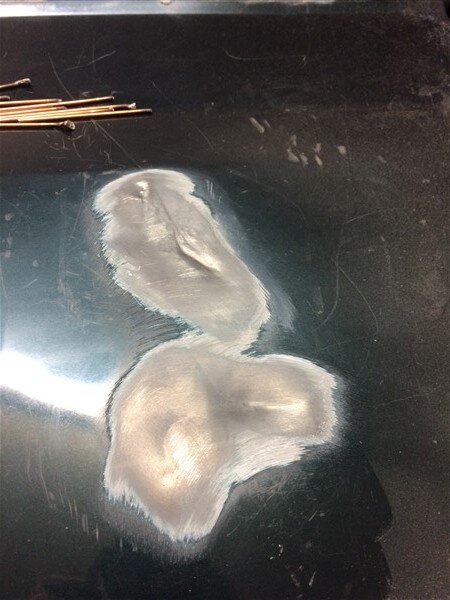

And afterwards.

As it had worked so well and was so quick and easy I decided to do the other dent.

Cleaned the paint off.

Few before pics.

More stud welding and slide hammering.

And I was very pleased with the results!

I then got the door outside and cleaned it all up and smoothed the welds down.

Gave all the bare metal a few coats of etch primer.

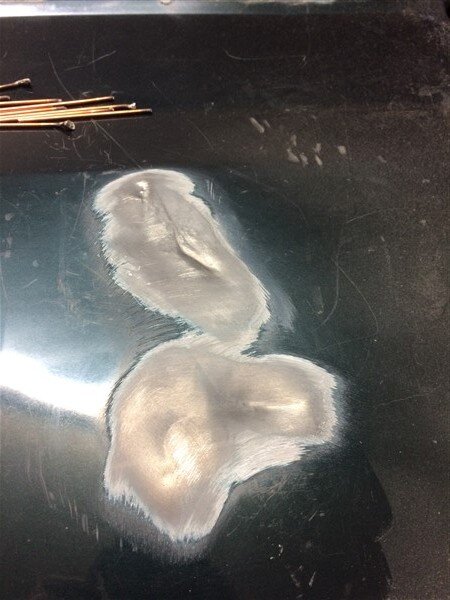

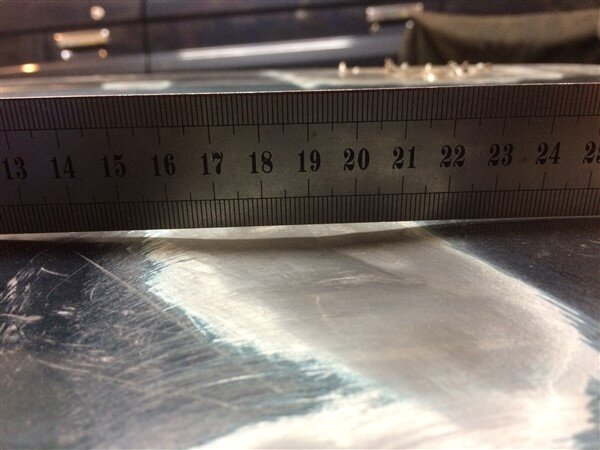

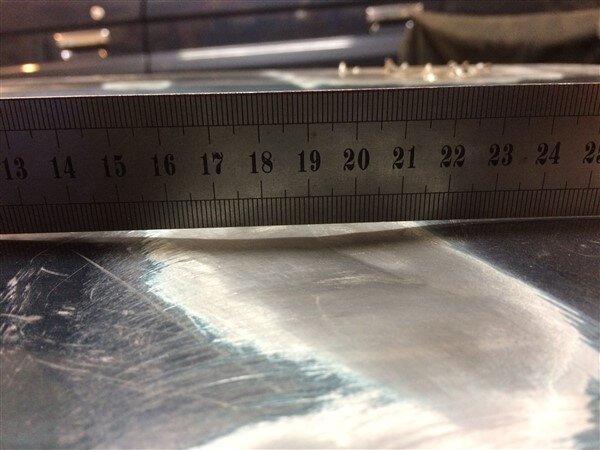

Followed by a 0.5-1mm skim of filler.

Once that was sanded it got another coat of primer.

Then it was ready to drop off at the panel shop.

The guy reckons it should be ready by the middle of next week.

I did a tiny bit in the engine bay.

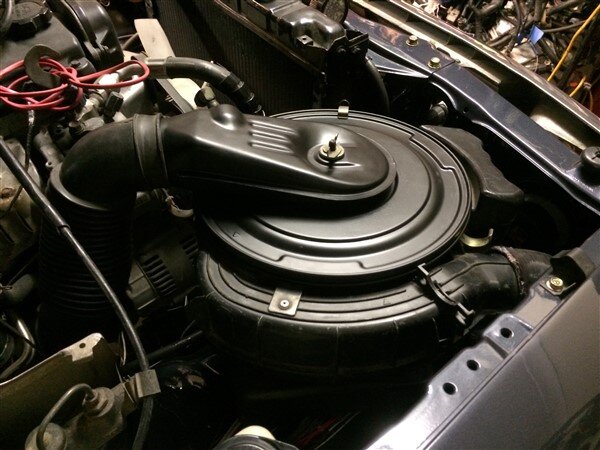

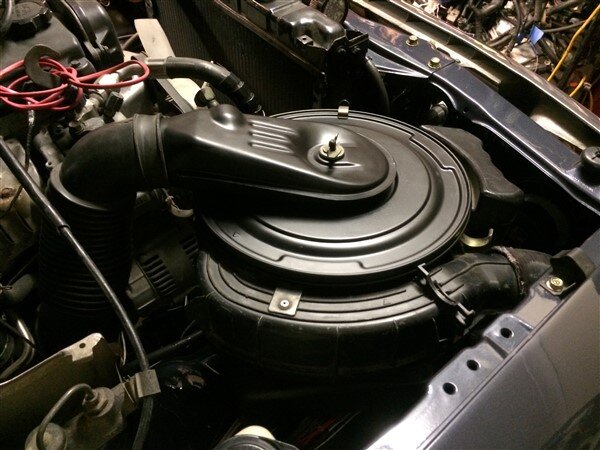

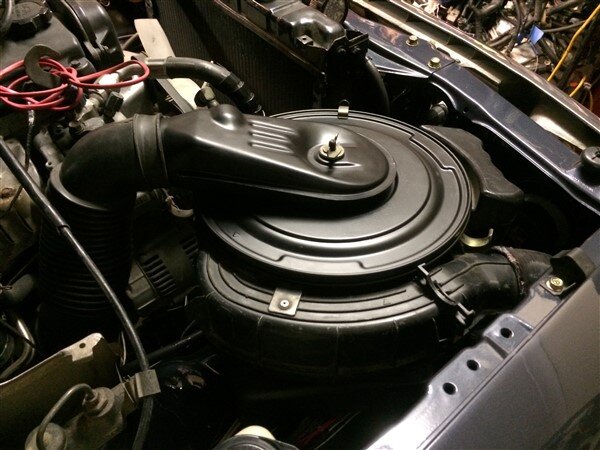

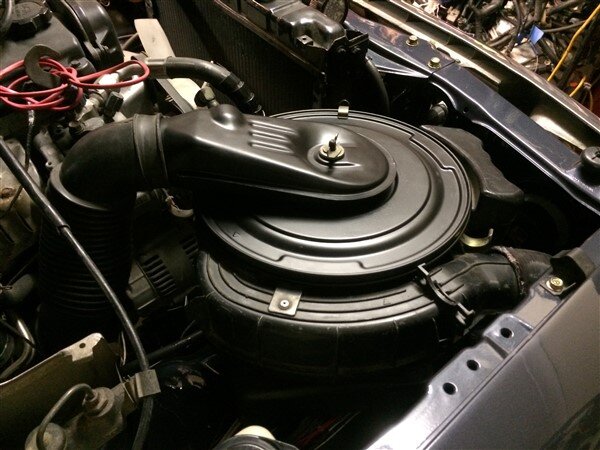

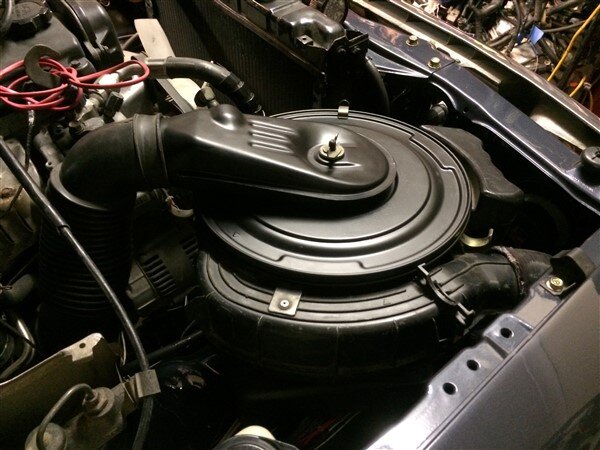

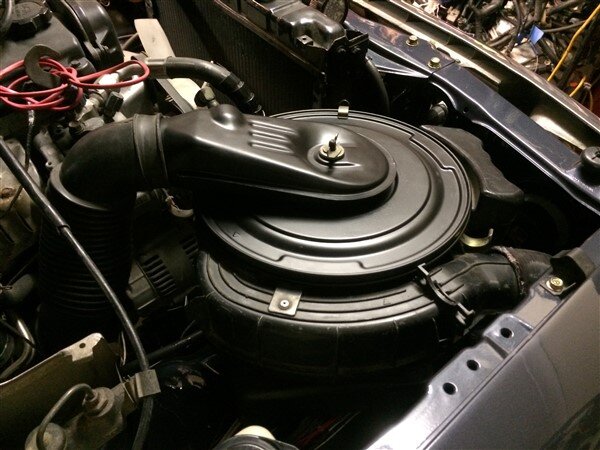

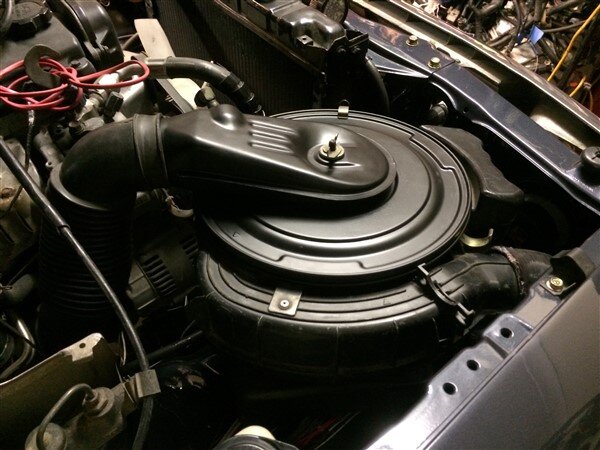

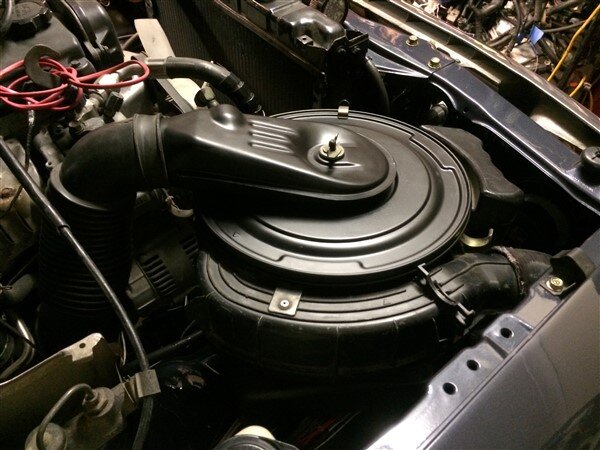

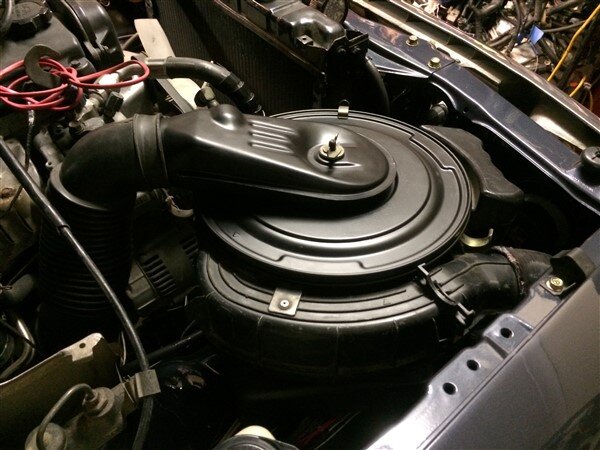

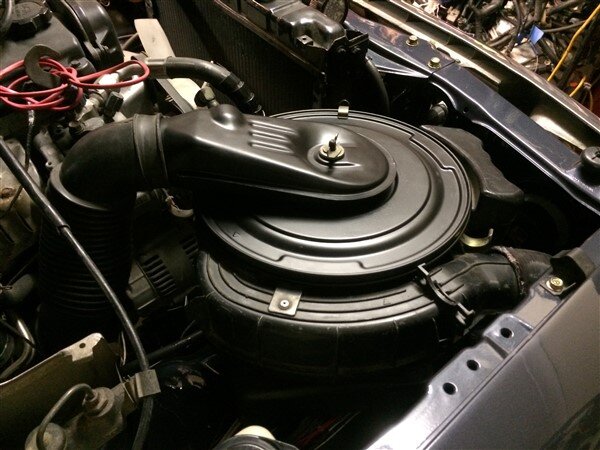

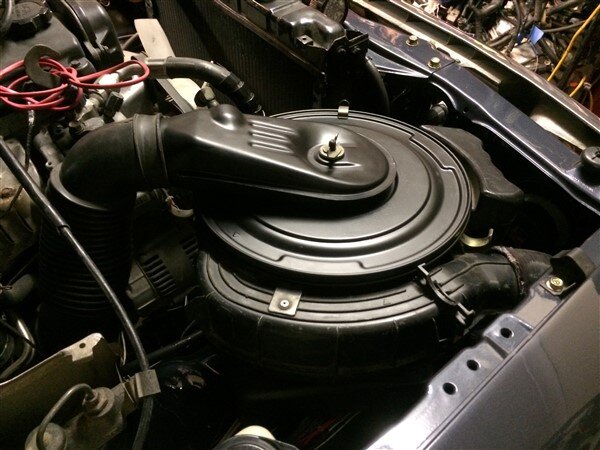

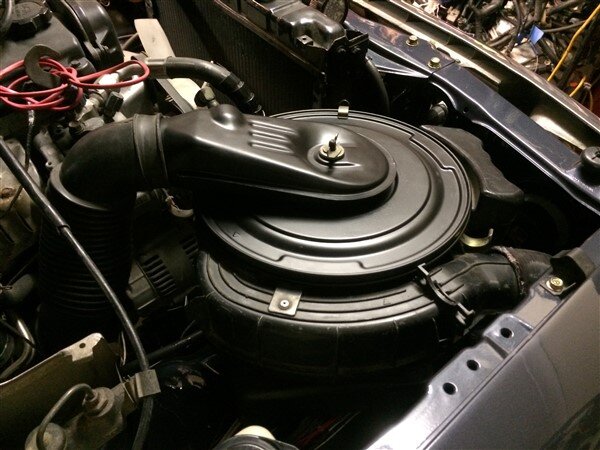

Fitted my silicon bend to connect my snorkel to the airbox.

The original one that came with the snorkel was very restrictive.

Was quite tight getting it through the guard and onto the snorkel and I resorted to giving the inside of it a coat of wd40 to help get it onto the snorkel.

Then it was ready to connect to the airbox.

Airbox only just fits.

