Don't like the adverts? Click here to remove them

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

LJ70 Build Thread!

- Thread starter Ben

- Start date

- Joined

- Oct 13, 2010

- Messages

- 6,058

- Country Flag

Thanks guys.

It was a great birthday!

Had a bit of news this week from my old boss........................

The world record attempt at being the first solar powered vehicle to cross the Simpson Desert has been pushed back to next year due to all the rain they have had lately in central Australia.

It actually suits us better as it was going to be very close to the wedding.

It was a great birthday!

Had a bit of news this week from my old boss........................

The world record attempt at being the first solar powered vehicle to cross the Simpson Desert has been pushed back to next year due to all the rain they have had lately in central Australia.

It actually suits us better as it was going to be very close to the wedding.

- Joined

- Oct 13, 2010

- Messages

- 6,058

- Country Flag

I got a bit of work done on LJ over the last couple of days.

I got the new rear door and sun shade outside yesterday and sanded and cleaned them ready for paint.

The sun shade came fitted to RJ when I bought it, but it had to go as it prevents the screen from being folded down.

I wasnt sure whether I liked it or not, but decided I'd get it painted and see what it looks like on LJ.

Got them both in primer.

Followed by a few coats of Midnight Blue.

This morning they were nice and dry.

Not a perfect paint finish but at least they will match the rest of the car!

Removed the swing away wheel carrier arm.

I will loose my gas stove storage but I think thats a fair trade off for how much more practical the car will be with the spare back on the door.

I started removing the old door.

It hadnt rained for a few weeks but was scheduled to today, but at least the next week looks perfect!

Thankfully I had the rear awning or I dont think I would have been able to get much done today as it rained from 11am onwards.

New door bolted on.

Fitted my old window.

Bolted on the spare wheel bracket.

And got the spare mounted.

Pulled the old bumper off.

The new one is about 1/4 of the weight.

Had to remove the last section of exhaust so I could get the new bumper on. It needs some work doing to it as I need to add a towbar/receiver hitch to it and I want to add my lights and trailer socket, then I want to get it shot blasted and powder coated.

And finally I got the sun shade bolted on. Found standing up through the open sun roof was the easiest way, even though it was raining quite heavy.

Will get some better pics of the sun shade next time the sun is out. But I think I like it.

So the big job now is to modify the rear bumper and exhaust.

I'm hoping the new bumper will improve LJ and make it more practical for the sort of family camping trips/light off roading I'm doing.

At some point I will build a Jimny comp truck for silly stuff and thats what I'm keeping my 37" tyres for now I no longer run them on LJ.

I got the new rear door and sun shade outside yesterday and sanded and cleaned them ready for paint.

The sun shade came fitted to RJ when I bought it, but it had to go as it prevents the screen from being folded down.

I wasnt sure whether I liked it or not, but decided I'd get it painted and see what it looks like on LJ.

Got them both in primer.

Followed by a few coats of Midnight Blue.

This morning they were nice and dry.

Not a perfect paint finish but at least they will match the rest of the car!

Removed the swing away wheel carrier arm.

I will loose my gas stove storage but I think thats a fair trade off for how much more practical the car will be with the spare back on the door.

I started removing the old door.

It hadnt rained for a few weeks but was scheduled to today, but at least the next week looks perfect!

Thankfully I had the rear awning or I dont think I would have been able to get much done today as it rained from 11am onwards.

New door bolted on.

Fitted my old window.

Bolted on the spare wheel bracket.

And got the spare mounted.

Pulled the old bumper off.

The new one is about 1/4 of the weight.

Had to remove the last section of exhaust so I could get the new bumper on. It needs some work doing to it as I need to add a towbar/receiver hitch to it and I want to add my lights and trailer socket, then I want to get it shot blasted and powder coated.

And finally I got the sun shade bolted on. Found standing up through the open sun roof was the easiest way, even though it was raining quite heavy.

Will get some better pics of the sun shade next time the sun is out. But I think I like it.

So the big job now is to modify the rear bumper and exhaust.

I'm hoping the new bumper will improve LJ and make it more practical for the sort of family camping trips/light off roading I'm doing.

At some point I will build a Jimny comp truck for silly stuff and thats what I'm keeping my 37" tyres for now I no longer run them on LJ.

Last edited:

I hope you find the sunshade a practical solution, Ben.

Here the lanes/tracks that I run on are very overgrown and I think low branches would soon have that off. Your tracks, from what I've seen, are more open and less prone to damaging it.

Nice work anyway, the new bumper looks good

Here the lanes/tracks that I run on are very overgrown and I think low branches would soon have that off. Your tracks, from what I've seen, are more open and less prone to damaging it.

Nice work anyway, the new bumper looks good

Paddler Ed

Well-Known Member

We've just come back from out west (SW of Nyngan) and a lot of stuff out that way runs a shade strip like that; they're also often seen on old peoples cars... now that sounds negative, but you only get old by doing things right on the whole... so they must be doing something right! I reckon as well that it'll cut down glare onto the dashboard.

We've just come back from out west (SW of Nyngan) and a lot of stuff out that way runs a shade strip like that; they're also often seen on old peoples cars... now that sounds negative, but you only get old by doing things right on the whole... so they must be doing something right! I reckon as well that it'll cut down glare onto the dashboard.

My experience in the U.K. is that "glare" is something you only get from a pedestrian when you don't stop at the zebra!

Lads, ED means the bright stuff that comes from that shiny thing in the sky once or twice a year...

Runs and hides.....

Don't like the adverts? Click here to remove them

Plattapuss

New Member

- Joined

- Oct 29, 2016

- Messages

- 1

- Country Flag

G'day ben,

Just read your whole thread from beginning to end (yes it did take agers). Cheers for taking the effort to post in such detail with lots of photos. Keen to see what you do to a 79 when you get it.

