In my shed I seem to have about 3 or 4 old compressors which don't seem to work that well. Handed over to me from friends that have left Dubai for Oz or whatever.

So until I have the time to install the new double pumper, I make a ARB compressor in a box. My friend has one of these which I used for inspiration.

So I bought a toolbox and had a go at making my own :

I got some new button headed M4s to replace these stupid cheese heads, will get those installed shortly.

Only issue I had was the pressure switch doesn't seem to cut the power. I have it wired in line with the switch side of the relay, since it is only rated at 5A.

I have a spare one, if that doesn't work I will steal the pressure switch off my friend's compressor as he is away in Spain on holidays. Not sure why he left the keys with me

Also when installing the over sized radiator, I lost the central bracket which supports the bonnet latch. When you went to close the bonnet, the whole cross member was twisting and failing to lock. The only way to close it was to take the bonnet rod off, poke it though the grill and use the end of the rod to hold the latch mechanism with one hand and slam the bonnet shut with the other.

Although it was a good party trick, it got tired quickly so I made a 'Z' profile bracket to tie into the grille. Even though it was light aluminium, it does the trick. Will upgrade to steel when I get organised and by some more flat bar.

After finishing the compressor and pumping up 4 tires from last weekend, it was still relatively early so I decided to get started on my next idea. The new electric fan moves a lot of air through the radiator, but once on that side the is the large block in the way and no where for the hot air to go. After a quick run in the desert I had noticed the area of bonnet above the front of engine was too hot to touch.

So I start installation of louvres to let the hot air up and out. Got the thing fitted and aligned, then 8 holes drilled and riv-nuts installed :

It is about 2mm shorted overall from the spacing of the fold down windscreen support brackets. I think it looks alright but more important is exactly in the 'hot spot'. I bought some proper length button head bolts to replace these temporary ones. Next step is to cut out the sheet metal through to the inside. At this stage the idea was to remove the outer skin only, and not cut through the support ribs on the underside.

Sorry for the blurry photo, but the underside view shows roughly where the cut outs will be in red markup :

Going to take my time on this, as there will be hardly any 'replacement' bonnets I could find locally as this is a grey import vehicle in this market.

I also need to finish making the wooden template for the relay board and doing a mock up for confirming the fixing holes and checking clearances.

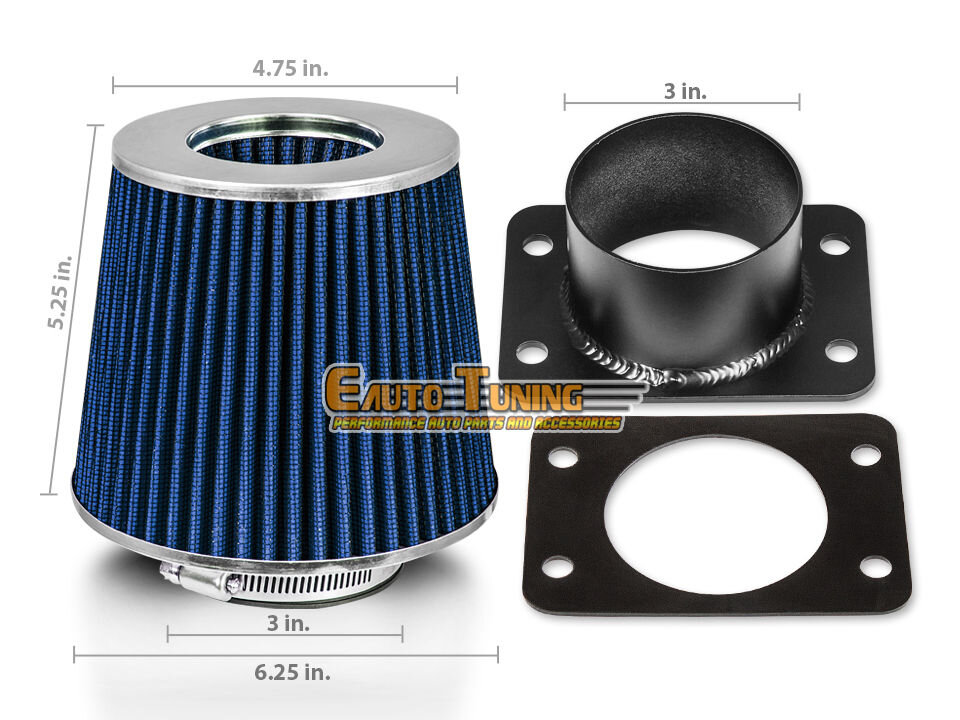

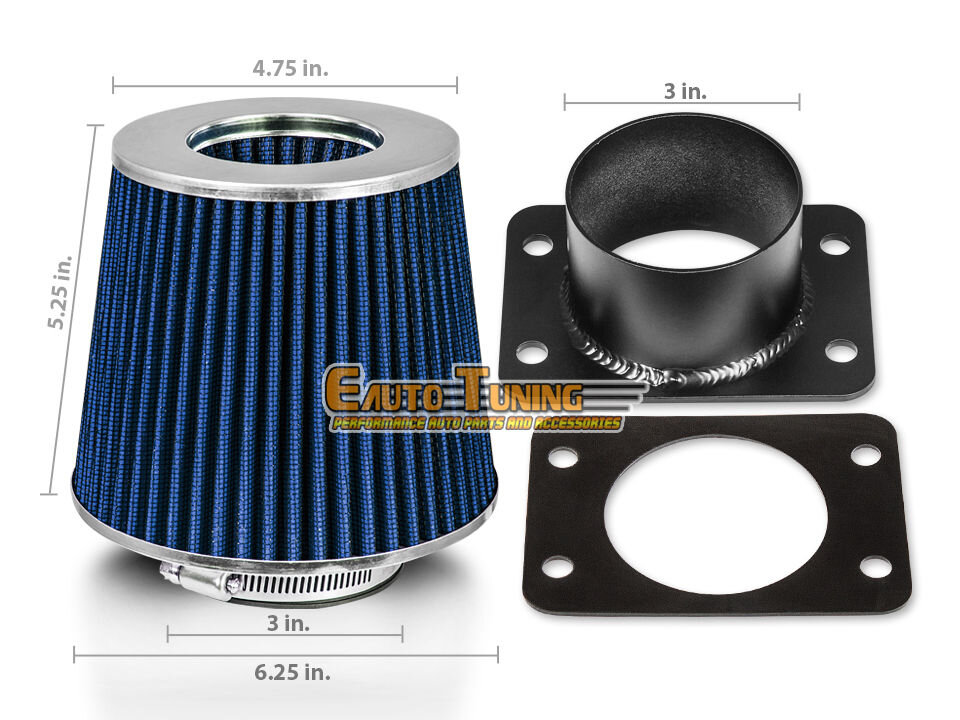

I bought a replacement air filter and an adapter plate to mount it properly. The previous filter is buggered and the rubber is torn, and the adapter plate is a home made by previous owners mechanic. Will have to post pics of it when I remove, it is quite bad.

Something similar to this is going on. I need a pod filter because I don't have the original airbox, not because of the extra 100 hp it is sure to release.