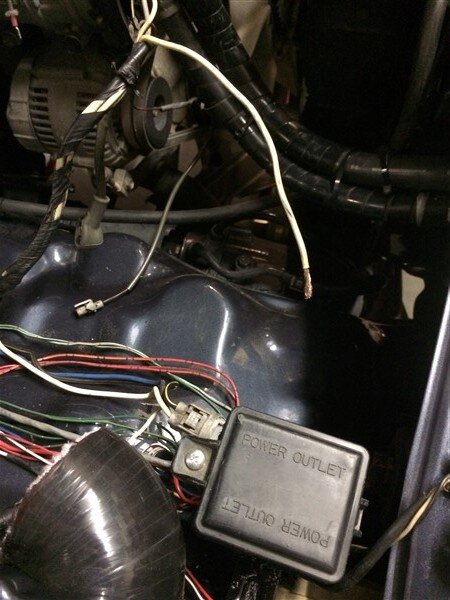

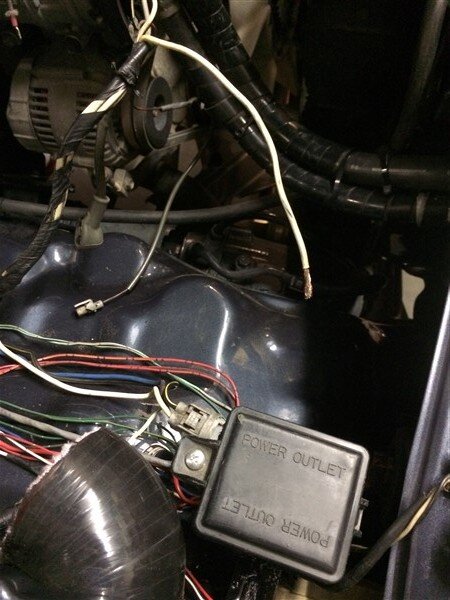

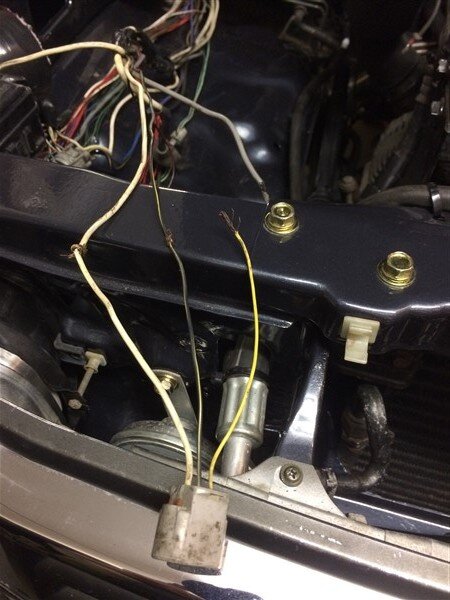

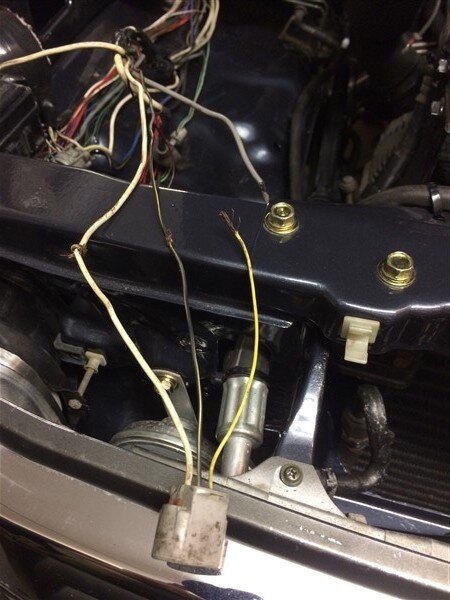

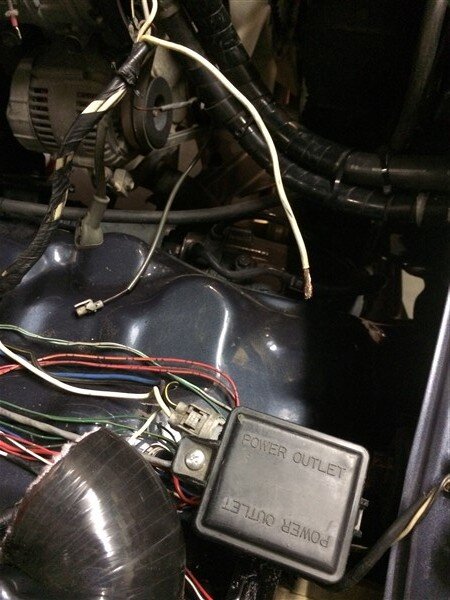

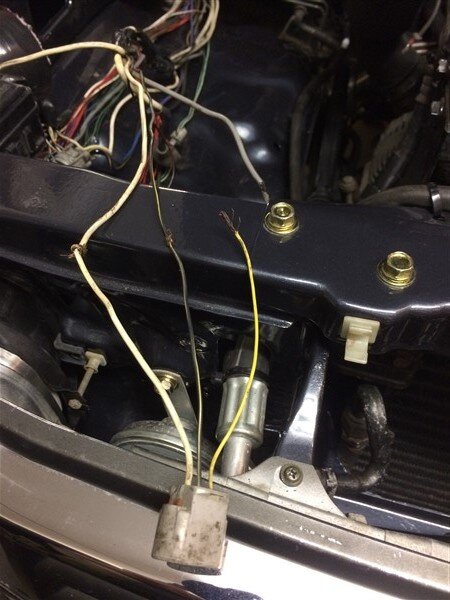

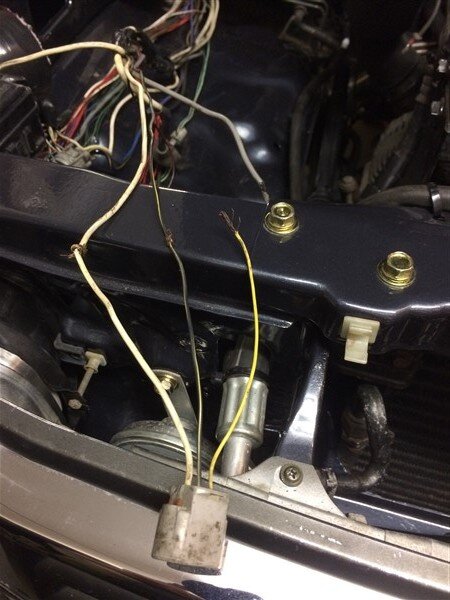

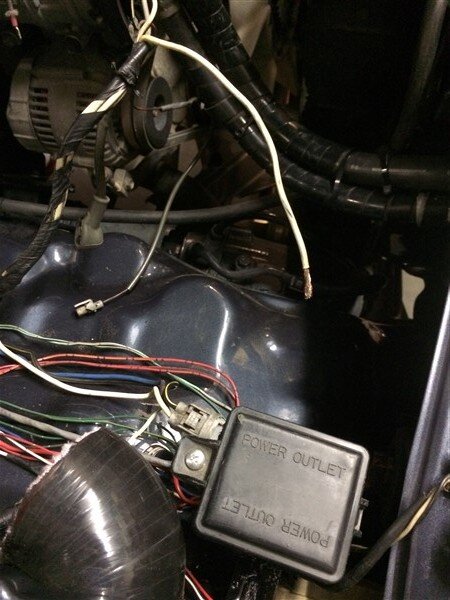

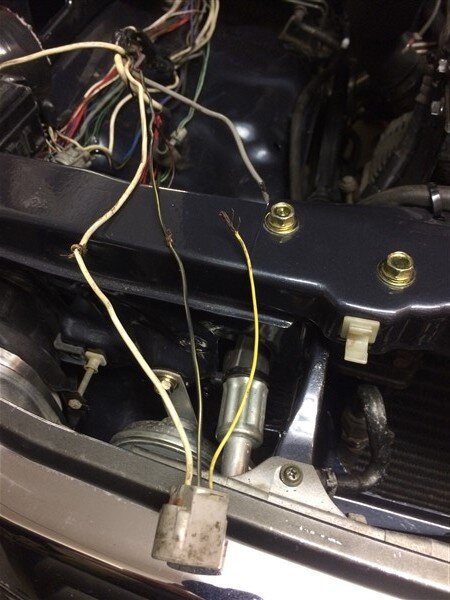

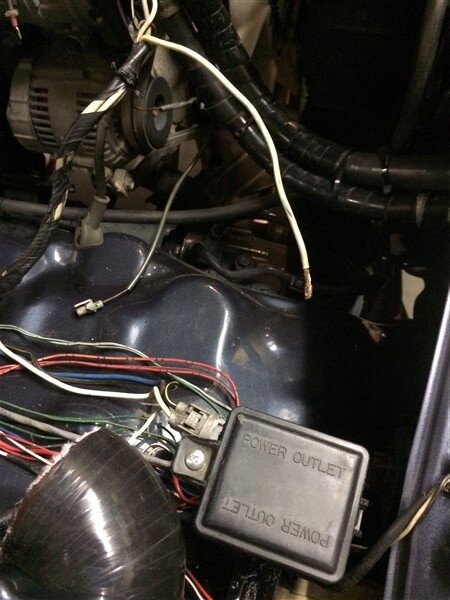

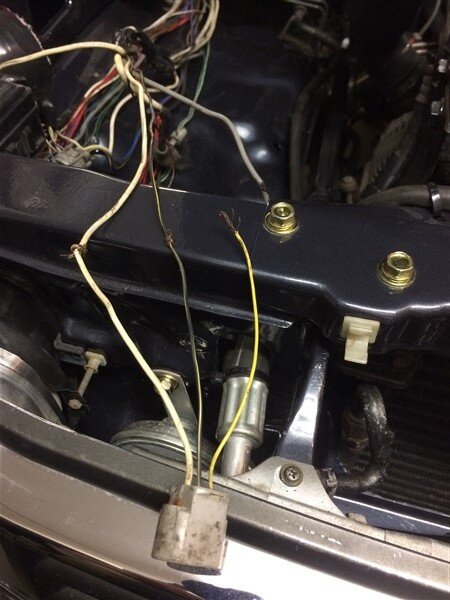

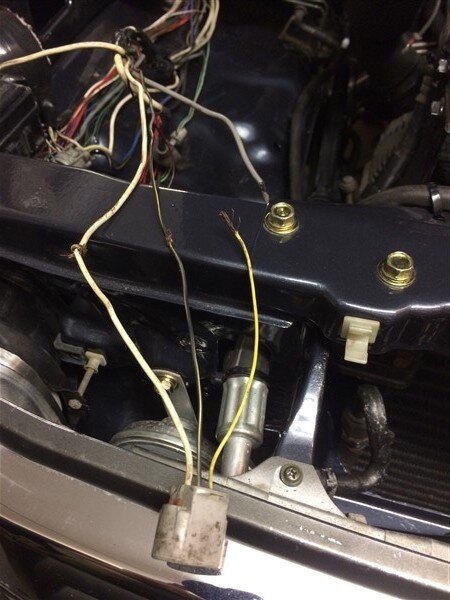

I need some help working out how to connect the plug for the alternator please.

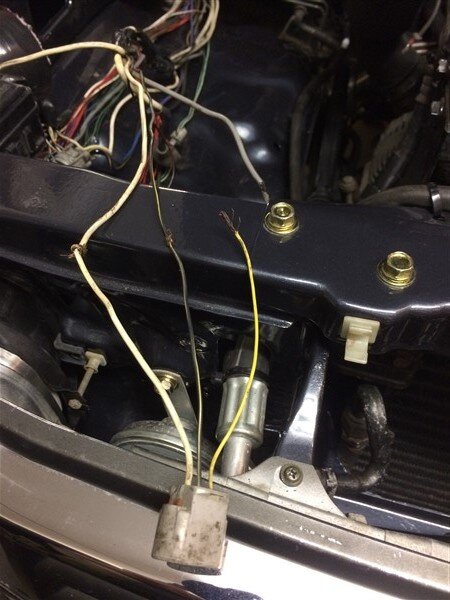

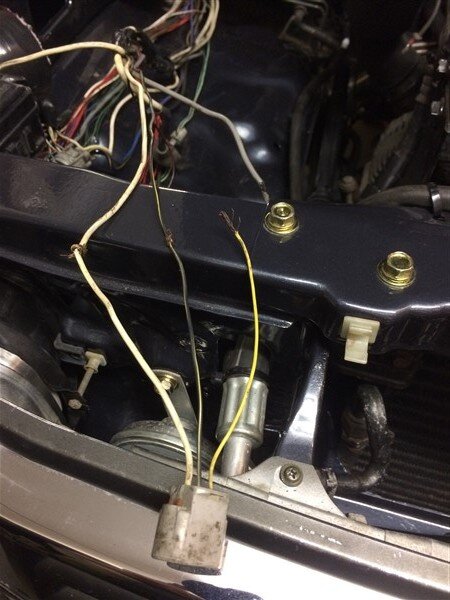

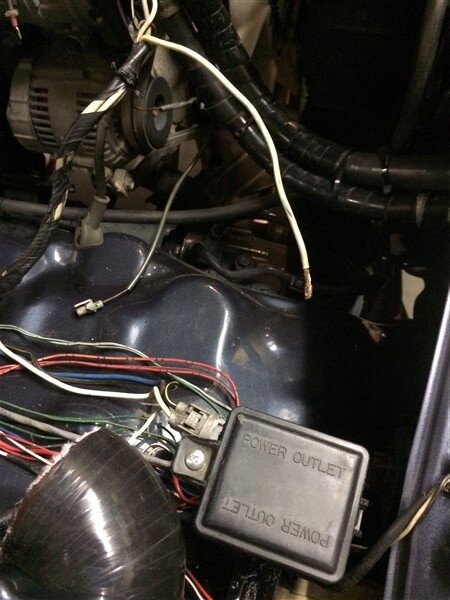

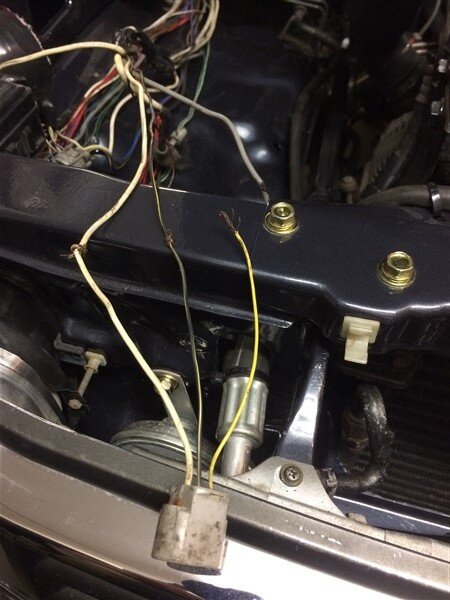

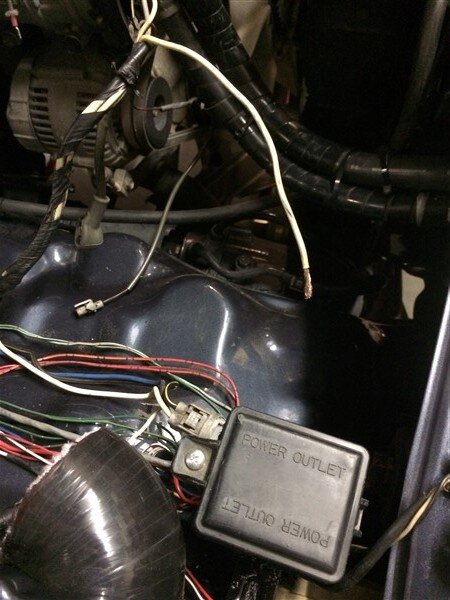

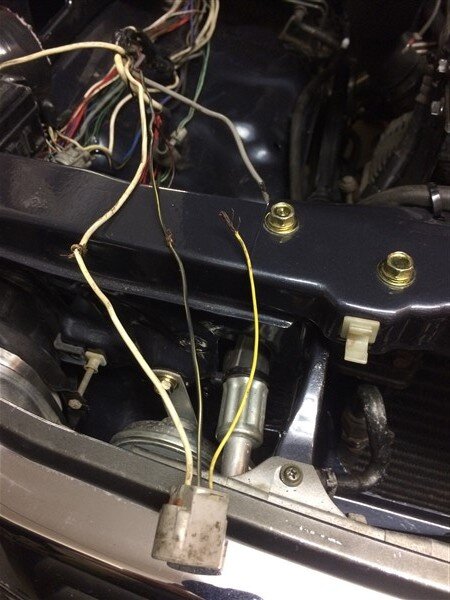

I have 5 wires in total going to the alternator, 4 of which went to a plug on the alternator, or at least on the original 2-lt motor they did, I think.