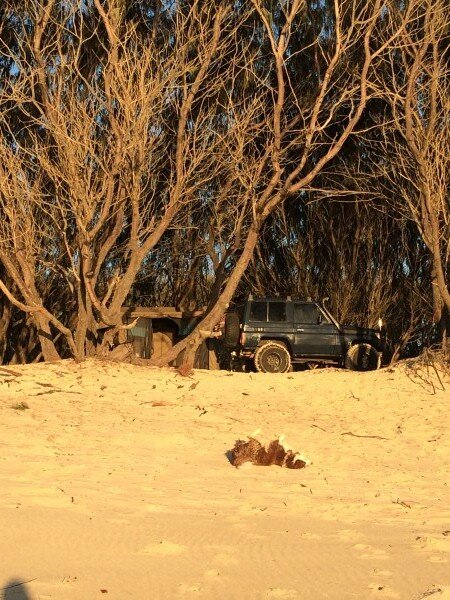

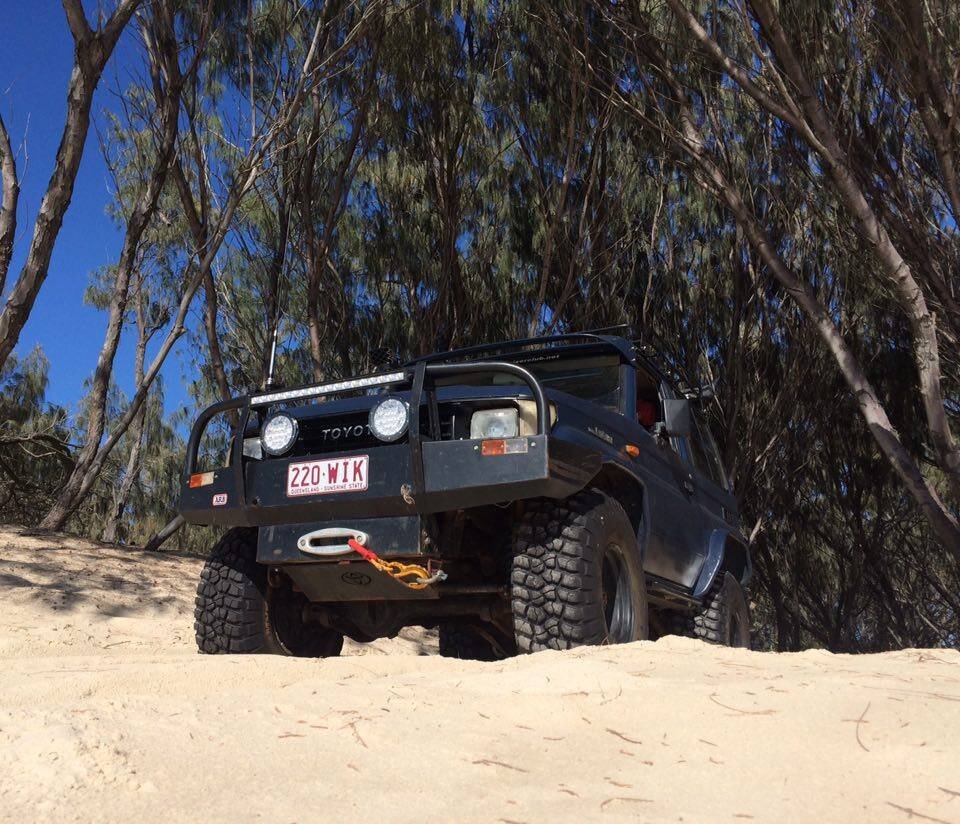

Hers a pic of my hzj75 for ya,

Just read your whole thread from beginning to end (yes it did take agers). Cheers for taking the effort to post in such detail with lots of photos. Keen to see what you do to a 79 when you get it.

Hers a pic of my hzj75 for ya,

- Joined

- Oct 13, 2010

- Messages

- 6,058

- Country Flag

Thanks guys.

Going to finally test the old persons sunscreen out this week!

Wow! Good effort reading the whole thing!

You're welcome mate, glad you enjoyed it!

Love you're 75! Looks very smart!

Must get across to WA one day!

Cant wait to get a 79, will be something really special when I'm done with it!

Going to finally test the old persons sunscreen out this week!

G'day ben,

Just read your whole thread from beginning to end (yes it did take agers). Cheers for taking the effort to post in such detail with lots of photos. Keen to see what you do to a 79 when you get it.

Hers a pic of my hzj75 for ya,

View attachment 108522

Wow! Good effort reading the whole thing!

You're welcome mate, glad you enjoyed it!

Love you're 75! Looks very smart!

Must get across to WA one day!

Cant wait to get a 79, will be something really special when I'm done with it!

- Joined

- Oct 13, 2010

- Messages

- 6,058

- Country Flag

OK Update Time!

As I'm slowly putting LJ back to being a bit more standard, I decided to refit the rear badges.

Had to find some old pics to work out where they used to go.

Stuck them back on with 3m double sided foam tape.

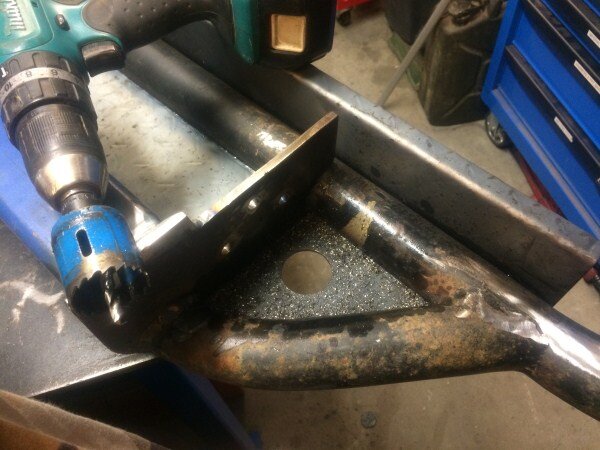

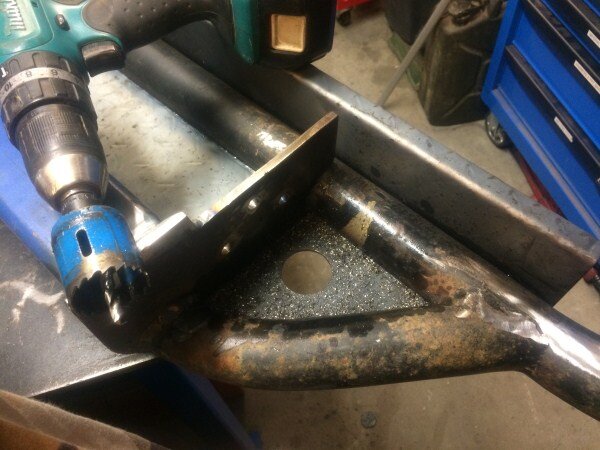

I've been doing lots of work on the rear bumper/bar.

So this is where we were up to at the last update, with the second hand rear bar.

I picked up some steel for the towbar I nedeed to add to it.

