BRE Fabrications LTD

Well-Known Member

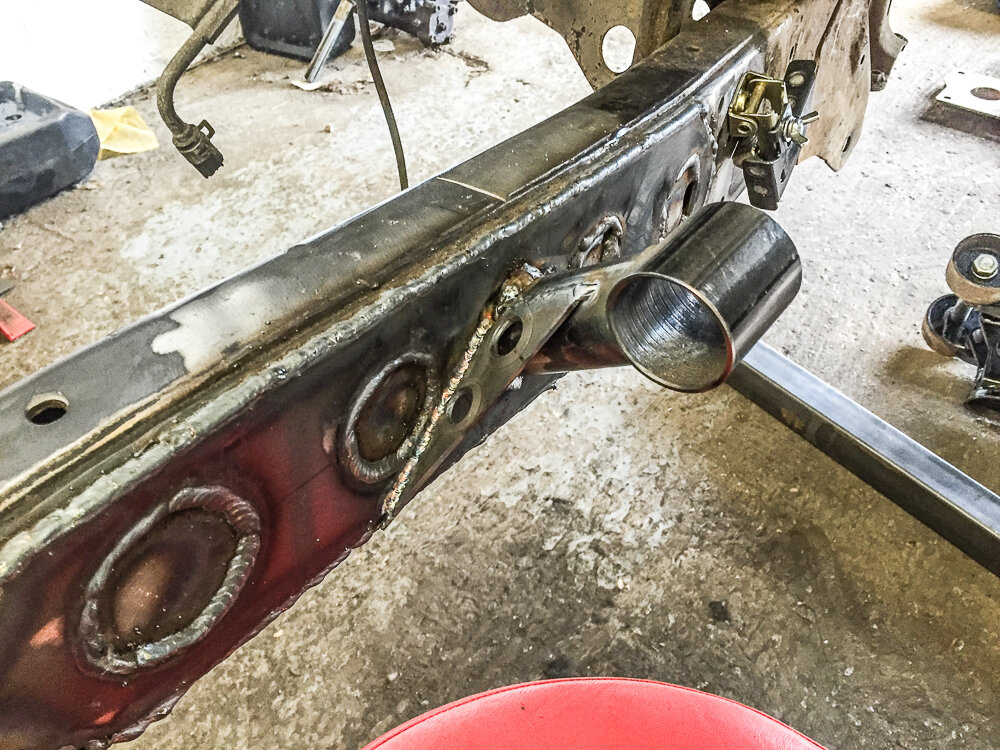

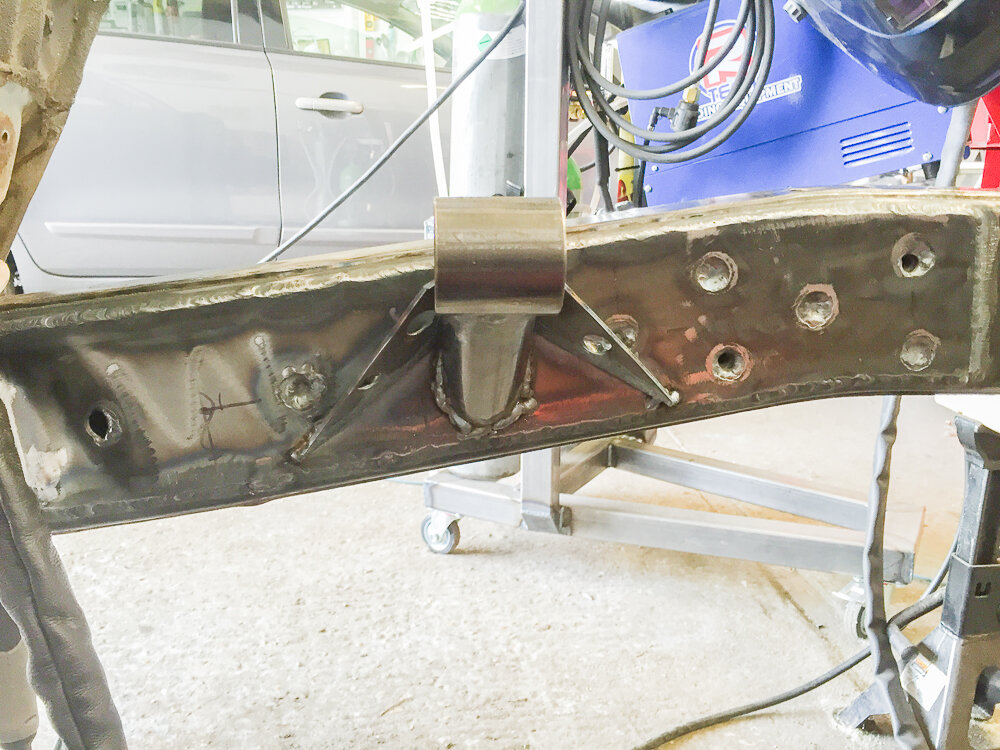

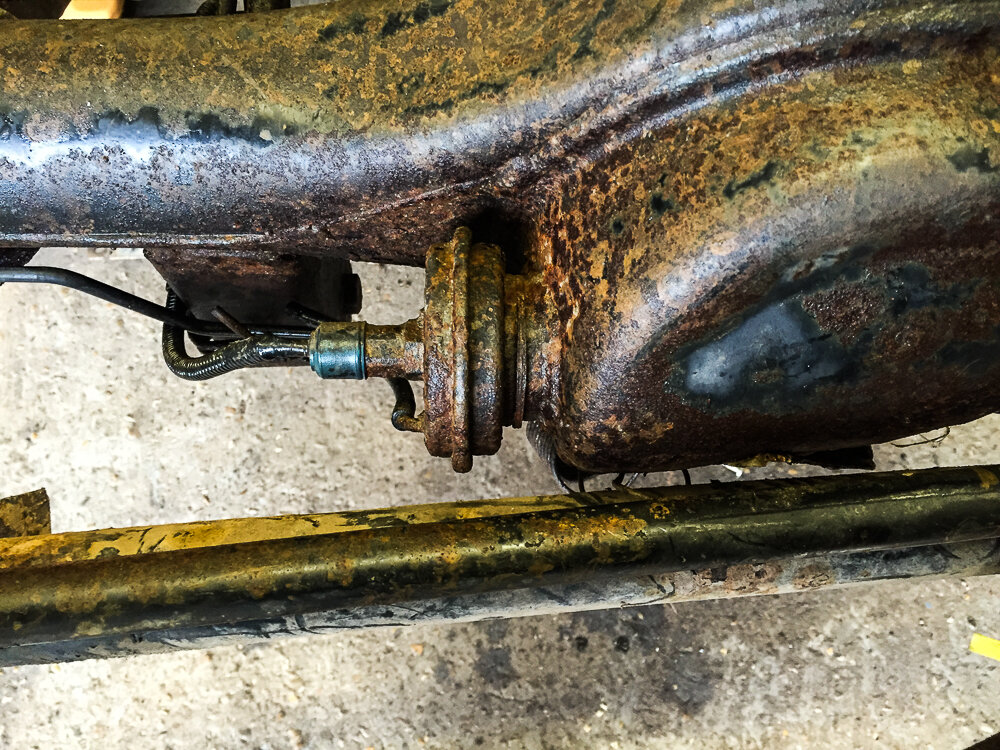

Looks good so far but ideally you shouldn't make the plates square/rectangle as the heat affected zone is running in a straight line vertical through the chassis.

I'm sure they will be fine in this instance but if you need to plate the chassis for any other mounts etc. a stronger way would be how they have done it below.

(Search on Google images for "Chassis Fish Plates ")

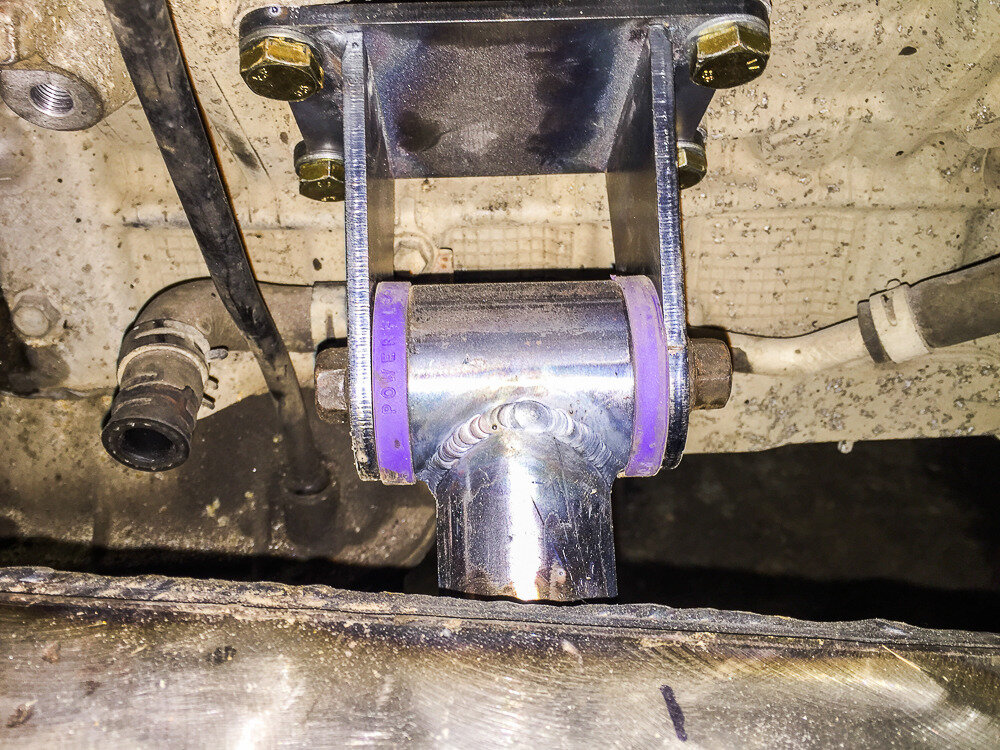

View attachment 99027

Also having bigger holes helps as you can get a longer bead of weld in there.

Get yourself a TIG Finger then you can rest your hand right next to where you are welding. I got one for my TIG test and it was a huge help!

http://www.ebay.co.uk/itm/Tig-Finge...hash=item339aeb9f97:m:m-15aA9j2ABE4c2USjn3l9w

MIG will obviously be a lot quicker but it will be no where near as strong as TIG, as with MIG you arnt getting 100% fusion like you are with TIG.

Also unless you are turning the chassis on its side for welding its also going to be tricky to get perfect welds with the MIG in the vertical up and over head positions, where as TIG seems to be almost as easy in those positions as the horizontal position, as gravity doesnt seem to affect the weld pool in the same way as it does MIG.

So my advice would be to get a TIG finger and weld the plates on with the TIG.

Thanks mate.

Hey ben,

good tip regarding the fish plates, I hadn't thought about that. Thanks.

I have have a Tig finger which has helped. Think I just need more practic.