BRE Fabrications LTD

Well-Known Member

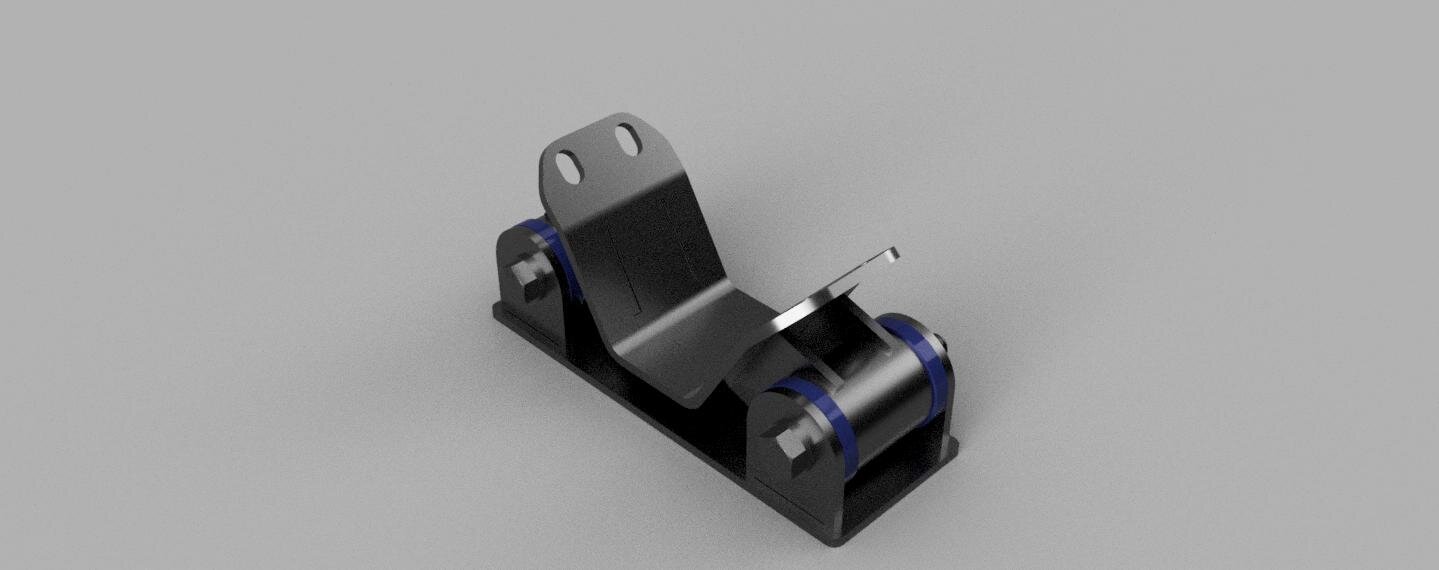

Well I have the design for the mounts nailed down, just sorting out some laser cutting and then it'll be time to make em.

This is the idea (blatantly copied from the inter web)

Sent from my iPhone using Tapatalk

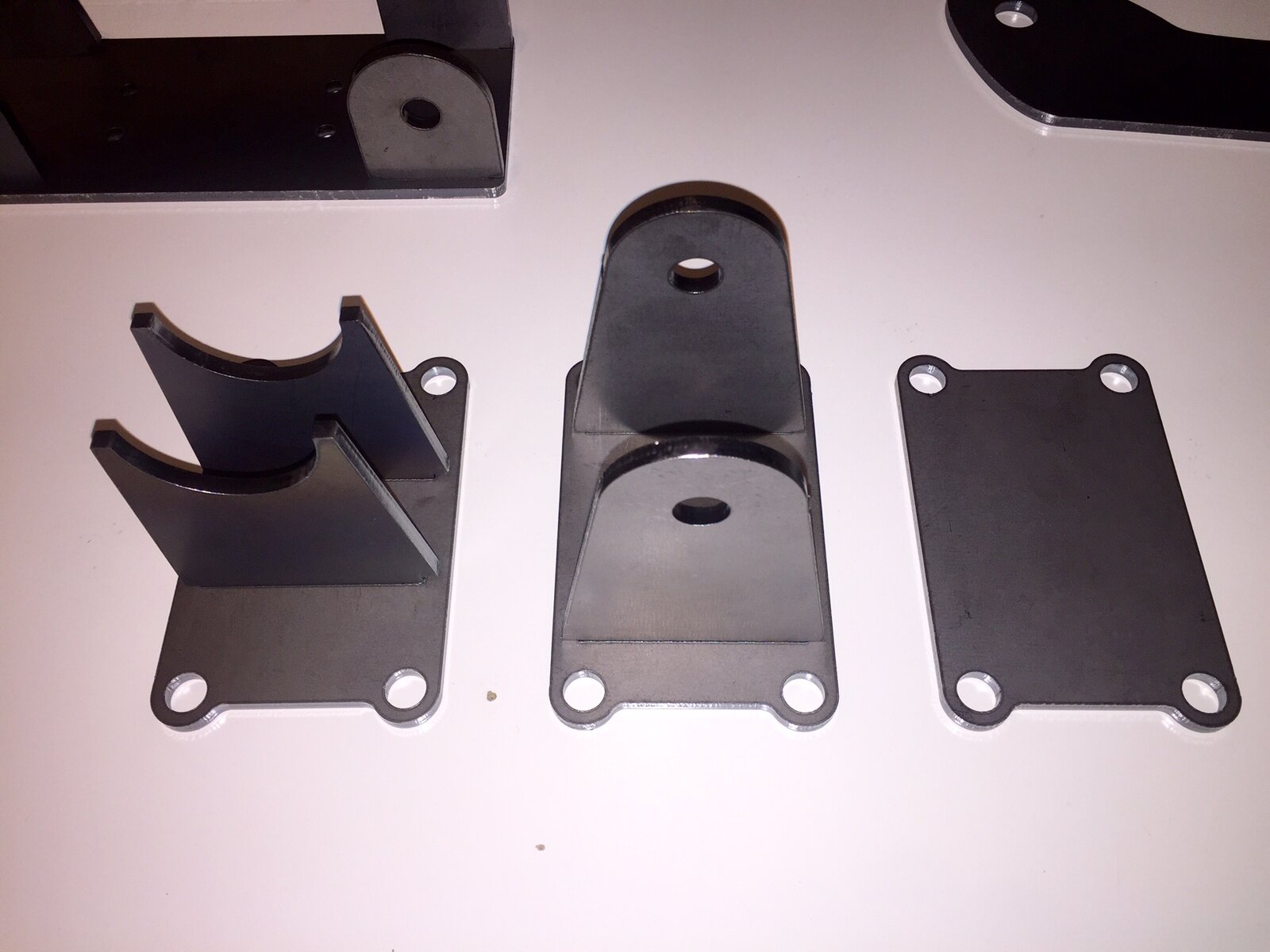

This is the idea (blatantly copied from the inter web)

Sent from my iPhone using Tapatalk