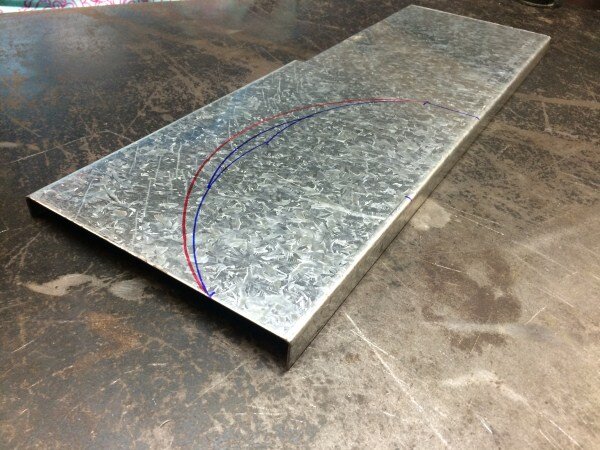

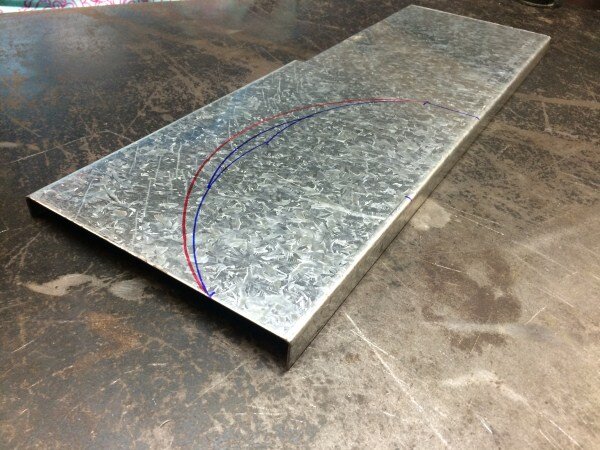

And some 2mm checker plate that I had cut and folded.

Designed the plates that would bolt the whole thing to the chassis.

Tack welded the 2 8mm thick plates together.

Got them on the drill press and put a 48mm hole saw through them.

Used some punches to work out where my mounting holes needed to be on my cardboard templates.

Transferred those marks onto my steel.

Center punched and drilled them.

Bolted them on.

Cut the old brackets off the rear bar.

Tack welded the piece of 65mm box section, tow bar steel between my chassis plates.

Bolted that back onto the chassis and brought LJ round to the garage to tack weld the rear bar onto the chassis plates.

Got it on the bench to full weld it.

Test fitting back on the car.

Decided the bar would look better filled in with checker plate and it would also tie in with my rock sliders that have checker plate on the top.

The piece I ordered was too wide so had to cut it down.

Cut it to fit inside the tube work.

Clamped and it in position.

Dragged the welder outside.

And tack welded it in position.

Pulled the bar off, flipped it over and started cutting in the receiver hitch for the towbar.

Drilled a 16mm hole through the receiver section.

Cut it to length on my cold cut saw.

Decided to fully TIG weld the top piece of checker as I knew it would be far neater than using a MIG as I could just fusion weld the checker to the tube without needing to even add any filler rod.

We have a huge workshop at work for woodwork and metal work with every machine imaginable and my boss said I can come in and use what I like, when I like!

So I took the bar in to use the MIG.

Brought it home and drilled some holes through with a hole saw for the rear LED lights.

Cut, drilled and welded on some mounting tabs for them.

Welded on some cut chain links for the mudflaps.

Cut some strips of alluminium checker plate.

Bolted them to some thick rubber I cut for the mudflaps along with some chain.

Needed to clean the bar up and get it ready for paint next, using the 3 Makita's.

Hung the bar up on a ratchet strap between LJ and the fence.

Found some black paint.

Sprayed it.

Bolted it on along with my rear swivel recovery point and LED lights.

Mudflaps next.

Chains keep them away from the tyres.

Then when we go off road they simply get clipped up higher out of the way.

The rear bar isnt finished, I need to add more steel to brace the towbar and side wings back to the chassis, then I want it shot blasting and powder coating.

So why paint it and fit it I hear you ask...................

Well the wedding is now less than 2 weeks away and as we wont be going on a honey moon till next year as we have lots of international friends and family over for the wedding, it wont be practical to go away straight afterwards.

So were going on a mini pre-moon!

Going to jump on a ferry and take LJ to one of the islands for a few days of beach camping and relaxing!

So I had to get the rear bar fitted so we could have those all important mudflaps fitted to avoid any hassle from the boys in blue!

Not too much other stuff has been happening.

Been taking Lexi to the beach every weekend.

We bought a new lounge suite last weekend and foolishly trusted Lexi with the old one in her area.

It lasted 2 days until I got home to this.

Now granted it was hideous anyway but I was keeping it as it folds out into a double bed.

Oh well...............one less thing to move next year when we buy some where.

I bought another new tool!

Trying to build up my collection now as they come up cheap on Gumtree rather than waiting until I desperately need one for a job.

Purposely steered clear of cordless as I know which one will still be working in 30 years time!

I wanted an edging tool to neaten up the edges of my lawns where it meets the concrete.

But I couldnt justify paying the stupid prices for the proper tool, when they were selling them for 2-3 times the price of a spade.

So I decided to knock one up out of some scrap I had in the garage.

Found and marked a piece of folded galvanized sheet steel.

Cut it out and cut and notched some 25mm tube.

Welded all the bits together.

A quick spray silver and it was done!

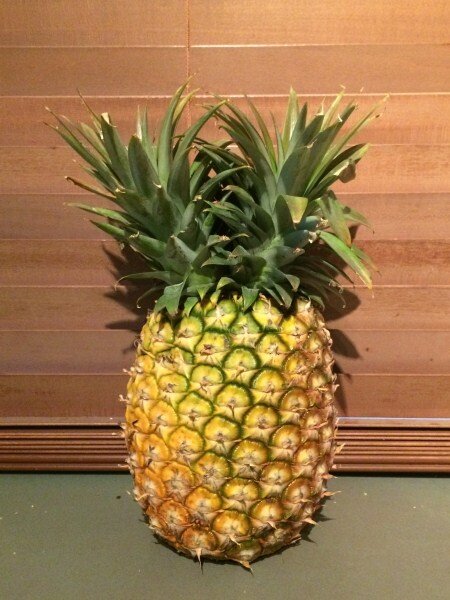

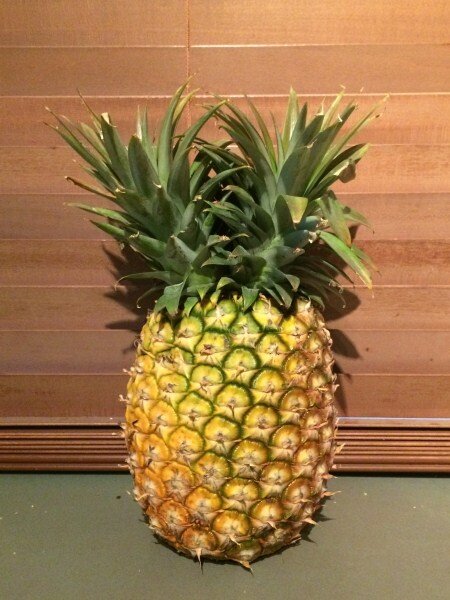

We were looking at some pineapples at a market and I spotted one with a double head on it and knew I had to have it! Should make a cool plant!