Where as my 1KZ only has a connector for 3.

The wires on the loom of my 78.

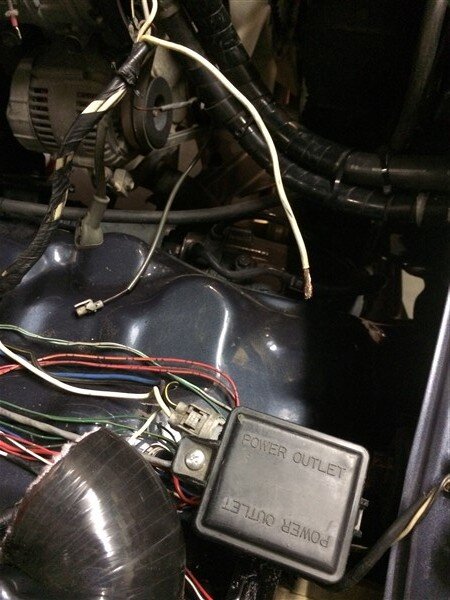

One of which goes to the accessories power box which is strange because non of my other 70's had an alternator wire.

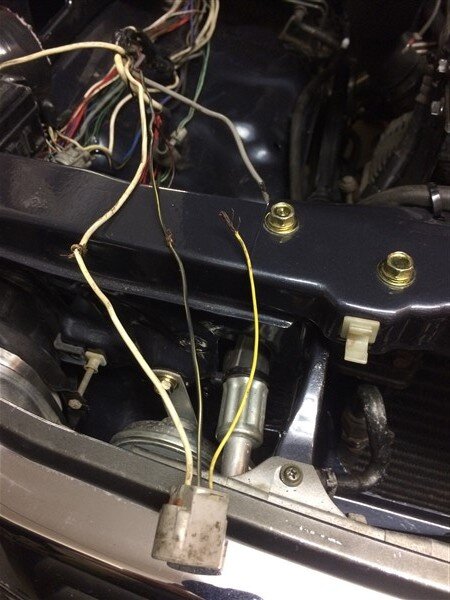

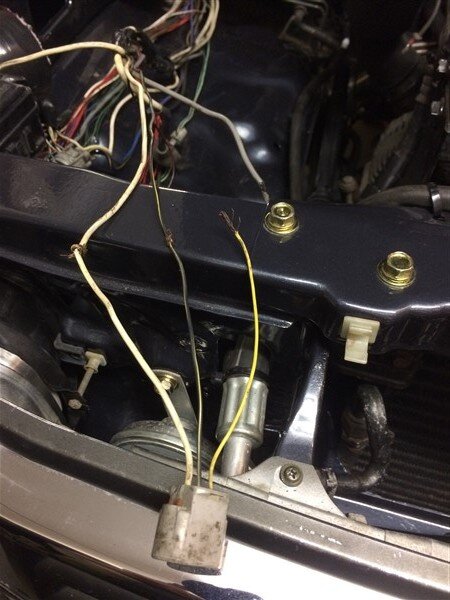

This is the plug for the 1kz alternator.

I can work out 2 of the wires as their quite obvious.

But I'm a bit unsure about the others, particularly this one which is almost like a coaxle cable.

Doesnt look like it should go to my yellow, but maybe it does?

So I'm hoping one of you guys might be able to help.

Back to the build.....

I cleaned the last piece of chrome trim for the rear roof gutter, I had hoped to use one of the KZJ78 ones but sadly that one was damaged, presumably at the same time the rear doors got so damaged.

So I cleaned the paint off my original one.

And got that fitted.

I fitted one of the rear door cards/trims.

I was going to fit the passenger side front one next.

But first I needed to sort out the hideous MDF speaker mount that has been attached to the door.

Removed it and was impressed to find that its a proper shop bought laser cut item and not something some one has bodged together themselves.

Decided to cover it in grey vinyl that I had left over from a previous project.

Covered it completely first and tried to get it nice and tight.

Then cut the middle out and mounted it on the door with the speaker.

But sadly its not perfect, so will have to come off and be re-done.

I'm going to redo it and this time use a hot glue gun to help stick the vinyl in place as I go, so hopefully I wont have any of those loose bits.

I did lots more parts cleaning while the Mrs was in bed.

Then laid them all out to dry.

And hung all the door opening seam seals up to dry.

I used some washing line to re-glaze the smaller rear door.

Next I looked at the seat belts, which would prove a much bigger and time consuming task than it should have been.

The KZJ78 that I got all the seat belts out of had sadly been sat for 2 years with no sun roof or doors on it and the weather had taken its toll.

All the seat belt mounts were rusty.

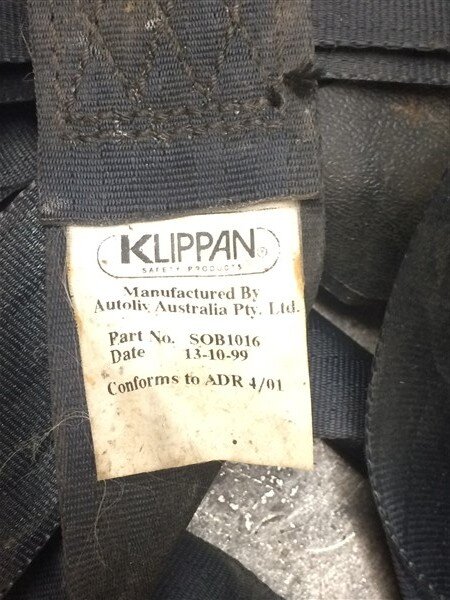

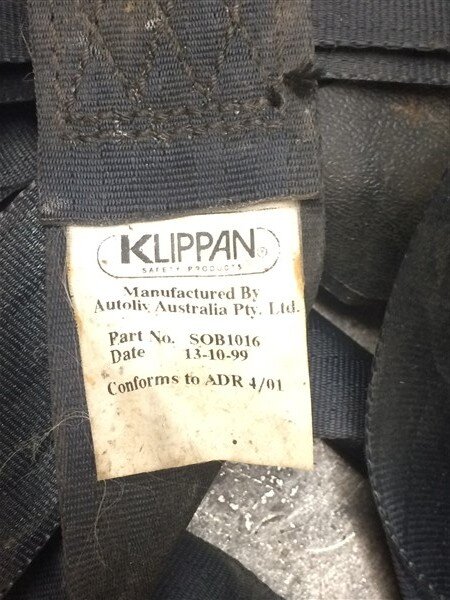

On closer examination non of them are genuine Toyota ones.

Nor were any of the ones that came on my 78. So I can only presume that to get these imported vehicles to meet Australian Design Rules (ADR compliant) they have to change the belts.

A quick look on Toyodiy with my vin number revealed that it left the factory with only lap belts in the rear, which seems strange as the plastics are made around seat belts being installed, as is the body with its M10 fine thread captive nuts every where.

So then I tried the KZJ78 vin, thinking maybe it was just because mine was an earlier 78, but I got the same result, no rear 3 point belts fitted, only lap belts.

So I can only presume that at that time JDM vehicles didnt get rear 3 point belts, or certainly not these 70 series Prado's.

Anyway, back to the seat belt situation in the 78.............

I wasnt keen to fit rusty parts so decided to try and fit some front 79 series Ute belts I bought 4 years ago when I imported my LJ70.

It bolted in perfectly!

But sadly it wouldnt fit into the stalk on the rear seat.

The rear seat belt stalks were designed to take belts thats tang was 5mm narrower.

So then I dragged LJ's old rear seat out, something which hasnt been fitted for 7 years, but that I'm glad I kept as it will be perfect for carrying my kids when it goes in the soft top body.

But sadly the seat belt stalks on it were wrong too.

So at this point I thought right, Toyota fits the slightly wider tang belts to the front and the narrower to the rear. I will buy some rear seat belts from a new V8 76 wagon or duel cab ute.

Located some, agreed a good price on them, then asked the guy to measure them and discovered that Toyota now fits the wider front tang seat belts to the front and rear of its 70's!

So at this point I thought f*** it!

Fit the rear 2 belts out of the KZJ78, as at least their not red like the ones that came in my 78.

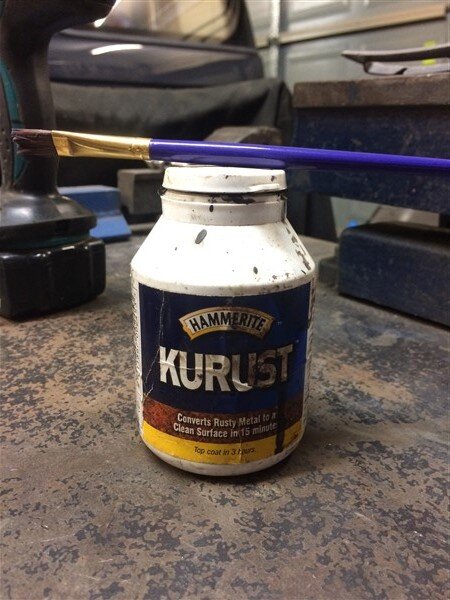

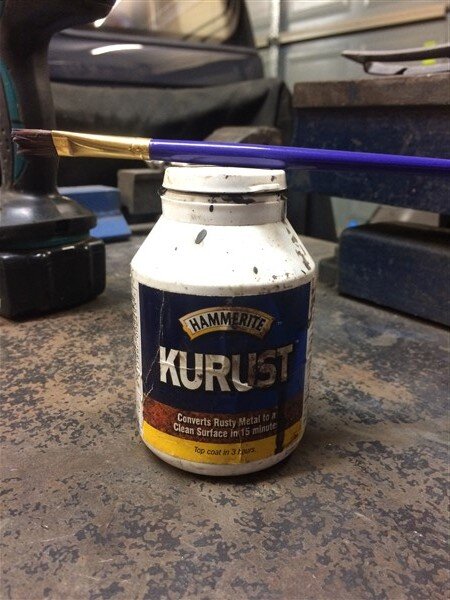

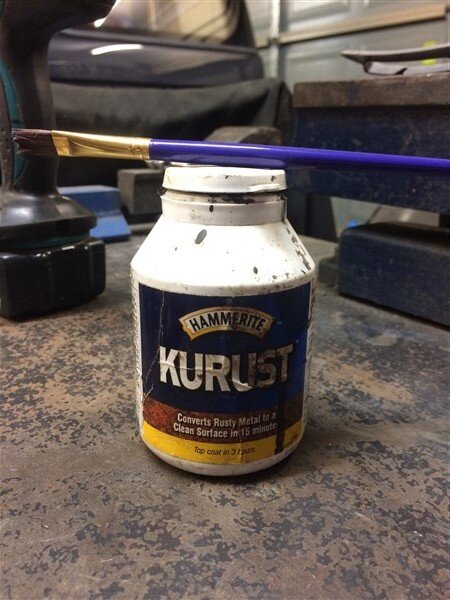

They were a little rusty.

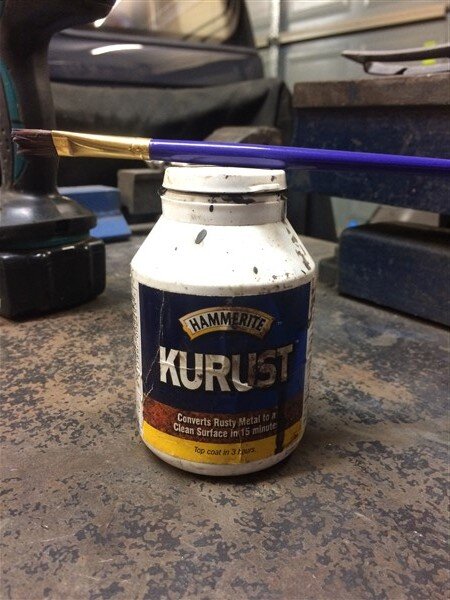

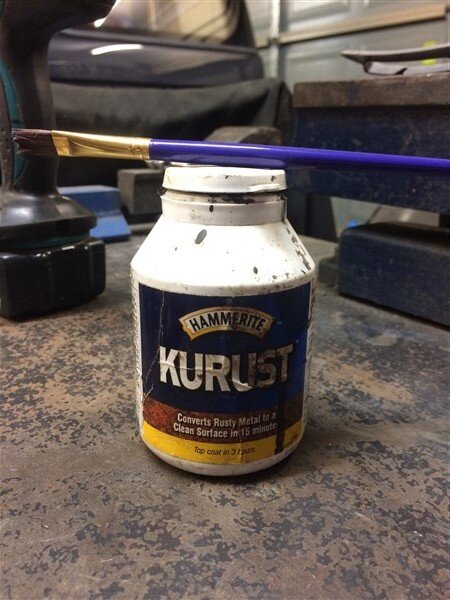

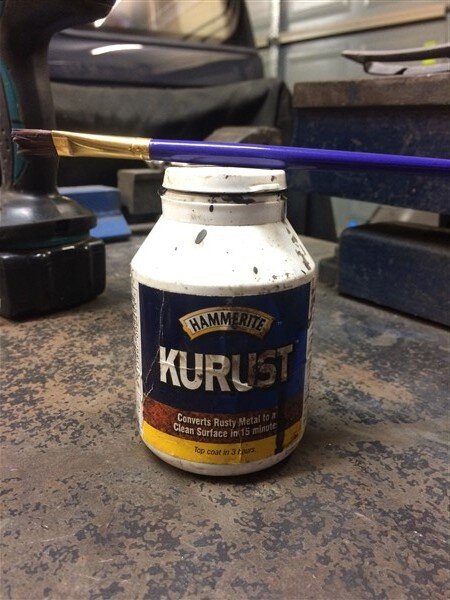

Cleaned them up as best I could with a wire wheel in the drill.

Obviously couldnt get this bit very easily sadly.

