- Joined

- Oct 13, 2010

- Messages

- 6,058

- Country Flag

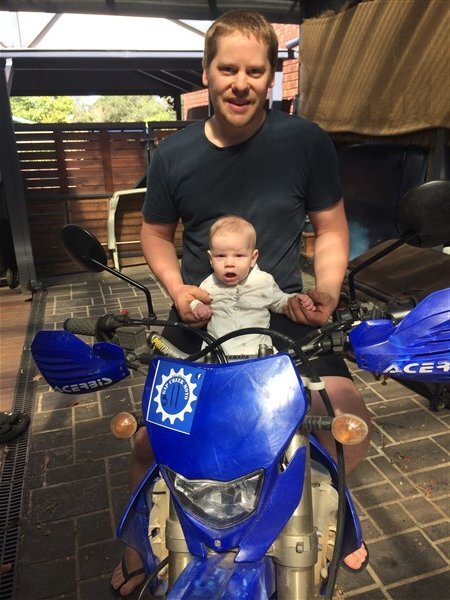

Ha, little helper will be usefull in a few years time

Can you do anything about that carport roof ? A hinged flap or something so you don't need to take rack off each time.

I can't fit my hilux into my garage, even with stuff off the roof it Is 1cm too high

I have been thinking of building a carport next to garage, but there is a 5m x 2.5m shed in the way, I don't want to take the shed down, wondering if I can drag it to a new position to one side if I empty it...without wrecking it

Yeah I cant wait until hes old enough to help me with stuff!

Sadly I cant do anything about the car port height issue as its the bottom of one of the trusses that is too low.

If we bought the place I would pull the whole car port down and raise it by a foot!

geez Ben,I thought you would struggle with the weight of the containers.

You better buy a truck for the next shift.Good luck mate.

I never want to move again mate, its been the hardest move yet!

Well Ben, think of the gym fees you’ve saved

Good to see Sam in on the action, even though he was sleeping on-the-job

With the pit, you might get away with using the aqua-vac thingy, if you check it on a regular basis. But, if it fills more rapidly, an electric submersible will do the job in a jiffy, and (here at least) they are very reasonably priced. You’d only need a small capacity one for the volume you have there. The integral sump will help a lot to speed up drying out, because you’ll get the water level lower than if was just a flat level floor.

Pity about the height deficiency, you’ll think of something, that’s for certain!

It’s suggested that moving house is more stressful than a divorce, and I’ve experienced both, so clearly, you’re passed the worst of it mate, job well done

Yes a submersible pump will be getting purchased shortly. Their so cheap I would be crazy not to. Thanks mate, it certainly was stressful especially with a baby!

Ben I really enjoyed reading and seeing photos about the move down. Love that you moved into your new garage quarters so quick!!!

Thanks mate, glad you enjoyed it.

Excellent stuff and interesting to follow. Where did you move to?

Thanks mate.

After 2 years living in Queensland we decided we preferred life in Melbourne so moved back.

Glad you've completed the move without too many troubles Ben. It did look like hell of a lot of work though! Pretty shitty for the previous tenants (or owners?) to dump all of their rubbish in the pit though. Did you ask them to sort it out for you or just get on with cleaning up their mess?

Thanks mate.

We're only renting and I didnt want to ask about clearing the pit out encase they said no.

Maybe it was a legal requirement/insurance requirement that it had to be filled in.

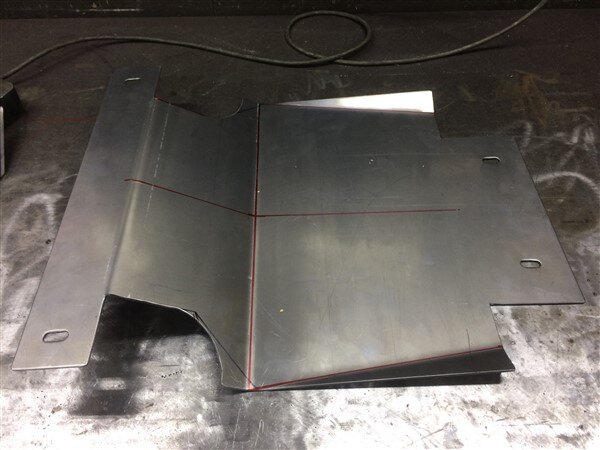

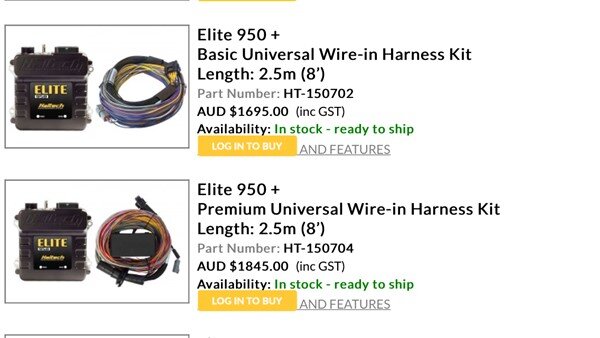

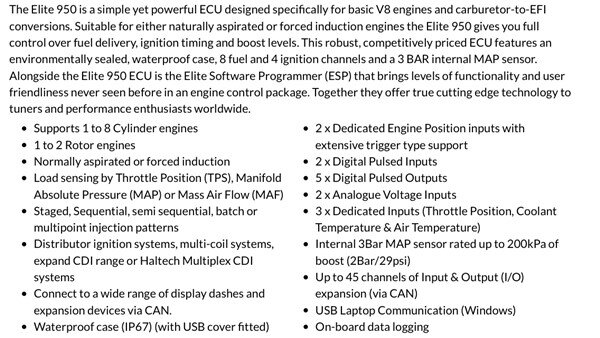

I actually almost abandoned the whole project half way through filling the first trailer, as not only was it hard dirty work, but I've got access to a hoist at work that I can use. The only reason I kept going is so I can build the 3" stainless steel mandrel bent exhaust system on LJ and really take my time with it and a pit will just make it so much easier!

Sam is the spit of you Ben.......

Getting that pit sorted is going to be a major plus for you in the future lad. Now that it's empty and clean if I were you I'd get my hands on a pump and fit it in semi permanently encase the pit floods in the winter. It would take a long time to vacume a lot of water out where as a pump would have you sorted in no time at all. That workshop is every man's dream....... I'm jealous lol. Looking forward to lj70 being completed now

Thanks mate.

Poor bugger has certainly inherited my looks!

Yeah I will definitely get a pump mate.

It is a great space and will make finishing LJ so much easier.

Same here, Mini me.

Thing is, I can also see Bec in him too.

I reckon he'll be taking after his pop. Might even out-fabricate him when the time comes.

He is my replacement so I really hope he does become better than me!

I really hope he will be interested in doing boy things and making and fixing things, if so I will teach him everything I know!

I would love for him to be driving and welding by 12!