I've plated that out now in some old paint pots as I couldnt justify the price of large, proper pots.

The fruit and veg garden is really starting to come back alive now as the weather warms up for Summer.

I've got lots of tomato seedlings growing in pots, from some seeds I bought.

To get a head start I also bought 2 different tomato plants a few weeks ago and they are now starting to produce lots of tomatoes.

The strawberries are also taking off.

This side the Rosemary, Basil, Mint and Thyme are all doing well and the Parsnip seeds I planted are starting to sprout too.

The original pineapple top I planted is continuing to grow bigger and bigger, so I'm hopeful fruit wont be too far away.

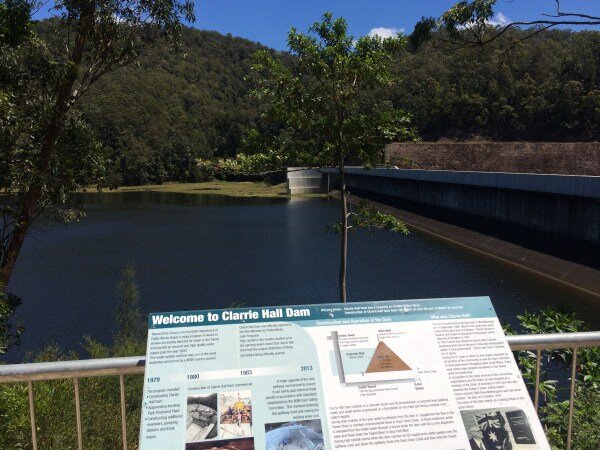

I've been getting out for more rides on the bike!

Got out with 2 of my mates for a ride last week.

Headed out through the hinterland and down to Nimbin to one of my favorite cafes for a spot of lunch, complete with hippy entertainment.

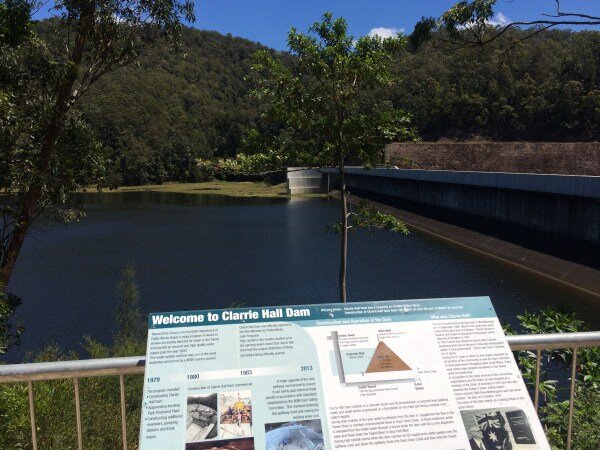

Stopped at a reservoir for a look on the way back.

Was a great day!

I recently got 160kmh out of the bike (on private property of course). I was pretty impressed with that and it felt like it had a bit more left, but on knobbly tyres and with no fairing it didnt feel too safe so I will stick to 100-130 in future.

As I'm slowly putting LJ back to being a bit more standard, I decided to refit the rear badges.

Had to find some old pics to work out where they used to go.

Stuck them back on with 3m double sided foam tape.

I've been doing lots of work on the rear bumper/bar.

So this is where we were up to at the last update, with the second hand rear bar.

I picked up some steel for the towbar I nedeed to add to it.

And some 2mm checker plate that I had cut and folded.

Designed the plates that would bolt the whole thing to the chassis.

Tack welded the 2 8mm thick plates together.

Got them on the drill press and put a 48mm hole saw through them.

Used some punches to work out where my mounting holes needed to be on my cardboard templates.

Transferred those marks onto my steel.

Center punched and drilled them.

Bolted them on.

Cut the old brackets off the rear bar.

Tack welded the piece of 65mm box section, tow bar steel between my chassis plates.

Bolted that back onto the chassis and brought LJ round to the garage to tack weld the rear bar onto the chassis plates.

Got it on the bench to full weld it.

Test fitting back on the car.

Decided the bar would look better filled in with checker plate and it would also tie in with my rock sliders that have checker plate on the top.

The piece I ordered was too wide so had to cut it down.

Cut it to fit inside the tube work.

Clamped and it in position.

Dragged the welder outside.

And tack welded it in position.

Pulled the bar off, flipped it over and started cutting in the receiver hitch for the towbar.

Drilled a 16mm hole through the receiver section.

Cut it to length on my cold cut saw.

Decided to fully TIG weld the top piece of checker as I knew it would be far neater than using a MIG as I could just fusion weld the checker to the tube without needing to even add any filler rod.

We have a huge workshop at work for woodwork and metal work with every machine imaginable and my boss said I can come in and use what I like, when I like!

So I took the bar in to use the MIG.

Brought it home and drilled some holes through with a hole saw for the rear LED lights.

Cut, drilled and welded on some mounting tabs for them.

Welded on some cut chain links for the mudflaps.

Cut some strips of alluminium checker plate.

Bolted them to some thick rubber I cut for the mudflaps along with some chain.

Needed to clean the bar up and get it ready for paint next, using the 3 Makita's.

Hung the bar up on a ratchet strap between LJ and the fence.

Found some black paint.

Sprayed it.

Bolted it on along with my rear swivel recovery point and LED lights.

Mudflaps next.

Chains keep them away from the tyres.

Then when we go off road they simply get clipped up higher out of the way.

The rear bar isnt finished, I need to add more steel to brace the towbar and side wings back to the chassis, then I want it shot blasting and powder coating.

So why paint it and fit it I hear you ask...................

Well the wedding is now less than 2 weeks away and as we wont be going on a honey moon till next year as we have lots of international friends and family over for the wedding, it wont be practical to go away straight afterwards.

So were going on a mini pre-moon!

Going to jump on a ferry and take LJ to one of the islands for a few days of beach camping and relaxing!

So I had to get the rear bar fitted so we could have those all important mudflaps fitted to avoid any hassle from the boys in blue!

Not too much other stuff has been happening.

Been taking Lexi to the beach every weekend.

We bought a new lounge suite last weekend and foolishly trusted Lexi with the old one in her area.

It lasted 2 days until I got home to this.