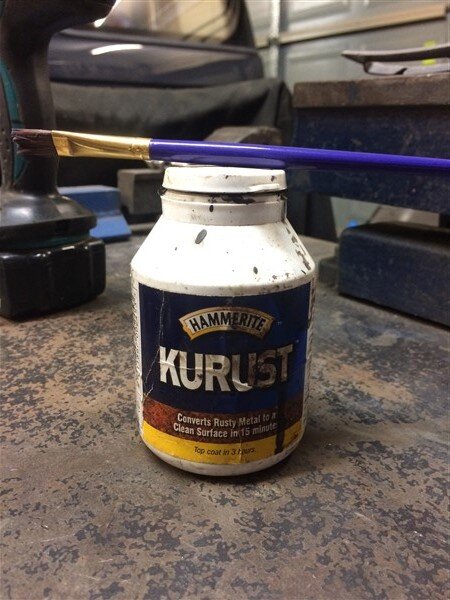

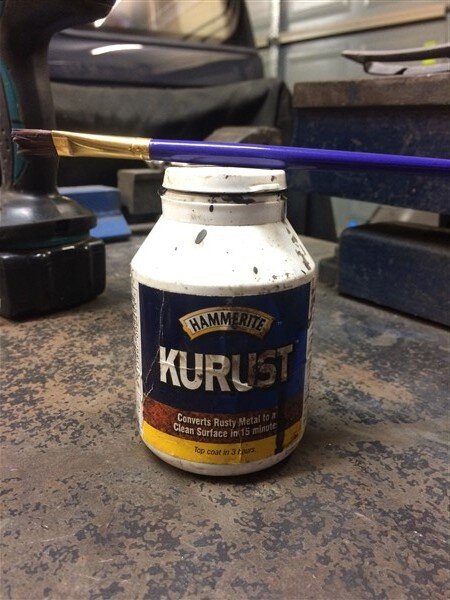

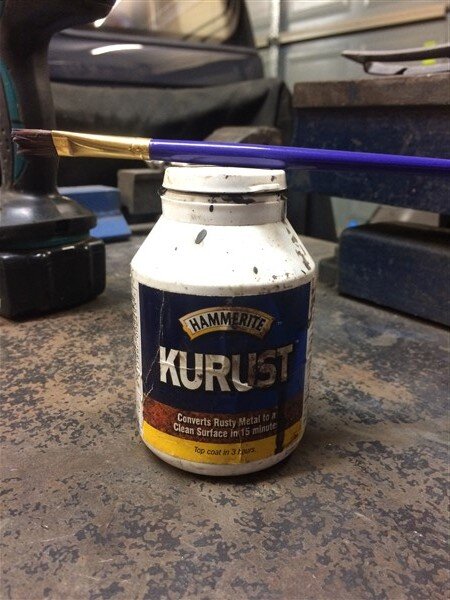

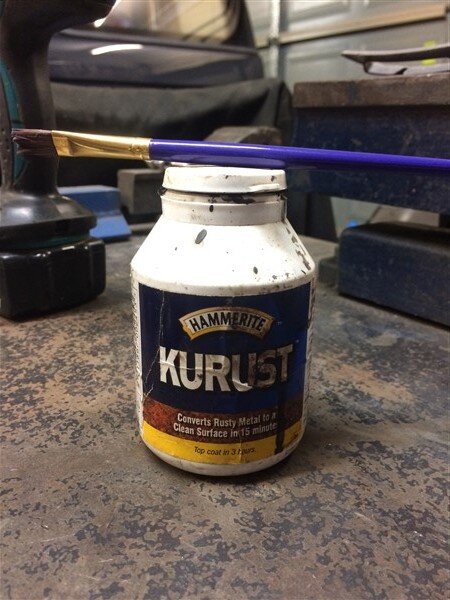

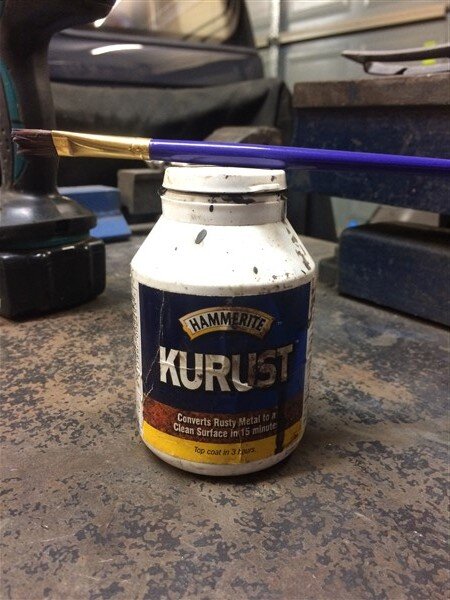

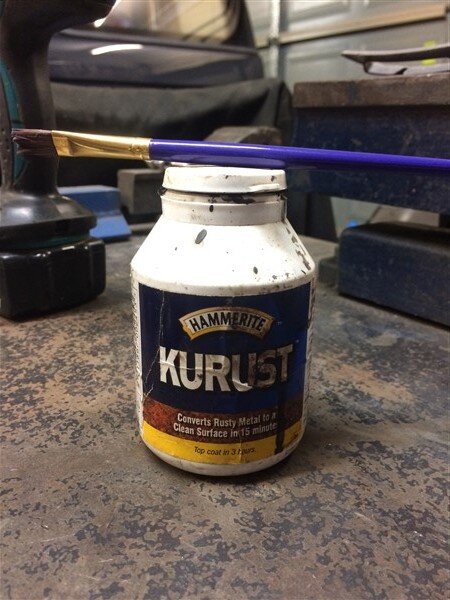

Didnt want to risk using my good acid based rust killer next to the belts encase it damaged them, so settled for some much weaker Hammerite stuff I brought over with me when I emigrated.

Gave them a good coat and left it to soak for a while.

Then I masked off the belts.

And gave them 2 coats of etch primer.

Followed by a few coats of satin black enamel paint.

Then they could finally be bolted in place!

And I could start putting the inside back together with all the plastic trims.

Decided to fit the grey, VDJ79 seat belts in the front as they are much better quality than the aftermarket ones these 78's got fitted with after being imported.

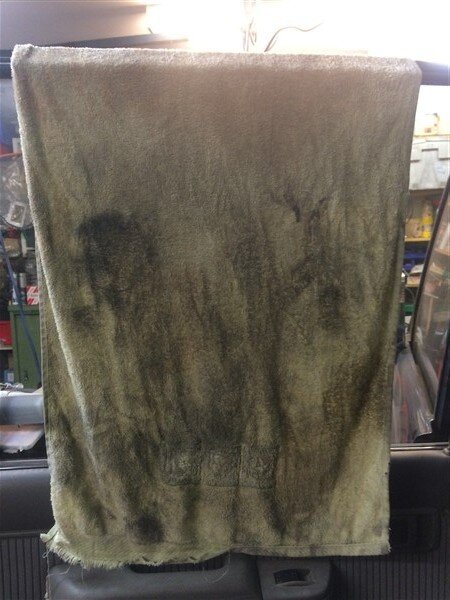

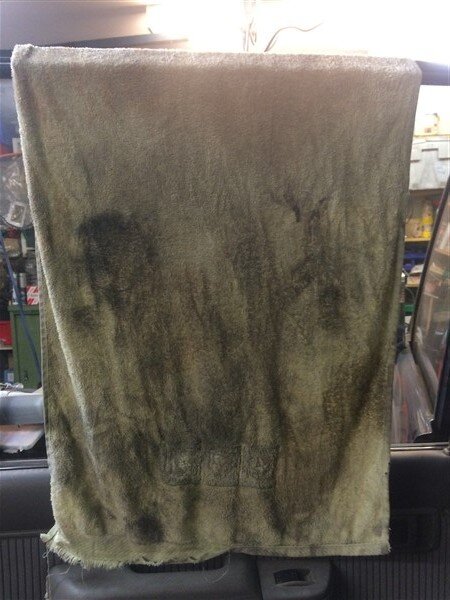

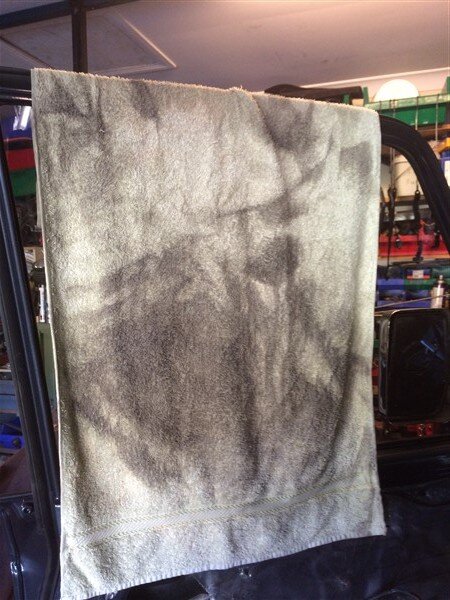

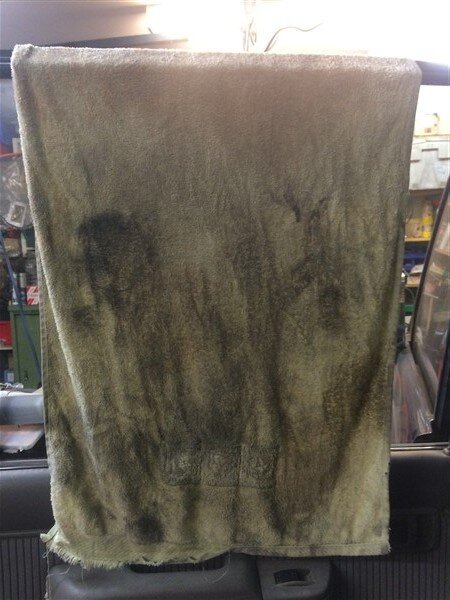

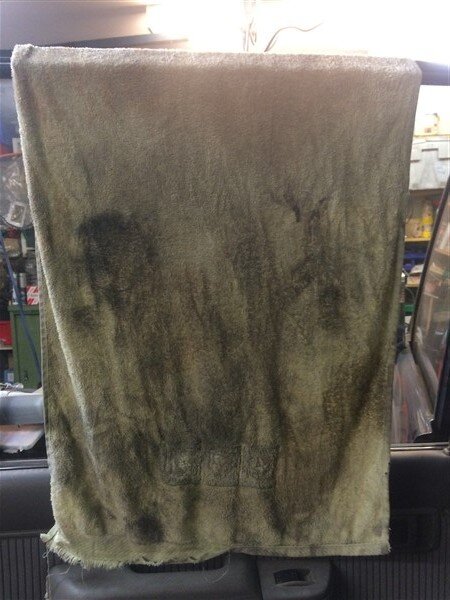

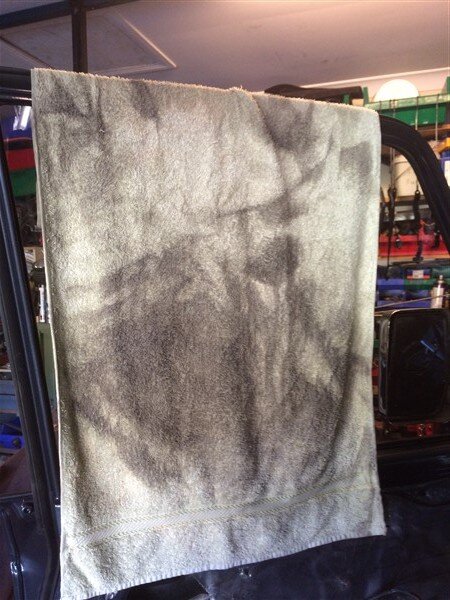

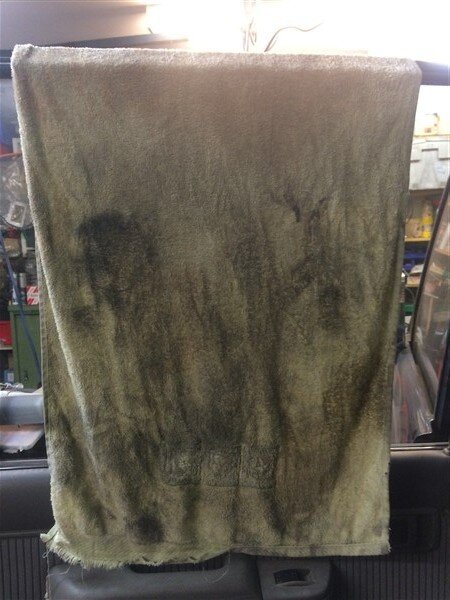

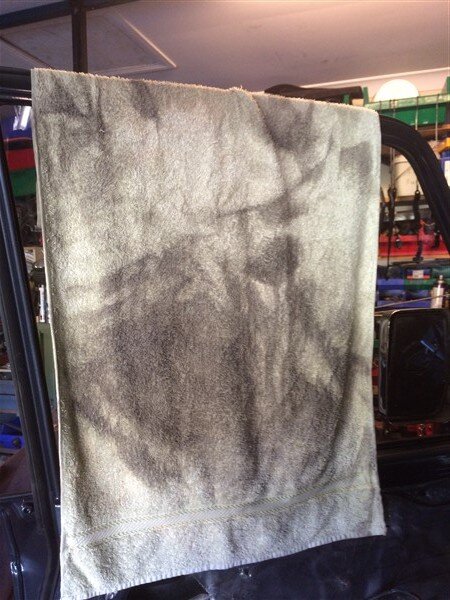

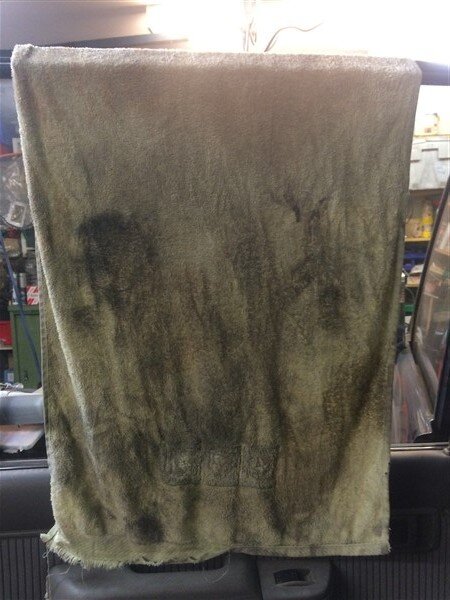

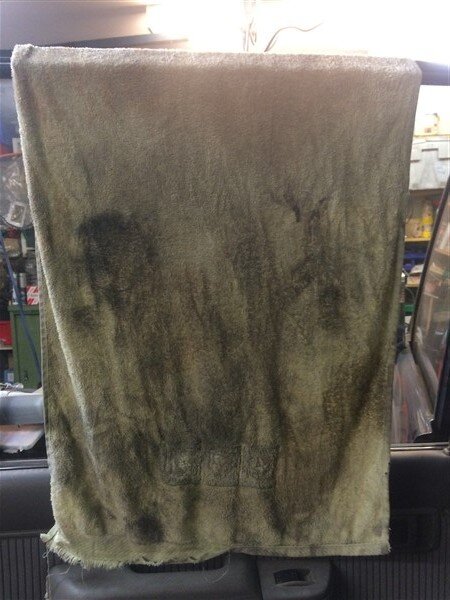

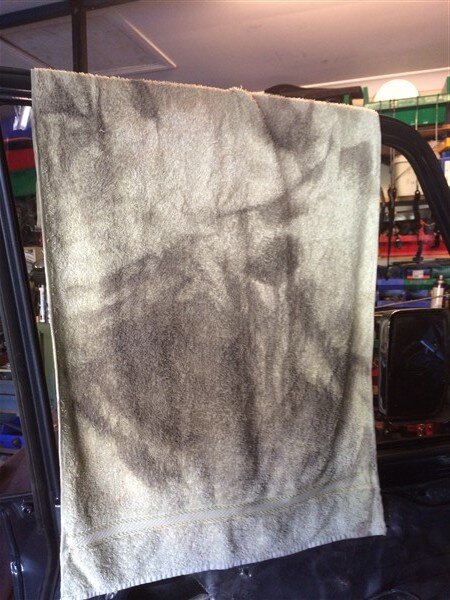

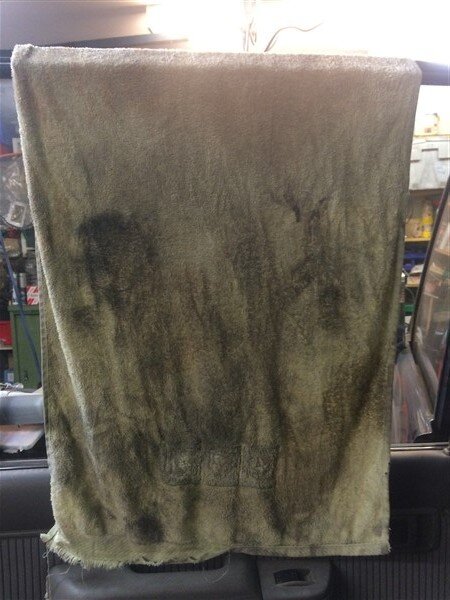

The roof lining was filthy when I got the 78 and I mean filthy!

