Iwan

Well-Known Member

- Joined

- Mar 28, 2011

- Messages

- 1,906

- Country Flag

I agree with you from research.. I do like the front plates like yours and they are easily available (iron man).. when I did the experimental offset bushes on the lj70 (junk) it resulted in the steering rod touching the radius arm as you described.

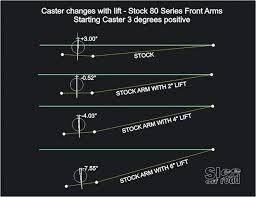

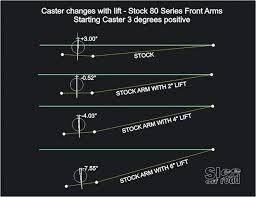

So with dropping the back of the arm, they suggest to lower the amount of the lift. I like the principle as it keeps the radius arm as stock anglewise.. not sure but braking at higher speed you are getting a direct line of force back to the chassis. Unlike the lower in the diagram.. I'm sure that steeper the angle the more stress to the components at high speed braking.. just a thought.

All good information thanks

So with dropping the back of the arm, they suggest to lower the amount of the lift. I like the principle as it keeps the radius arm as stock anglewise.. not sure but braking at higher speed you are getting a direct line of force back to the chassis. Unlike the lower in the diagram.. I'm sure that steeper the angle the more stress to the components at high speed braking.. just a thought.

All good information thanks