Now granted it was hideous anyway but I was keeping it as it folds out into a double bed.

Oh well...............one less thing to move next year when we buy some where.

I bought another new tool!

Trying to build up my collection now as they come up cheap on Gumtree rather than waiting until I desperately need one for a job.

Purposely steered clear of cordless as I know which one will still be working in 30 years time!

I wanted an edging tool to neaten up the edges of my lawns where it meets the concrete.

But I couldnt justify paying the stupid prices for the proper tool, when they were selling them for 2-3 times the price of a spade.

So I decided to knock one up out of some scrap I had in the garage.

Found and marked a piece of folded galvanized sheet steel.

Cut it out and cut and notched some 25mm tube.

Welded all the bits together.

A quick spray silver and it was done!

We were looking at some pineapples at a market and I spotted one with a double head on it and knew I had to have it! Should make a cool plant!

I've plated that out now in some old paint pots as I couldnt justify the price of large, proper pots.

The fruit and veg garden is really starting to come back alive now as the weather warms up for Summer.

I've got lots of tomato seedlings growing in pots, from some seeds I bought.

To get a head start I also bought 2 different tomato plants a few weeks ago and they are now starting to produce lots of tomatoes.

The strawberries are also taking off.

This side the Rosemary, Basil, Mint and Thyme are all doing well and the Parsnip seeds I planted are starting to sprout too.

The original pineapple top I planted is continuing to grow bigger and bigger, so I'm hopeful fruit wont be too far away.

I've been getting out for more rides on the bike!

Got out with 2 of my mates for a ride last week.

Headed out through the hinterland and down to Nimbin to one of my favorite cafes for a spot of lunch, complete with hippy entertainment.

Stopped at a reservoir for a look on the way back.

Was a great day!

I recently got 160kmh out of the bike (on private property of course). I was pretty impressed with that and it felt like it had a bit more left, but on knobbly tyres and with no fairing it didnt feel too safe so I will stick to 100-130 in future.

Last edited:

Pat

Well-Known Member

- Joined

- Jun 3, 2014

- Messages

- 932

- Country Flag

Thanks guys.

Going to finally test the old persons sunscreen out this week!

Wow! Good effort reading the whole thing!

You're welcome mate, glad you enjoyed it!

Love you're 75! Looks very smart!

Must get across to WA one day!

Cant wait to get a 79, will be something really special when I'm done with it!

Hello Ben,I'm one of the old folks now,but all my life in everything I've driven

I like to sit high looking down on what's ahead and always have the interior sunvisor down.If you do that you are more comfortable when driving into the

sun.Regards and happy birthday.Pat

Nice work as usual Ben.

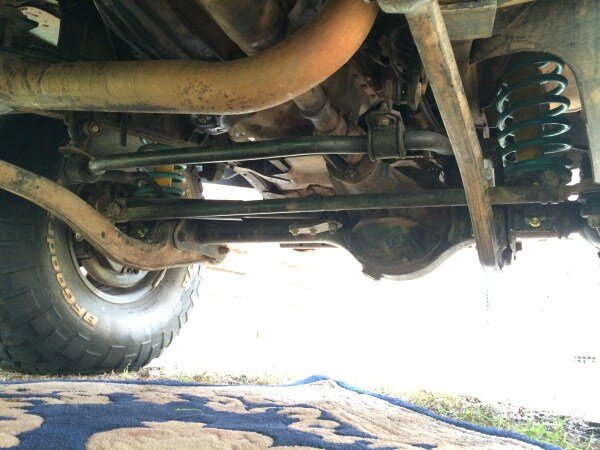

I started wondering if you intended some braces for the receiver, till you mentioned it toward the end of that part of the post.

As the receiver is the lowest point on the bumper, it's likely to get some hits on drop-offs and the occasional rock.

Mine does anyway and on a flat and level surface, unloaded, mine stands at 550mm off the ground, so it's surprising how it gets hits at all!

You likely know ARB products better than me but the rear carrier bumper for the 80 is a great example of ARB getting it right.

From underneath, you can see the shape of the brace, nice and wide, and thick steel, which makes for good protection from rocks.

Side on, you can see how it protects the receiver.

The drillings make it an ideal platform for safety chains and whatever else you may want to attach or mount.

Receivers are great, out can switch from tow ball to sankey, bike racks or other mountings. If the receiver is well braced, you can have up to a meter of protrusion, for bike racks holding 5 bikes on the horizontal (how many kids do you intend on having?

)

)

I started wondering if you intended some braces for the receiver, till you mentioned it toward the end of that part of the post.

As the receiver is the lowest point on the bumper, it's likely to get some hits on drop-offs and the occasional rock.

Mine does anyway and on a flat and level surface, unloaded, mine stands at 550mm off the ground, so it's surprising how it gets hits at all!

You likely know ARB products better than me but the rear carrier bumper for the 80 is a great example of ARB getting it right.

From underneath, you can see the shape of the brace, nice and wide, and thick steel, which makes for good protection from rocks.

Side on, you can see how it protects the receiver.

The drillings make it an ideal platform for safety chains and whatever else you may want to attach or mount.

Receivers are great, out can switch from tow ball to sankey, bike racks or other mountings. If the receiver is well braced, you can have up to a meter of protrusion, for bike racks holding 5 bikes on the horizontal (how many kids do you intend on having?

Last edited:

- Joined

- Oct 13, 2010

- Messages

- 6,058

- Country Flag

Before the trip I had to alter the very end section of exhaust as with the old rear bumper the exhaust came straight through it, but with the new one this wasnt possible.

A bit of cutting and welding later and it was done.

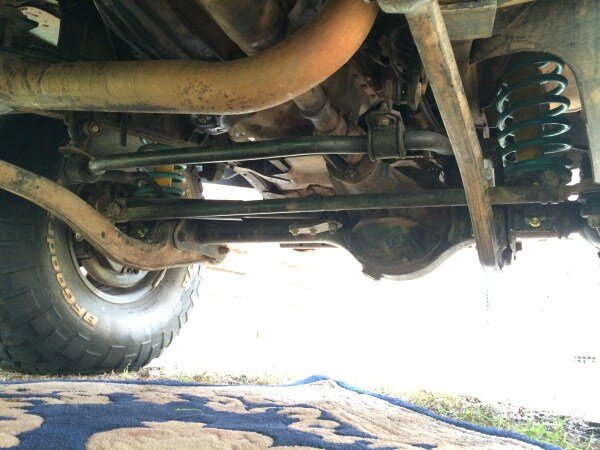

I also decided to refit the anti roll bar (or sway bar as their called here), to make LJ a bit more road friendly now I'm not driving anything too extreme.