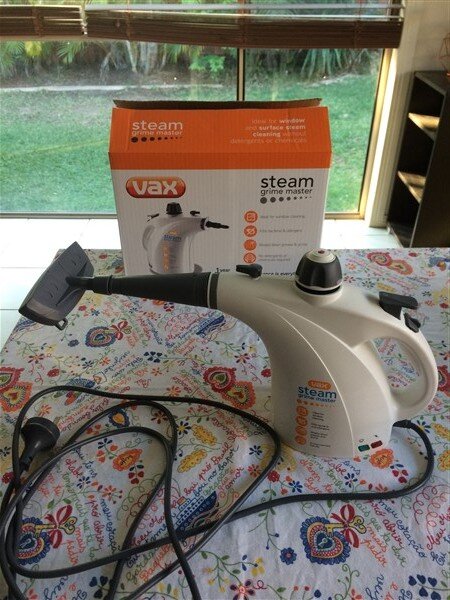

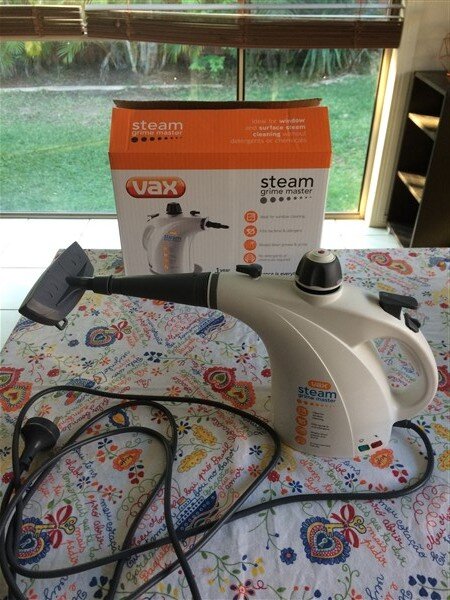

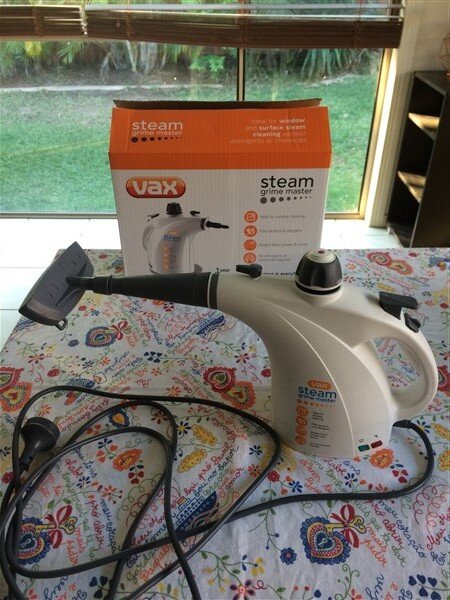

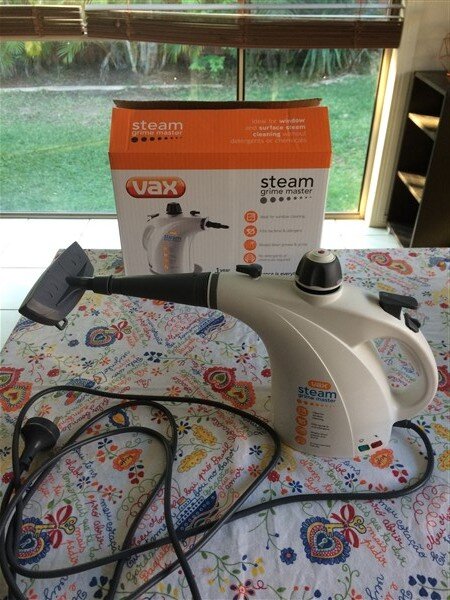

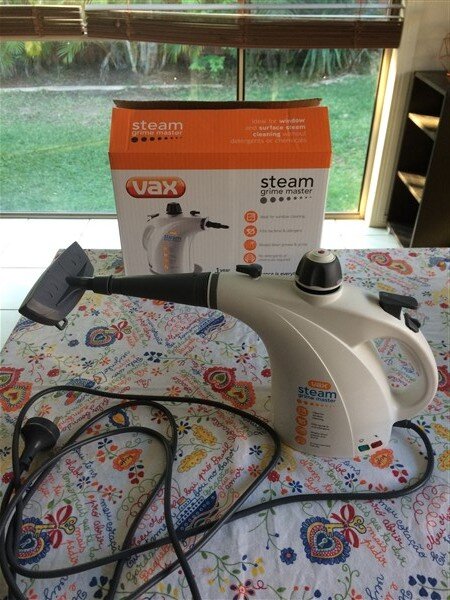

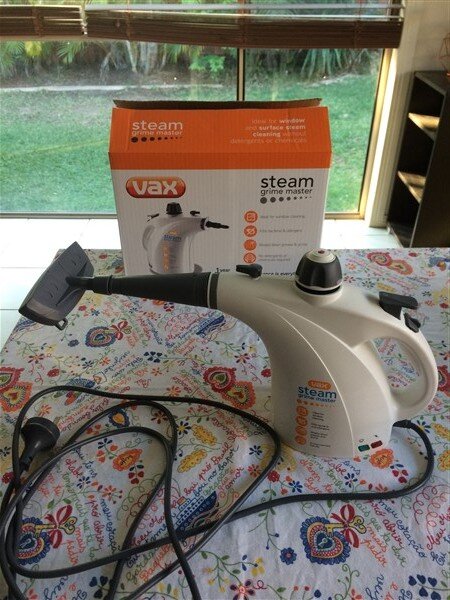

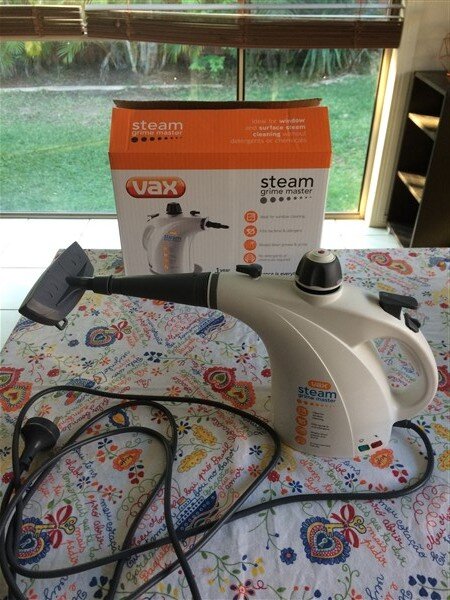

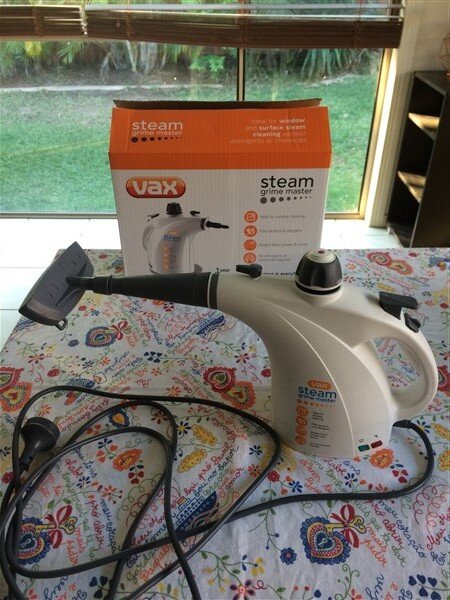

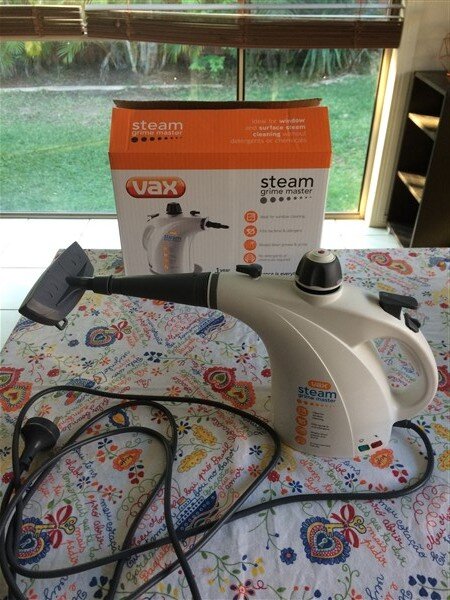

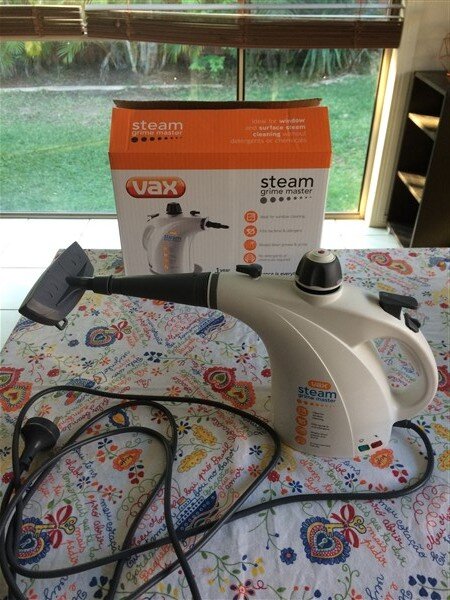

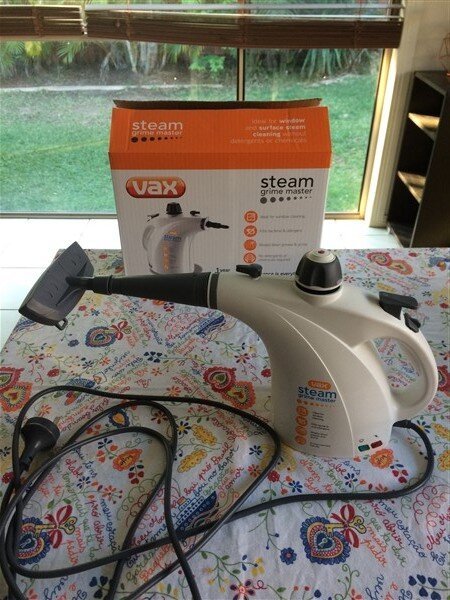

So this week when the wife wanted to clean her old car as we were getting it ready for sale, I suggested we should buy a decent hand held steam cleaner.

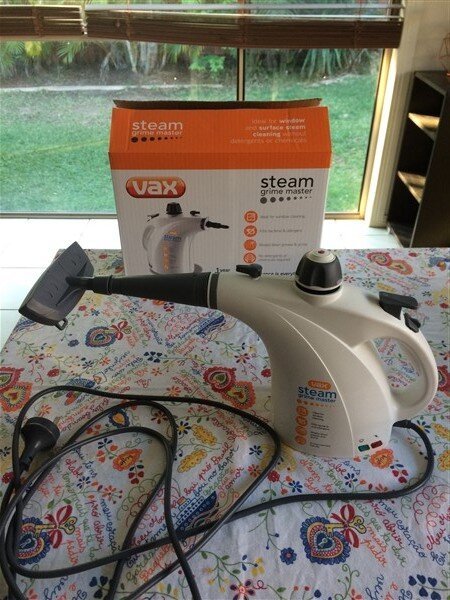

So we bought this.

Which has proved to be excellent for cleaning the headling and car upholstery!

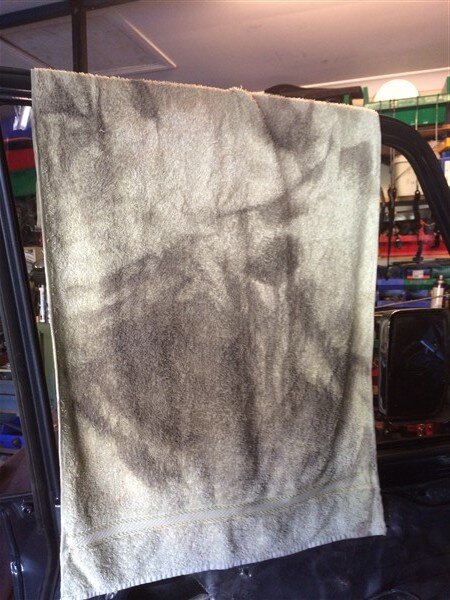

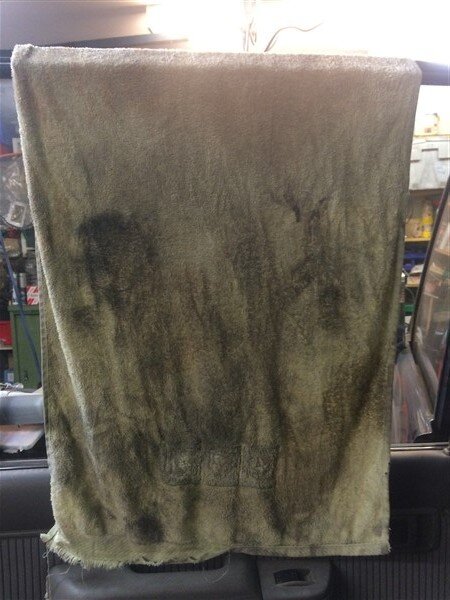

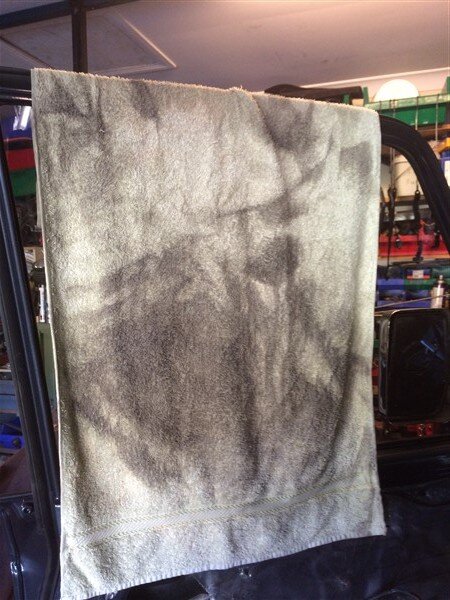

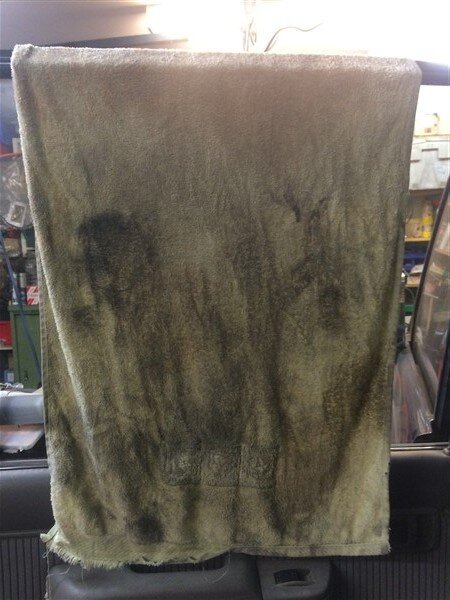

The heads get dirty pretty quickly.

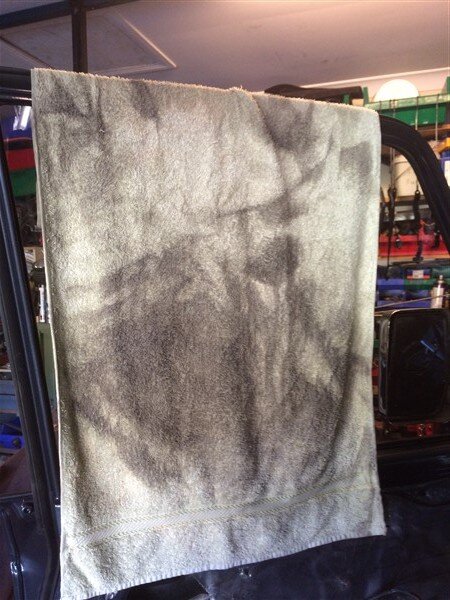

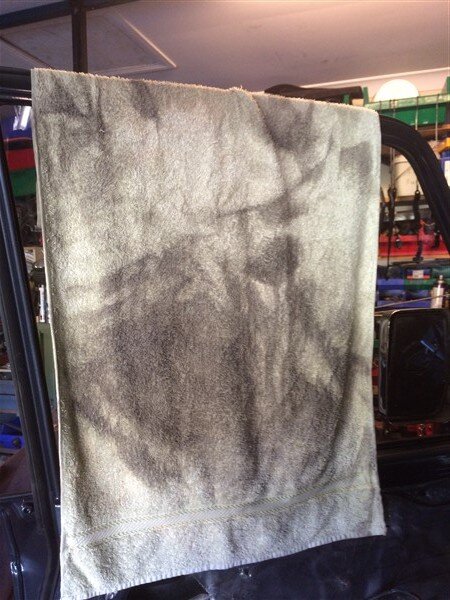

But the technique I've discovered which works best is to give it a good going over with the steam mop to loosen all the grease and grime and then use an old towel to rub/wipe it with and all the dirt ends up on the towel.