It hadnt been fitted for 6 years so it took a little bit of working out to remember how it bolts on.

Then LJ was ready for the trip!

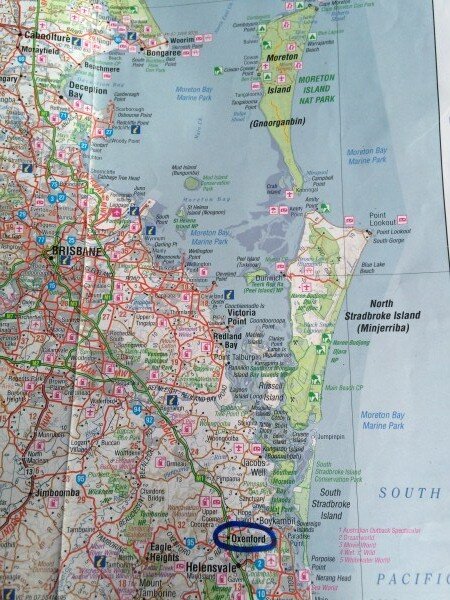

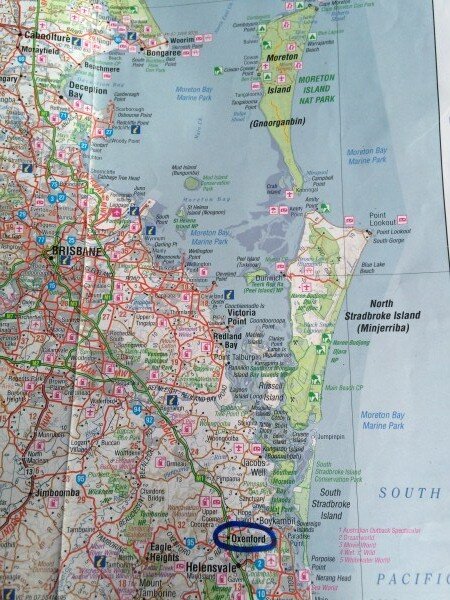

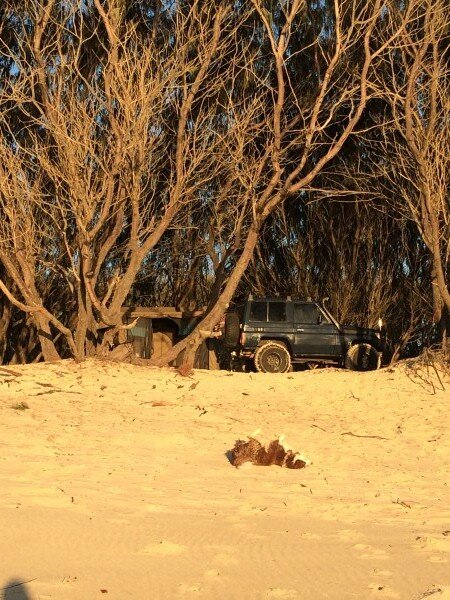

We wanted to go to Fraser Island or Moreton Island but nbeither of them allow dogs, unfortunately.