All of the interior grab handles were pretty gross too.

So they too got a good scrub in the kitchen sink.

The sun visors that the 78 came with had seen better days.

So I kept the ones out of LJ's old body, before I sold it, especially for this build.

Got those fitted.

Along with the rear view mirror, which I never realised before just how perfectly the mirror and visors fit together.

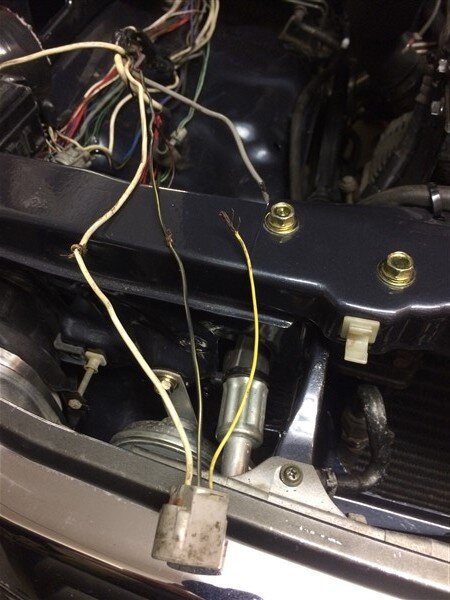

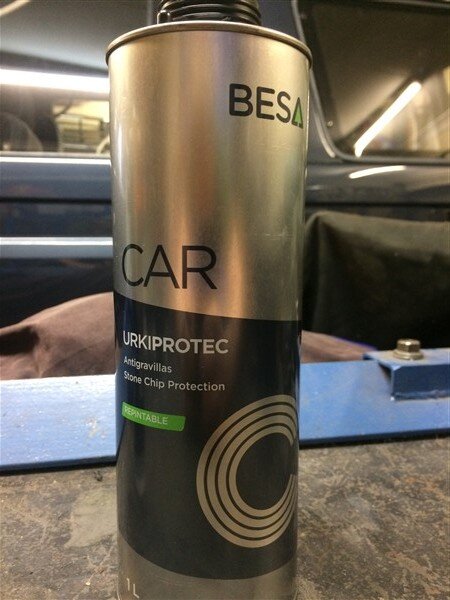

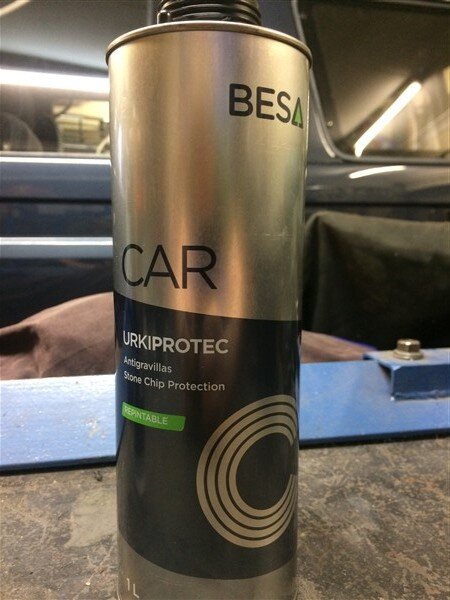

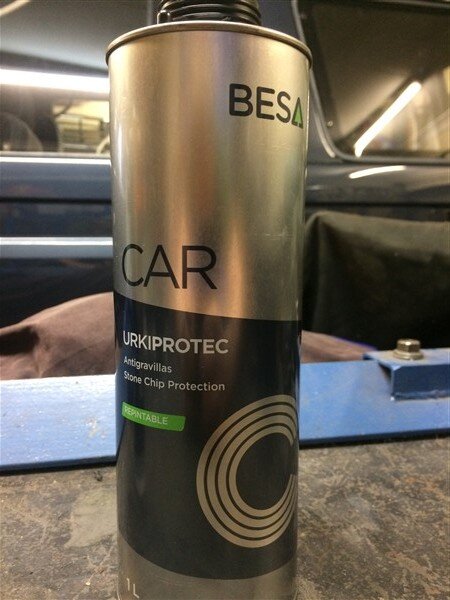

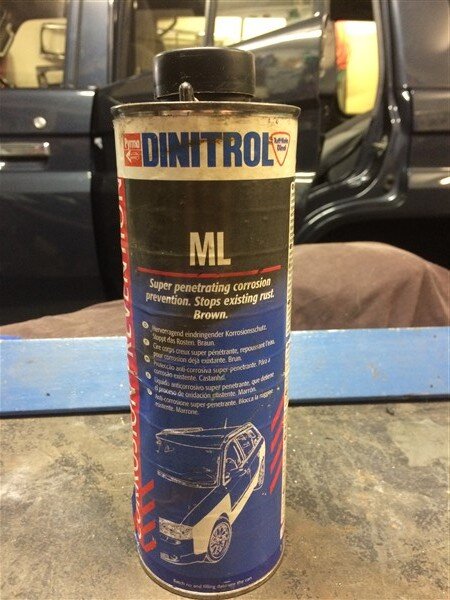

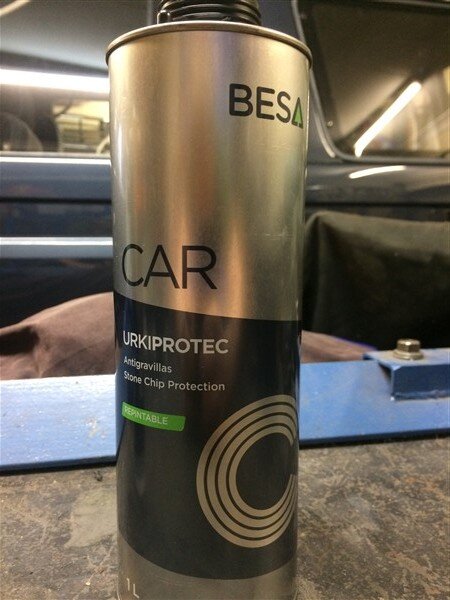

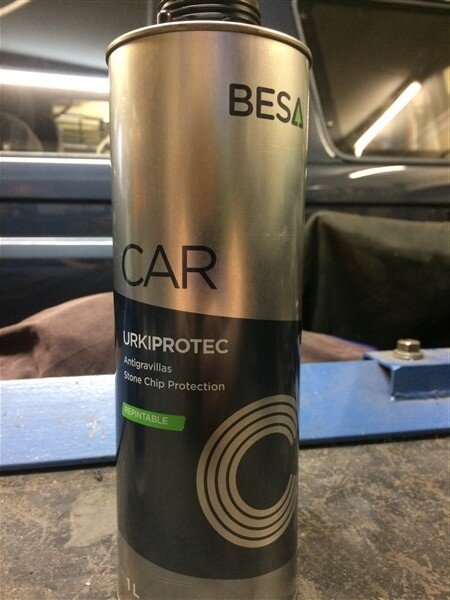

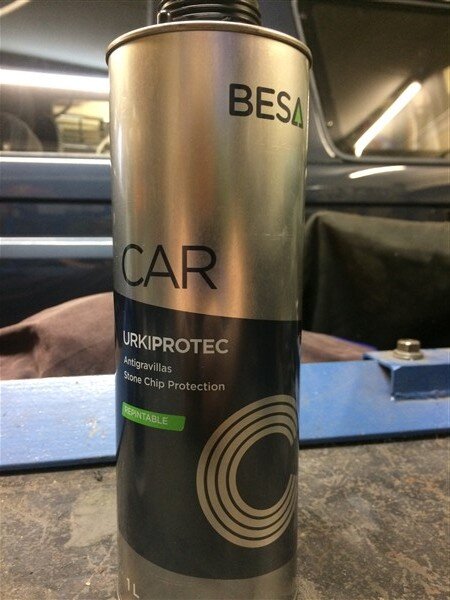

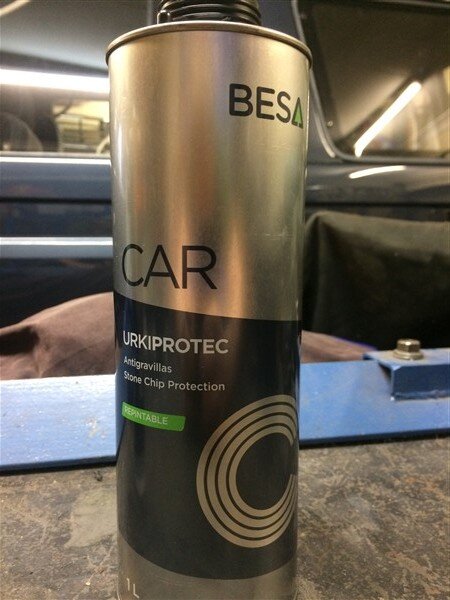

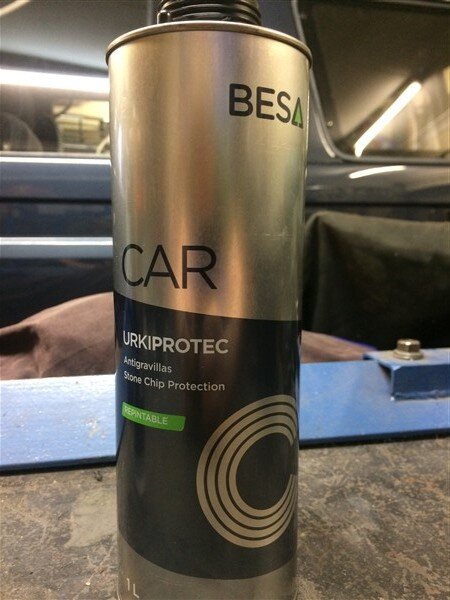

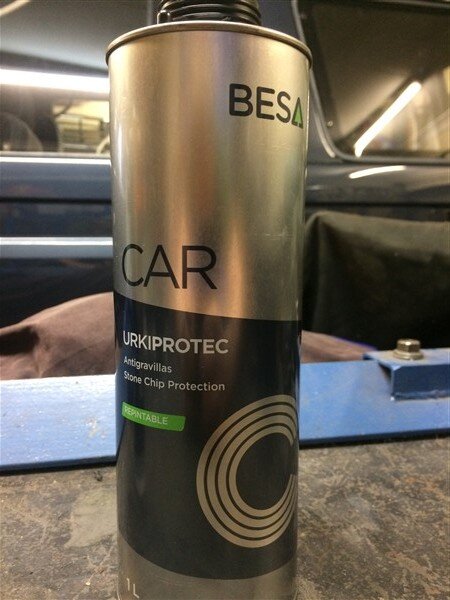

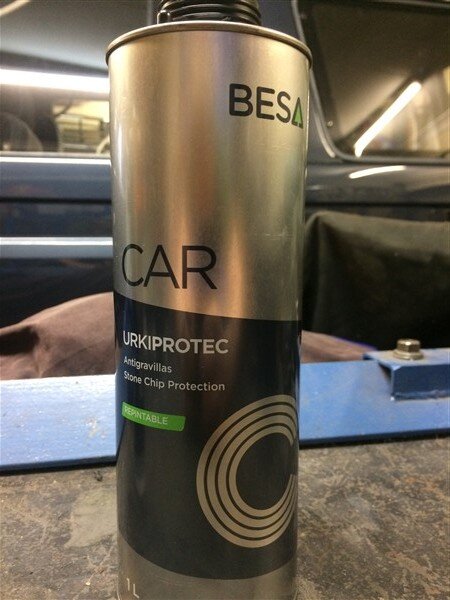

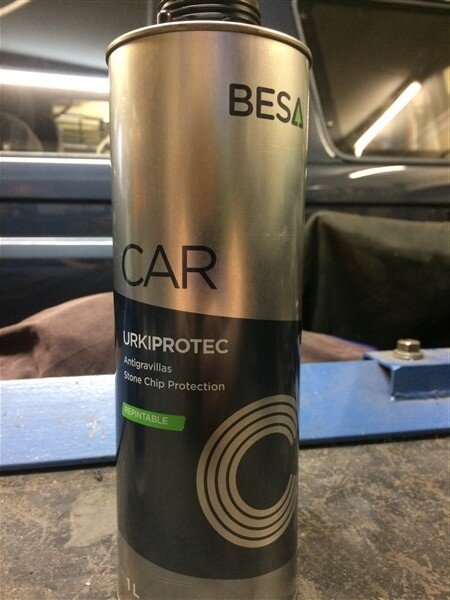

I found a great new automotive paint shop near where I work and picked up some seam sealer to seal where the panel shop forgot to and some stone chip to spray the wheel arches with.

This was a bargain at $15!

The last place ripped me off for $40 for the last one.

Seam sealed the door.

And also the bottom of the rear quarter panel where I did the rust repair.

*You can see the grey paint that has dripped out, thats from where I gave the inside of the quarter panel a good coat of paint a few days previously to ensure no rust can start.

I also seam sealed the inside.

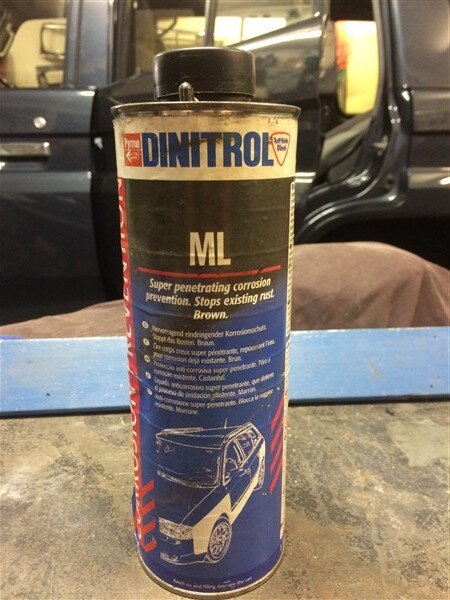

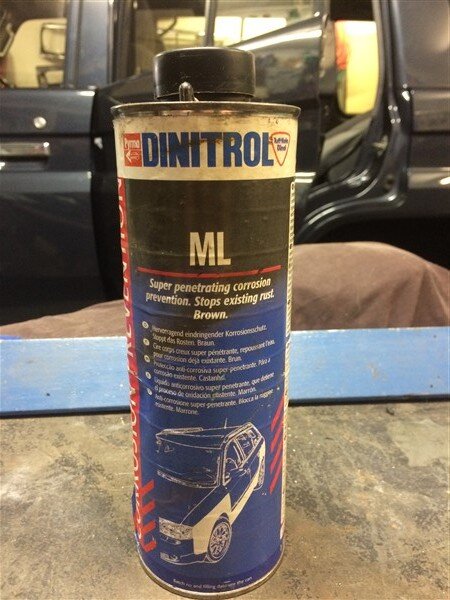

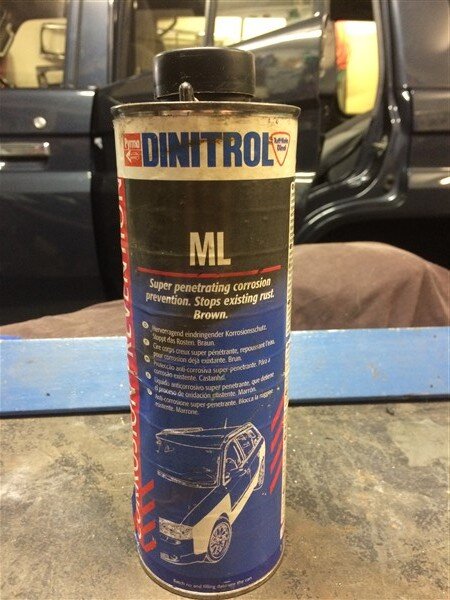

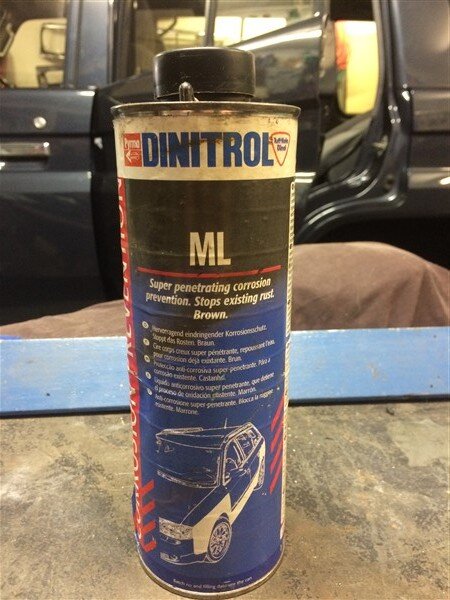

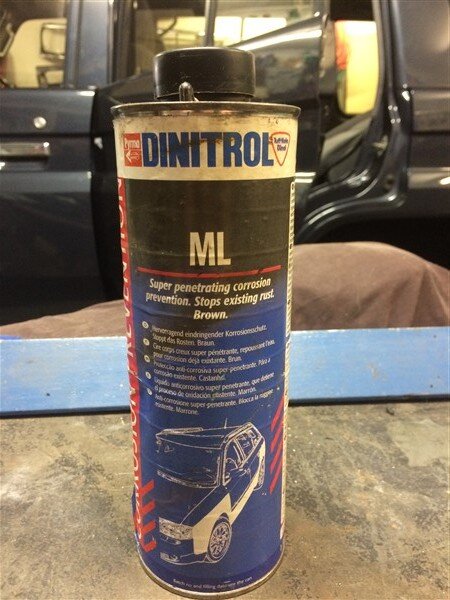

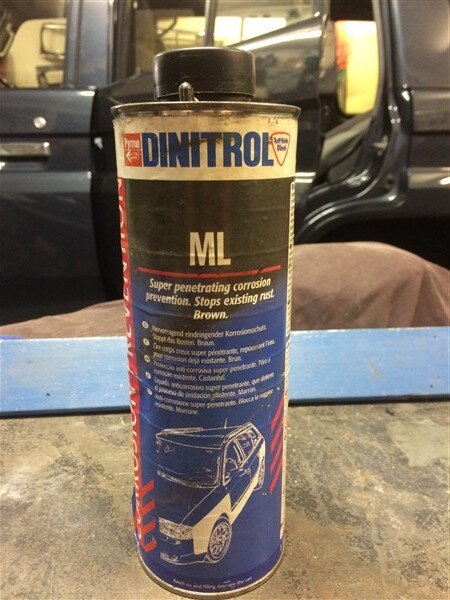

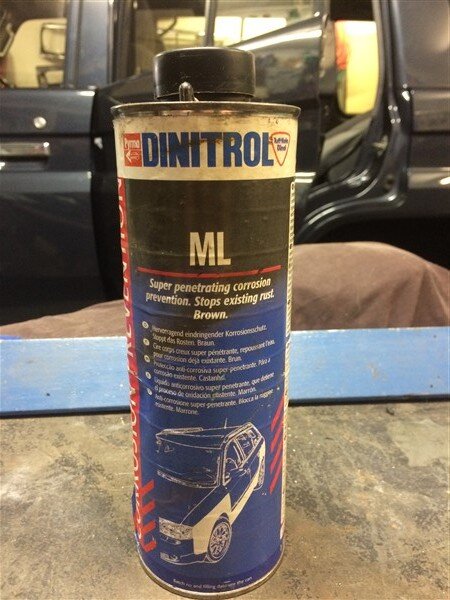

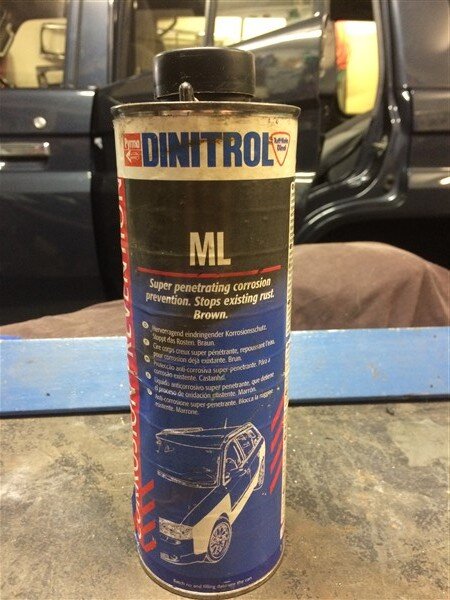

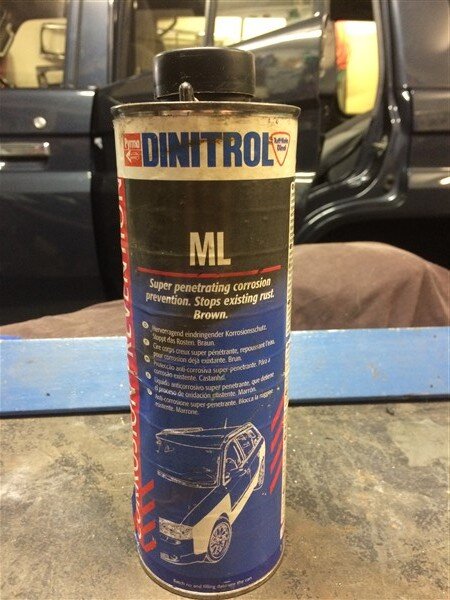

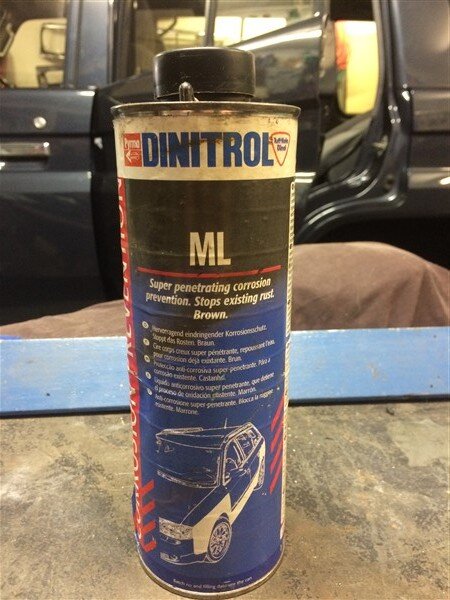

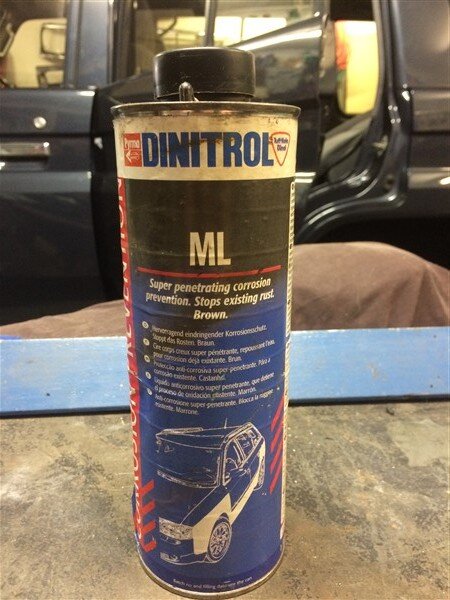

Once that was all dry it was time for some Dinitrol.

I'd forgotten what a bloody messy job it is!

Gave the inside of all the doors a good coat.

And the rear quarter panels.

Carefully positioned tubs to catch it as it leaked out of the drain holes.

Mounted the jack next.

I need to get the tools to go with it, although its unlikely I will ever use it as I always use my high lift, which is very safe and stable with the attachment fitted which fits securely into tube welded into my rock sliders and bull bar, its also super quick and saves having to get down on your hands and knees to position a jack under the axle.

The door cards went on next.

Not sure if I will mount speakers in here or not as the boot will be pretty full with the fridge, water tank, drawer system and camping gear.

But I salvaged the speaker covers off the ruined KZJ78 rear door trims, so I will probably clean and paint them up to at least cover the holes.

Other side went on.

And the other rear side door card.