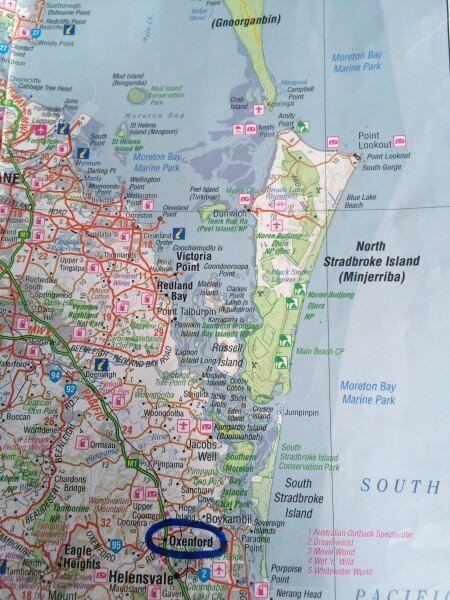

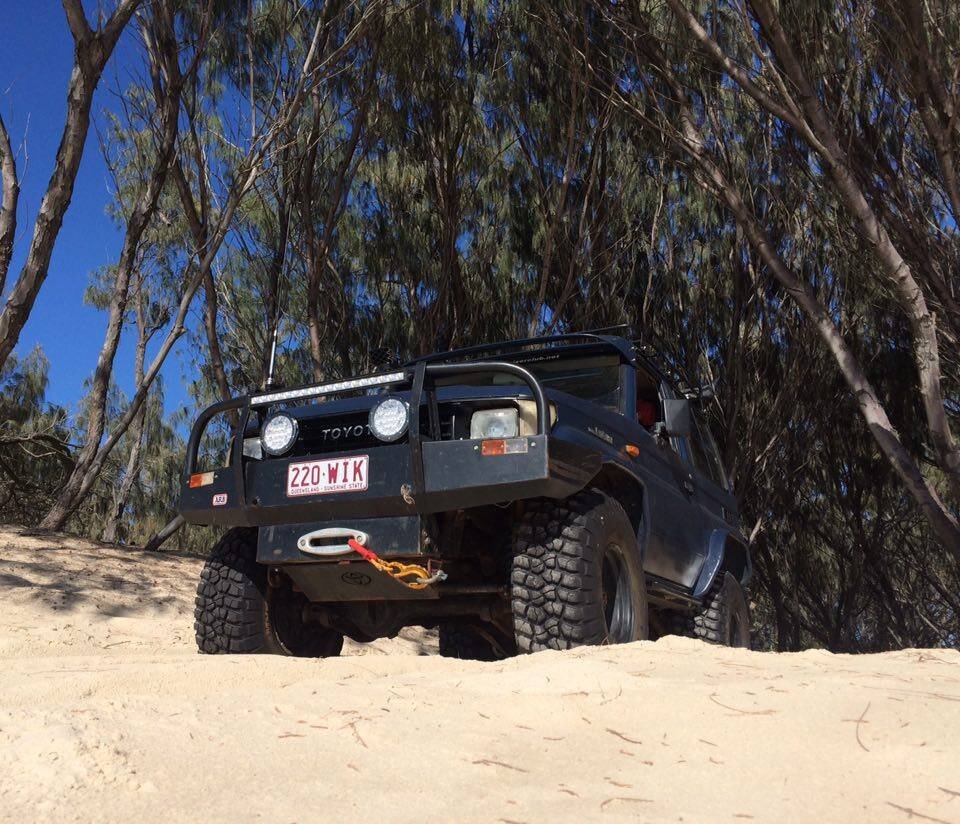

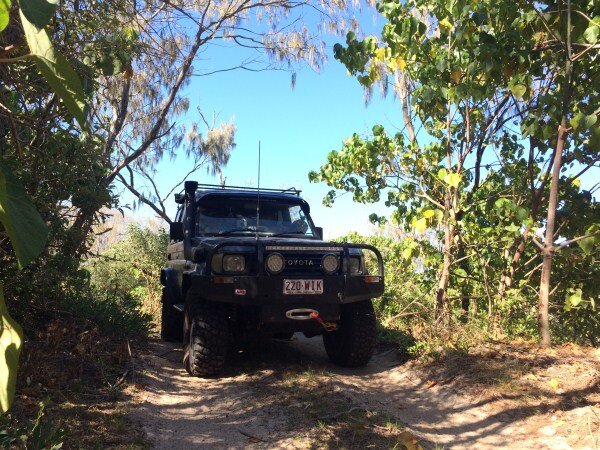

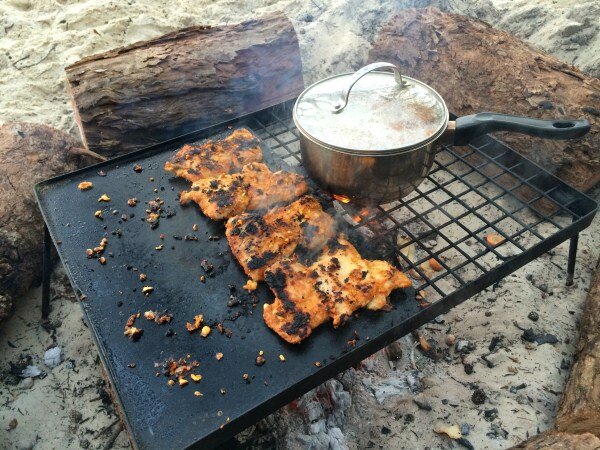

So we decided to head to North Stradbroke Island instead where dogs are welcome!

A quick look at the map reveals just how close it is to where we are in Oxenford.

Less than an hour to the ferry terminal.

We booked to stay at the Southern end of Main Beach on the East Coast, where the blue dot is.

We got LJ fully loaded on Monday morning.

Got to the ferry terminal just in time after some nightmare traffic on the motorway.

And we were soon on the boat.

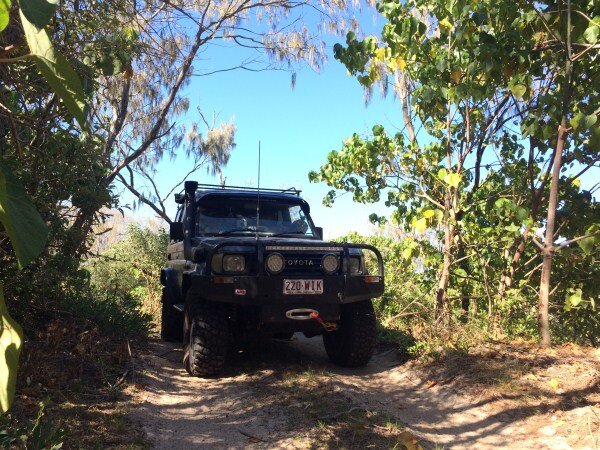

40 minutes later we were on the island and we were soon on the tracks.

Quite a cloudy overcast day but the beach and water still looked beautiful.

We headed South down Main Beach towards our camp.

The tracks leading into the camping areas behind the dunes were all marked with numbers.

These tracks were a lot of fun and quite challenging in places as they wound their way in and the dunes.

Not liking any of the first camping spots as they had no beach views, we rejoined the beach and headed further South.

We found a beautiful spot overlooking the beach and our nearest neighbor was a few k's away!

The fire was soon lit.

And Lexi was having the time of her life on the beach.

I cooked us dinner.

We spent the evening relaxing round the fire with a few cold ones.

The next morning the fire was soon re-lit and the kettle boiling.

While we tucked into the yummy sausage, egg, cheese and tomato sandwiches

Lexi started eating the fire wood!

I decided to drop the tyre pressures a bit more as I'd gone down to 20psi when we got off the ferry but found I was struggling for traction at times in the soft sand.

We hit the beach and headed North.

And soon found ourselves briefly back in civilisation.

We headed onto one of the beaches at the top of the island.

Sadly the tide was in so we couldnt drive along this beach just yet.

So we carried on exploring the top of the island.

We got a bit of rain and decided to head back to camp.

It brightened up a bit and we sat and had a few cold ones.

It had all been too much for Lexi who had a good sleep.

But not for too long.

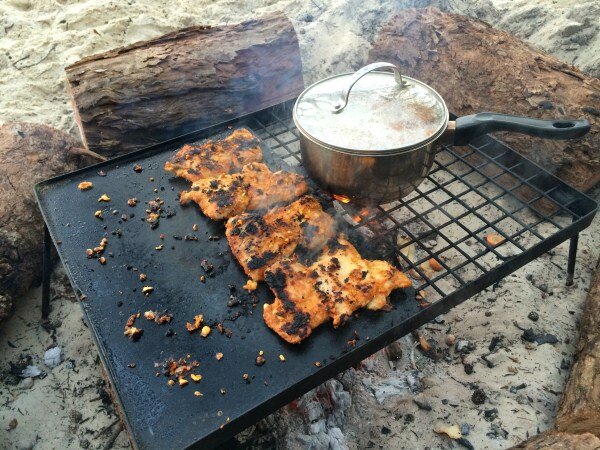

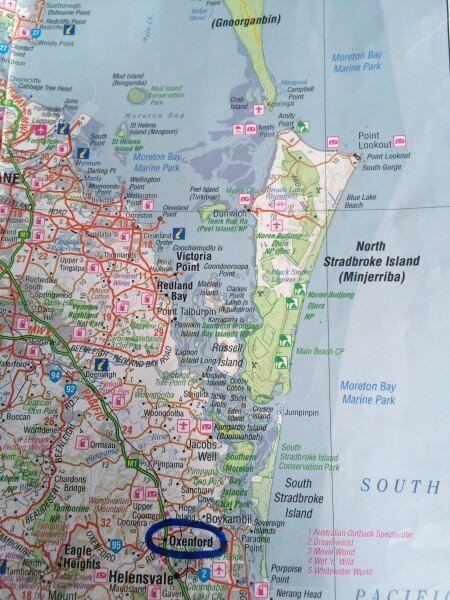

I got dinner on.

Chicken satay steaks and veggies.

We then relaxed round the fire with a few more cold ones.

The next morning we awoke to beautiful clear blue sky's and sunshine!