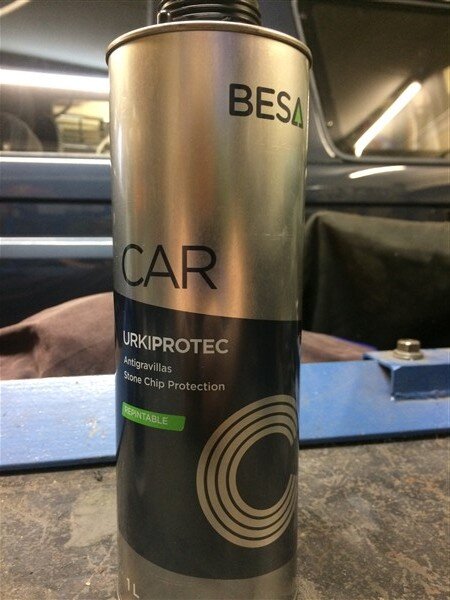

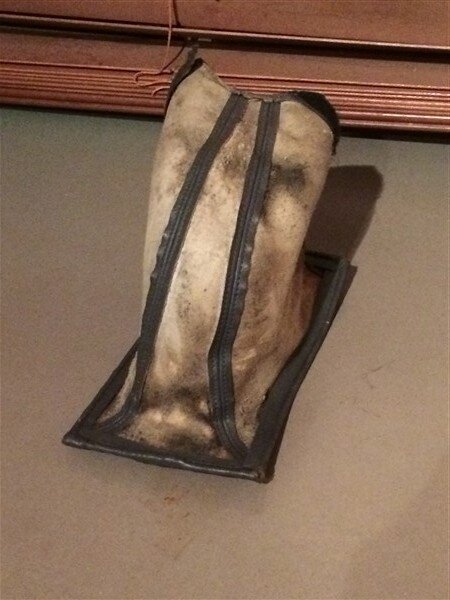

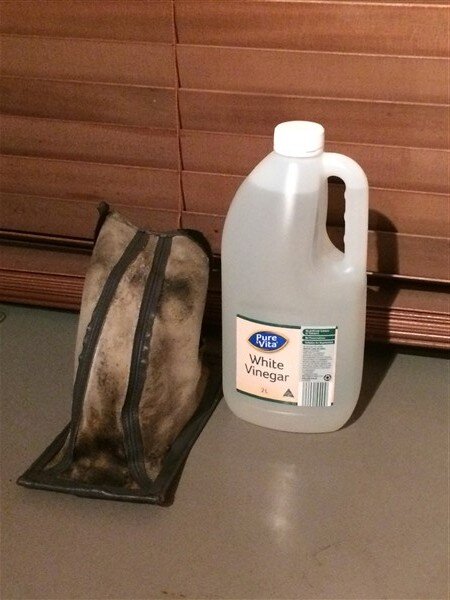

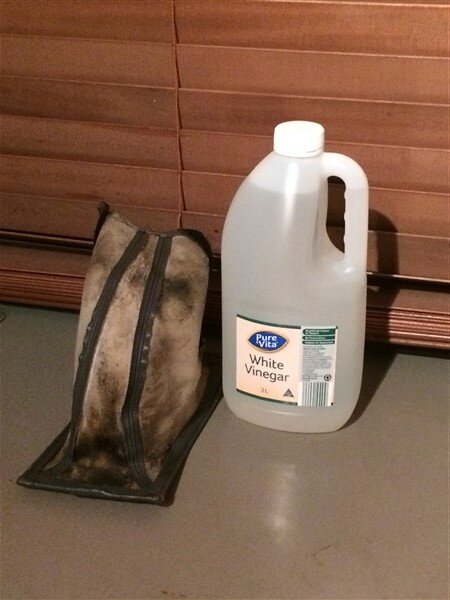

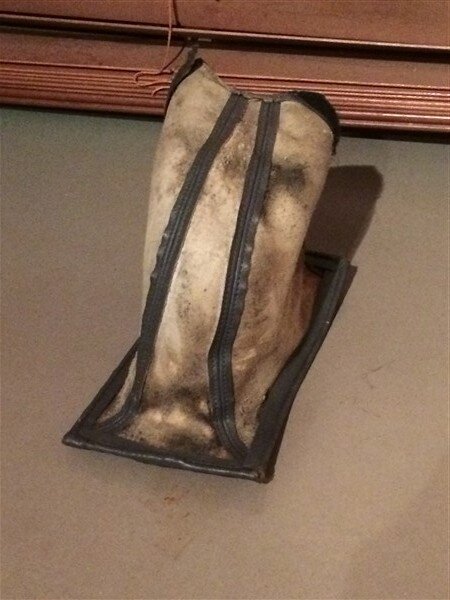

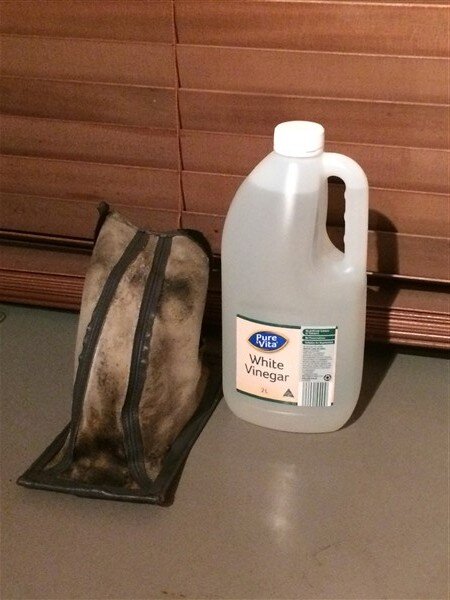

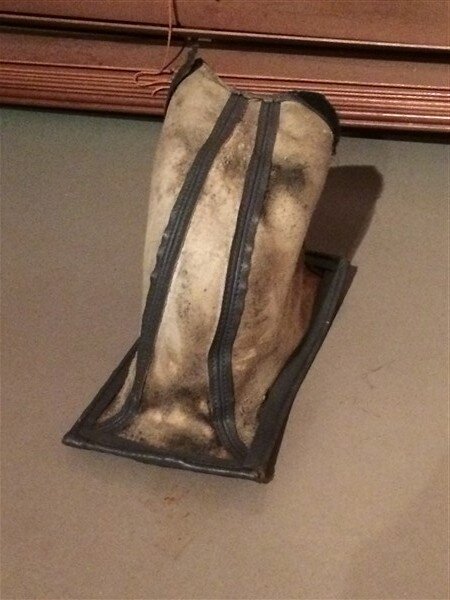

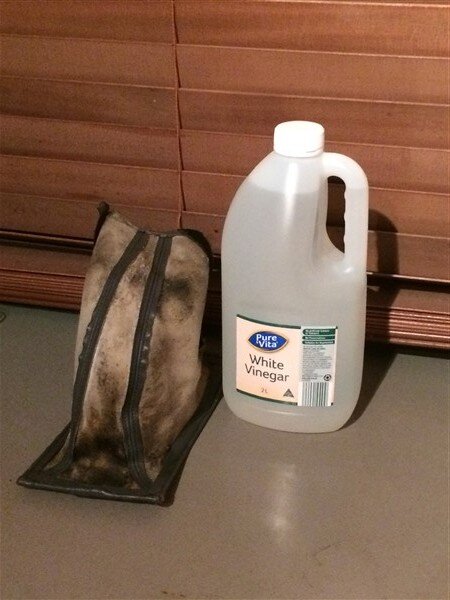

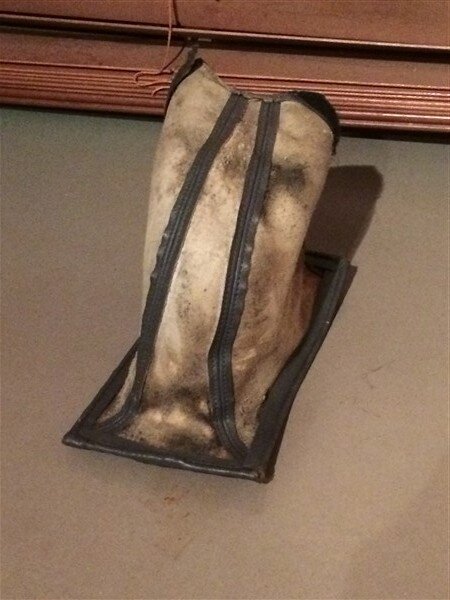

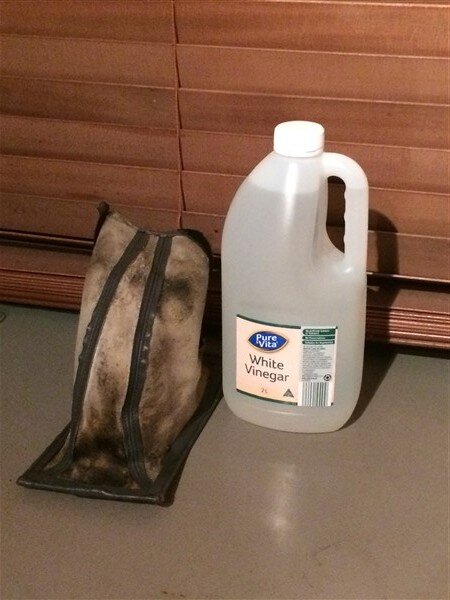

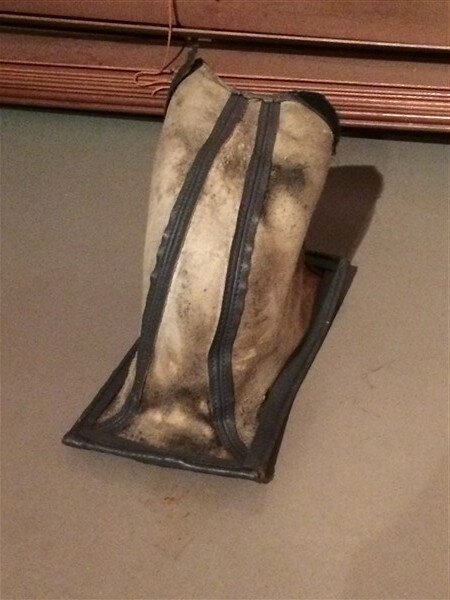

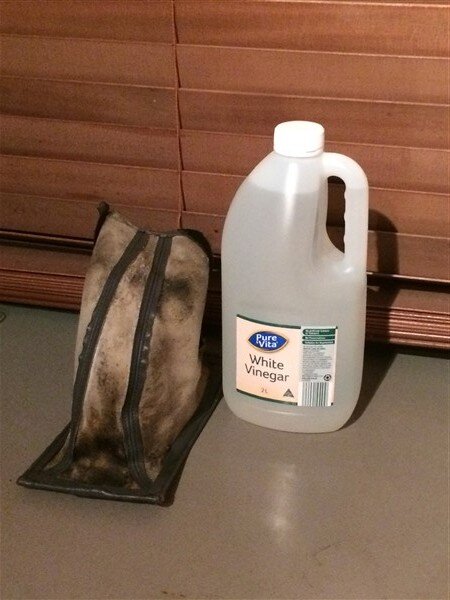

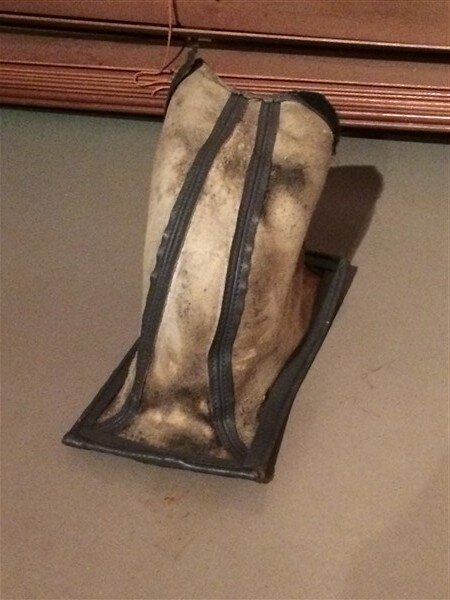

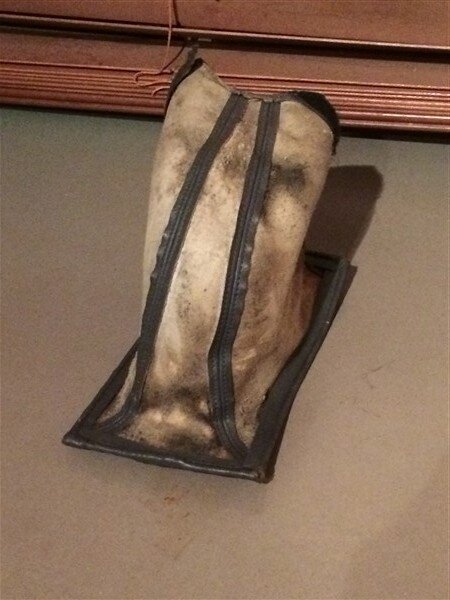

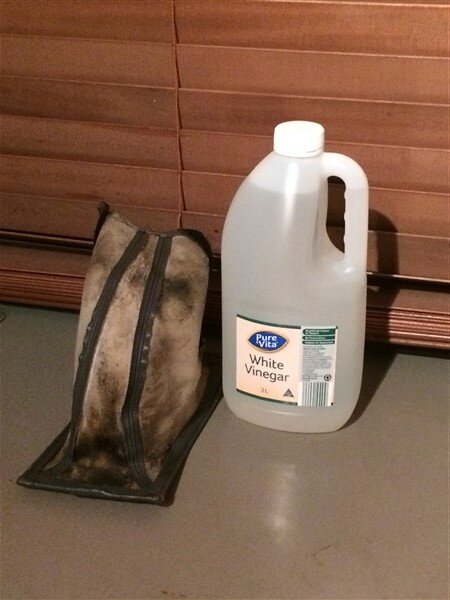

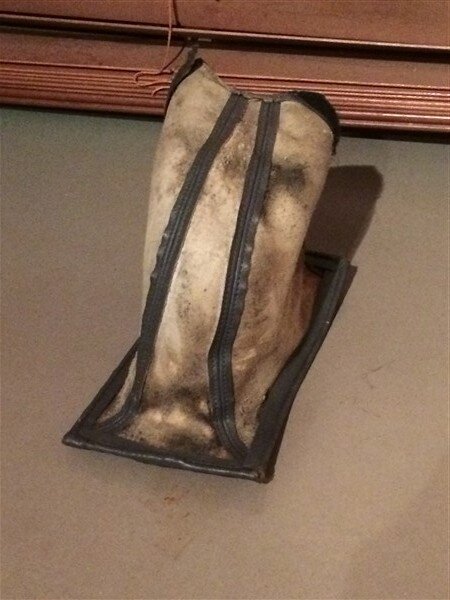

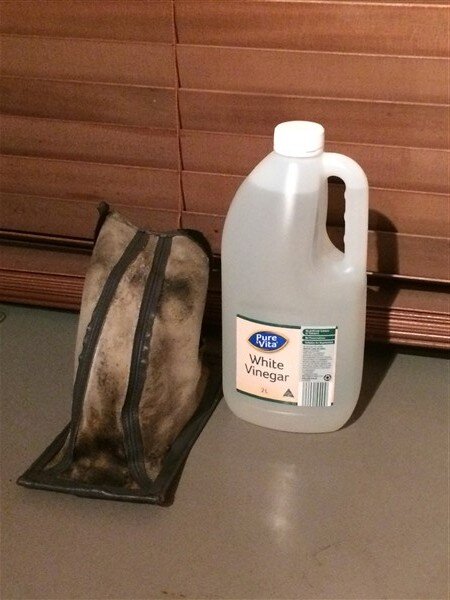

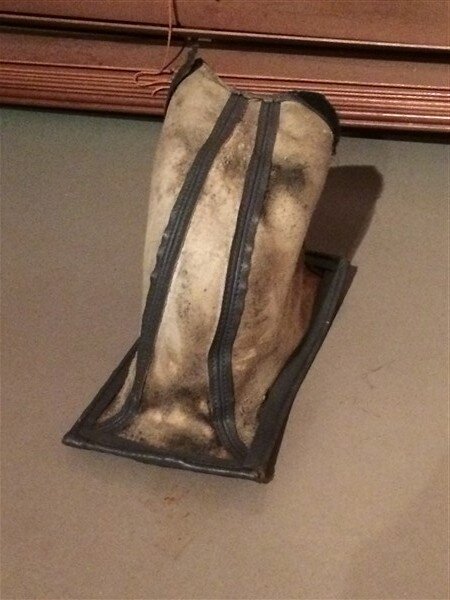

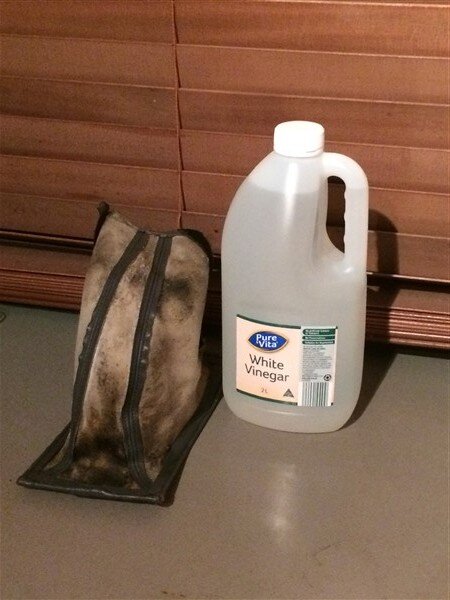

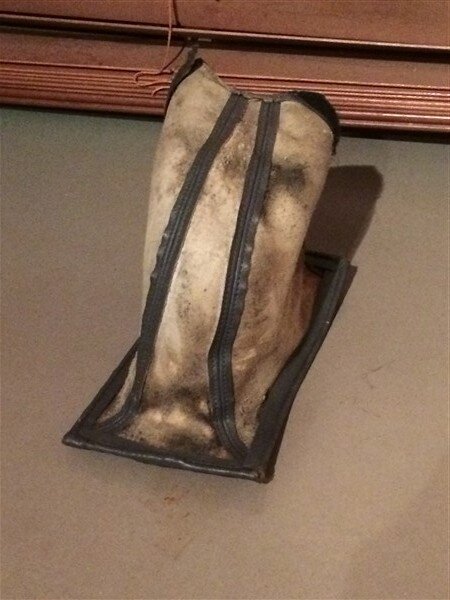

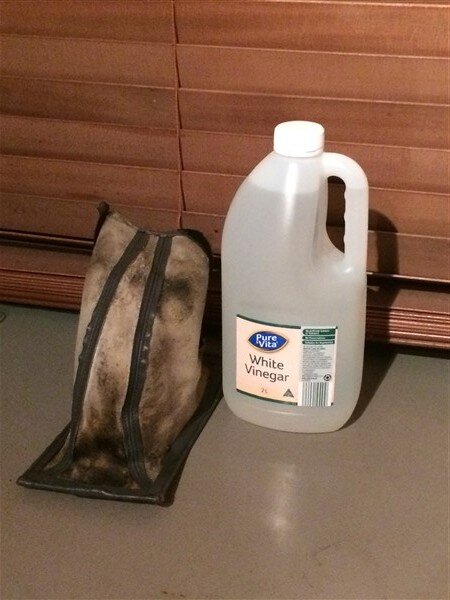

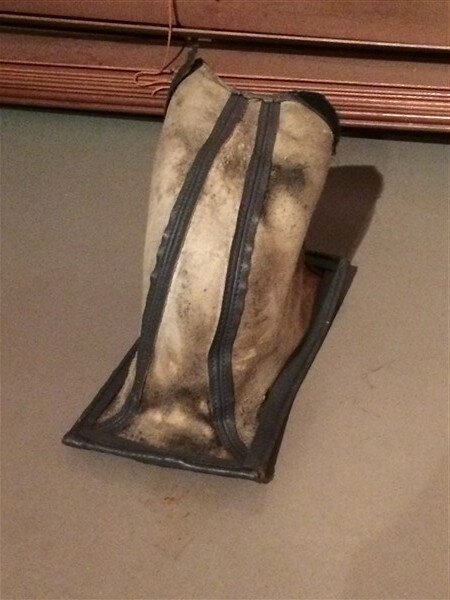

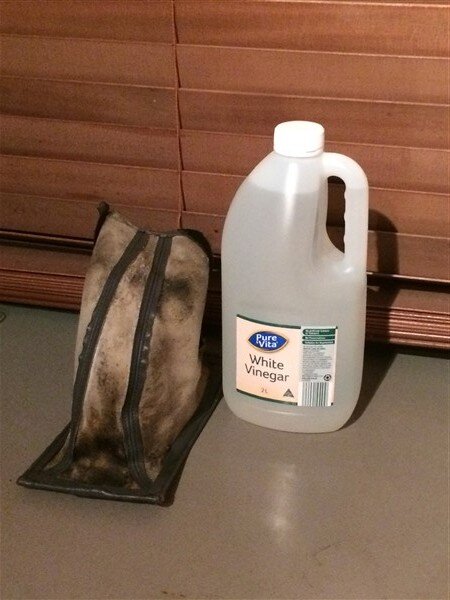

The faux leather hand brake cover I got from the KZJ78 was sadly a bit moldy.

So after discovering online that white vinegar is the best thing to treat/kill it with I gave it a good wipe with that and left it overnight to soak.

This morning I could fit it but I first I needed to decide whether or not to re-fit the rear heater.

Decided I would as it might be useful if the kids are cold one day, maybe after a trip to the beach, but were not, we can stay cool and just put the hot air on them.

So got it bolted in position along with the center console and hand brake cover.

Not sure if I will use these slightly crusty corroded looking pipes to connect it or not, tempted to just run rubber hoses instead then it might be more reliable.

I will need to clean up and fit this box though next.

As it is far too low to be of any use as an arm rest I'm thinking of trying to mount fold up arm rests directly to the seats. Like the early range rovers and some of the later Transit vans.

Oh one more thing I went picking last weekend.

I went back and bought a load more bits off that KZJ78.

If I had of had room I would have bought the whole thing and just parked it up, but sadly I dont have land yet.

The guy let me use his hoist and tools which was very kind of him.

Got a good trailer load.

I will sell some of it to make some money and keep some of it as spares for my 78.

Cant decide whether to keep the valuable R151 gearbox or not, I've currently got 4 and only need 2 for my 70's and I want to keep one as a spare.

Does anyone know if the KZJ78 had different gear ratios in the gearbox compared to the LJ70's?

I did some searching but couldnt find out.

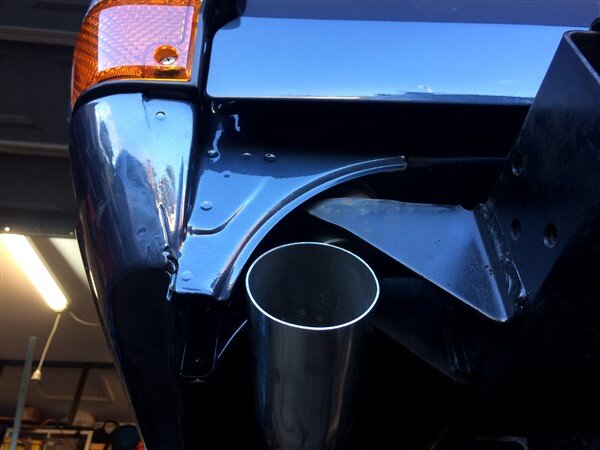

This is the box.