Another yummy breakfast!

Then it was time to hit the beach and do some more exploring.

We headed back into the dune tracks to explore them some more.

The tracks were fun and occasionally we were rewarded with views of the ocean.

We saw lots of roo's.

We returned to camp and spotted some dolphins swimming close to the foreshore.

Relaxed with another cold one.

It was quite windy by this point and the tent needed all guy ropes and pegs to keep it secured.

Before hitting the beach and heading North again.

We headed back into civilisation.

And were greeted with stunning views.

In complete contrast to the wild waters of the East coast, the sheltered waters of the West coast were beautiful and calm.

As it was now low tide we headed back to drive the beach we couldnt drive the previous day.

The contrast of the pure white sand and turquoise blue ocean was stunning!

We drove the entire beach.

Then drove back across the island to Main Beach.

And headed South back to camp.

Fire was soon going again.

Marinaded steak and veggies for dinner.

Lexi had more fun in the water.

Followed by a nice exfoliating sand rub!

We relaxed with a few more cold ones around the fire.

And were treated to an amazing sunset sky!

The next morning I was awake nice and early.

And was rewarded with a beautiful sunrise over the Pacific.

We packed the camp up and headed for the boat.

Which soon arrived and after unloading its cargo.

We were first to board.

They had to lower the ramp for the upper deck for us as it was a full house.

And we were off!

Sadly facing backwards but the water was calm and it was a pleasant journey.

We soon reached the main land.

And 40 minutes later we were home!

It was an amazing trip and so close to home! We will get to Fraser, but its 4+ hours drive North

versus less than an hour for North Stradbroke and we can take Lexi.

Going mid week helped ensure we had an amazing camping spot all to ourselves that felt like it could be a thousand k's from anywhere, yet it was only a 40 min drive back to civilisation on the island and on a clear day we could see the skyscrapers of Surfers Paradise to the South!

We will definitely be back again, although I want to do a forest camp next time as the last few trips we've done have been beach trips.

A bit of cutting and welding later and it was done.

I also decided to refit the anti roll bar (or sway bar as their called here), to make LJ a bit more road friendly now I'm not driving anything too extreme.

It hadnt been fitted for 6 years so it took a little bit of working out to remember how it bolts on.

Then LJ was ready for the trip!

We wanted to go to Fraser Island or Moreton Island but nbeither of them allow dogs, unfortunately.

So we decided to head to North Stradbroke Island instead where dogs are welcome!

A quick look at the map reveals just how close it is to where we are in Oxenford.

Less than an hour to the ferry terminal.

We booked to stay at the Southern end of Main Beach on the East Coast, where the blue dot is.

We got LJ fully loaded on Monday morning.

Got to the ferry terminal just in time after some nightmare traffic on the motorway.

And we were soon on the boat.

40 minutes later we were on the island and we were soon on the tracks.

Quite a cloudy overcast day but the beach and water still looked beautiful.

We headed South down Main Beach towards our camp.

The tracks leading into the camping areas behind the dunes were all marked with numbers.

These tracks were a lot of fun and quite challenging in places as they wound their way in and the dunes.

Not liking any of the first camping spots as they had no beach views, we rejoined the beach and headed further South.

We found a beautiful spot overlooking the beach and our nearest neighbor was a few k's away!

The fire was soon lit.

And Lexi was having the time of her life on the beach.

I cooked us dinner.

We spent the evening relaxing round the fire with a few cold ones.

The next morning the fire was soon re-lit and the kettle boiling.

While we tucked into the yummy sausage, egg, cheese and tomato sandwiches

Lexi started eating the fire wood!

I decided to drop the tyre pressures a bit more as I'd gone down to 20psi when we got off the ferry but found I was struggling for traction at times in the soft sand.

We hit the beach and headed North.

And soon found ourselves briefly back in civilisation.

We headed onto one of the beaches at the top of the island.

Sadly the tide was in so we couldnt drive along this beach just yet.

So we carried on exploring the top of the island.

We got a bit of rain and decided to head back to camp.

It brightened up a bit and we sat and had a few cold ones.

It had all been too much for Lexi who had a good sleep.

But not for too long.

I got dinner on.

Chicken satay steaks and veggies.

We then relaxed round the fire with a few more cold ones.

The next morning we awoke to beautiful clear blue sky's and sunshine!

Another yummy breakfast!

Then it was time to hit the beach and do some more exploring.

We headed back into the dune tracks to explore them some more.

The tracks were fun and occasionally we were rewarded with views of the ocean.

We saw lots of roo's.

We returned to camp and spotted some dolphins swimming close to the foreshore.

Relaxed with another cold one.

It was quite windy by this point and the tent needed all guy ropes and pegs to keep it secured.

Before hitting the beach and heading North again.

We headed back into civilisation.

And were greeted with stunning views.

In complete contrast to the wild waters of the East coast, the sheltered waters of the West coast were beautiful and calm.

As it was now low tide we headed back to drive the beach we couldnt drive the previous day.

The contrast of the pure white sand and turquoise blue ocean was stunning!

We drove the entire beach.

Then drove back across the island to Main Beach.

And headed South back to camp.

Fire was soon going again.

Marinaded steak and veggies for dinner.

Lexi had more fun in the water.

Followed by a nice exfoliating sand rub!

We relaxed with a few more cold ones around the fire.

And were treated to an amazing sunset sky!

The next morning I was awake nice and early.

And was rewarded with a beautiful sunrise over the Pacific.

We packed the camp up and headed for the boat.

Which soon arrived and after unloading its cargo.

We were first to board.

They had to lower the ramp for the upper deck for us as it was a full house.

And we were off!

Sadly facing backwards but the water was calm and it was a pleasant journey.

We soon reached the main land.

And 40 minutes later we were home!

It was an amazing trip and so close to home! We will get to Fraser, but its 4+ hours drive North

versus less than an hour for North Stradbroke and we can take Lexi.

Going mid week helped ensure we had an amazing camping spot all to ourselves that felt like it could be a thousand k's from anywhere, yet it was only a 40 min drive back to civilisation on the island and on a clear day we could see the skyscrapers of Surfers Paradise to the South!

We will definitely be back again, although I want to do a forest camp next time as the last few trips we've done have been beach trips.

Cracking sunset pics Ben. You have some fantastic driving tracks on your doorstep. Thanks for sharing your trip Ben. All the best to you and Bec.

What a great trip, so close but a complete change. You all look very happy, and as you know by now, that's what's important in life.

Thanks for sharing all those lovely photos mate.

Thanks for sharing all those lovely photos mate.

Similar threads

- Replies

- 6

- Views

- 376